Auxetic composite material pipeline and delivery line

A technology for composite materials and transportation pipelines, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve problems such as pipeline collapse, pipeline system collapse, and metal pipelines are easy to corrode, so as to overcome collapse or buckling, improve The effect of fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0037] A typical implementation case of the present invention provides a pipe made of auxetic composite material.

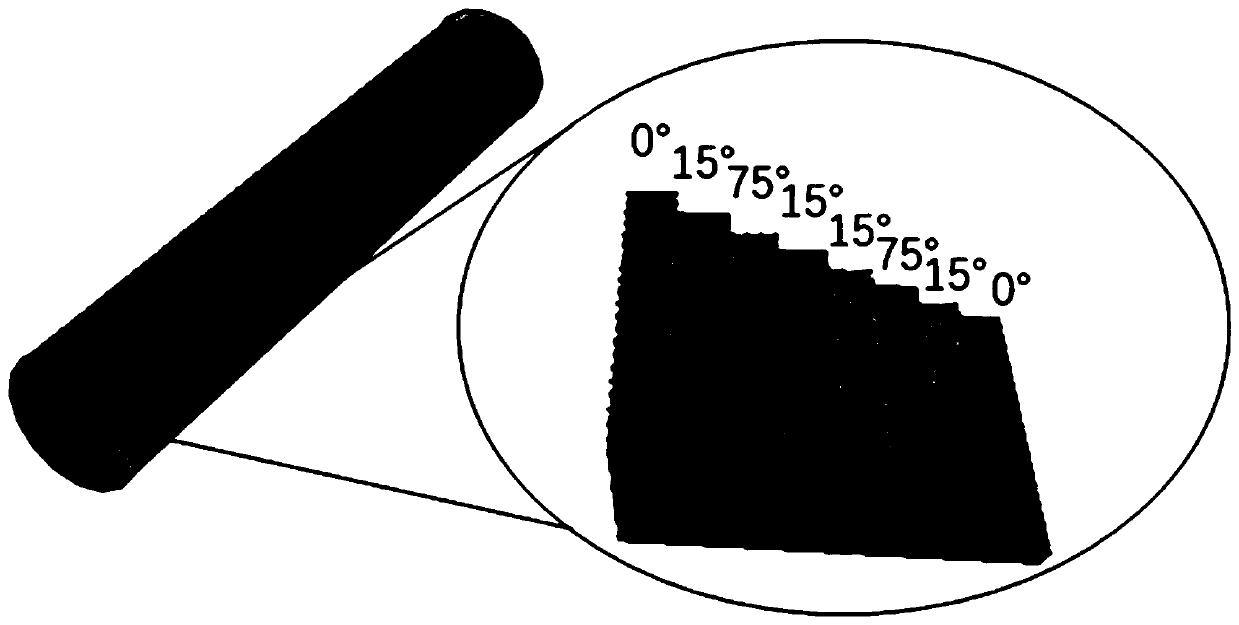

[0038] The material is formed by wet winding. After the continuous carbon fiber is impregnated with polyurethane or epoxy resin, it is spirally wound on the mandrel according to the required laying angle under a certain tension, and then heated and cured.

