Three-dimensional roughness description method for rock mass structural surface based on borehole camera technology

A structural surface and roughness technology, which is applied in the field of three-dimensional roughness description of rock mass structural surfaces, can solve problems such as inaccuracy and achieve the effect of ensuring authenticity and sampling data is true and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