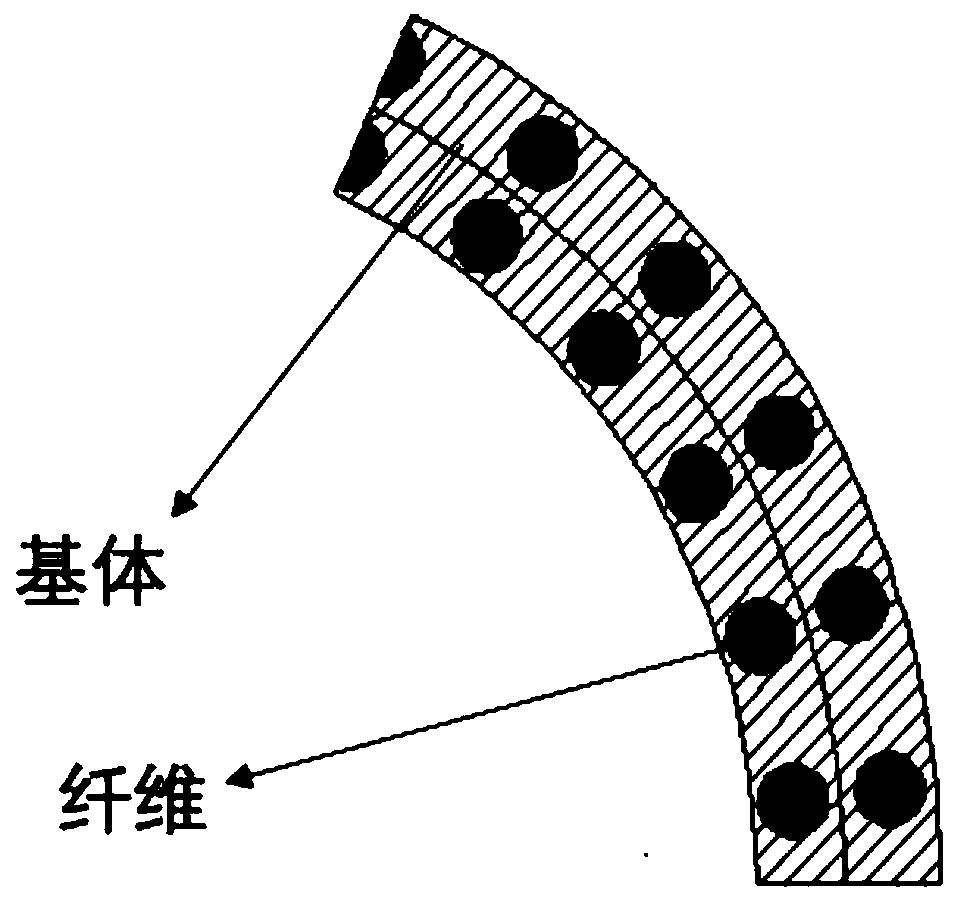

[0039] The pipeline includes a section of pipe body, and the pipe wall of the pipe body includes 2N layers of concentric layers arranged in sequence, where N is a positive integer greater than or equal to 2, that is, at least 4 layers of layers, and each of the Each layer includes a matrix and a reinforcement embedded in the matrix, where the angle between the reinforcement corresponding to the nth layer and the 2N+1-nth layer is the same as that of the pipe axis, that is, the N layers near the axis The angle distribution of the layup and the other N layers away from the axis is symmetrical; the reinforcements...

Embodiment 2

[0057] Another typical embodiment of the present invention provides a delivery pipeline using Embodiment 1.

[0058] The conveying pipeline includes the auxetic composite material pipeline described in Embodiment 1, and the pipe body can be used alone for conveying materials such as oil and gas, especially for offshore conveying pipelines, as follows:

[0059] The pipeline needs to bear the load in the process of transporting materials, and then, its load is not the same under different working conditions, and it may appear that the load is higher than it can bear, resulting in rupture or failure. At this time, using the Auxetic composite piping can overcome this problem;

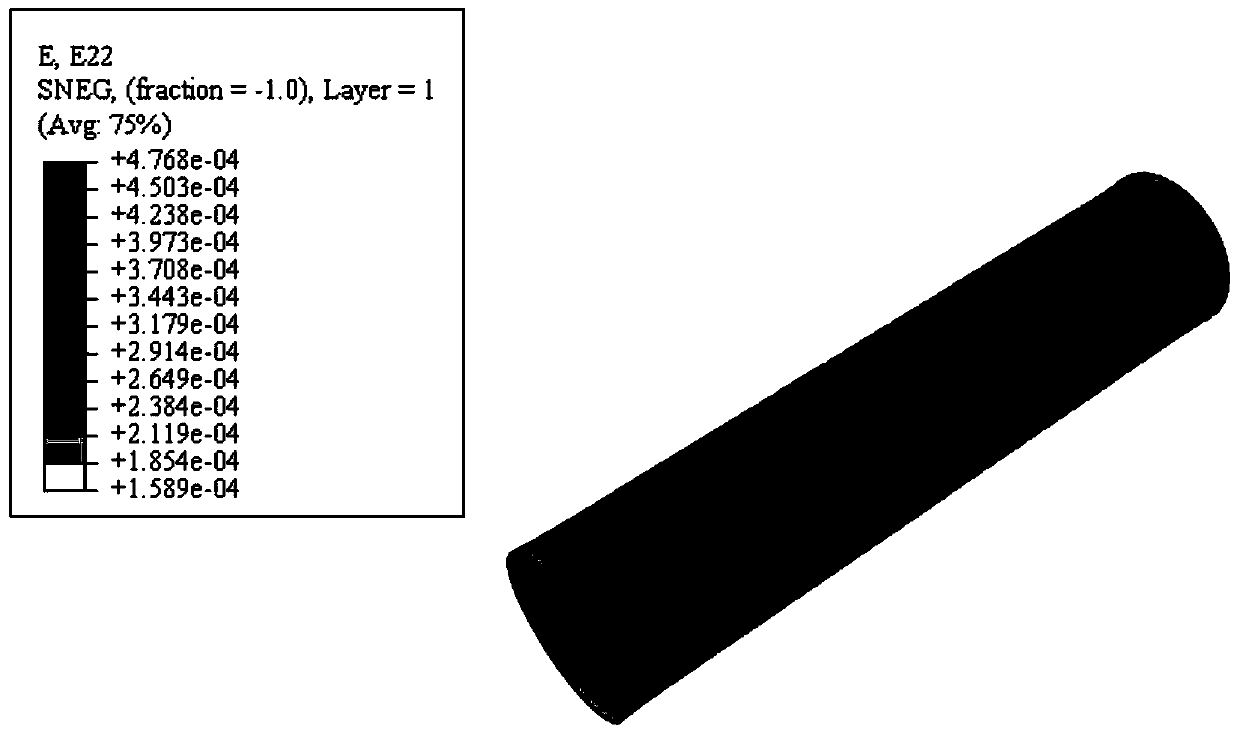

[0060] In the first working condition, the steel pipe and the auxetic composite pipe provided by this application have different deformation behaviors when they are subjected to internal pressure. Such as Figure 6 As shown, for the existing commonly used steel pipes, the radial Poisson's ratio is positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com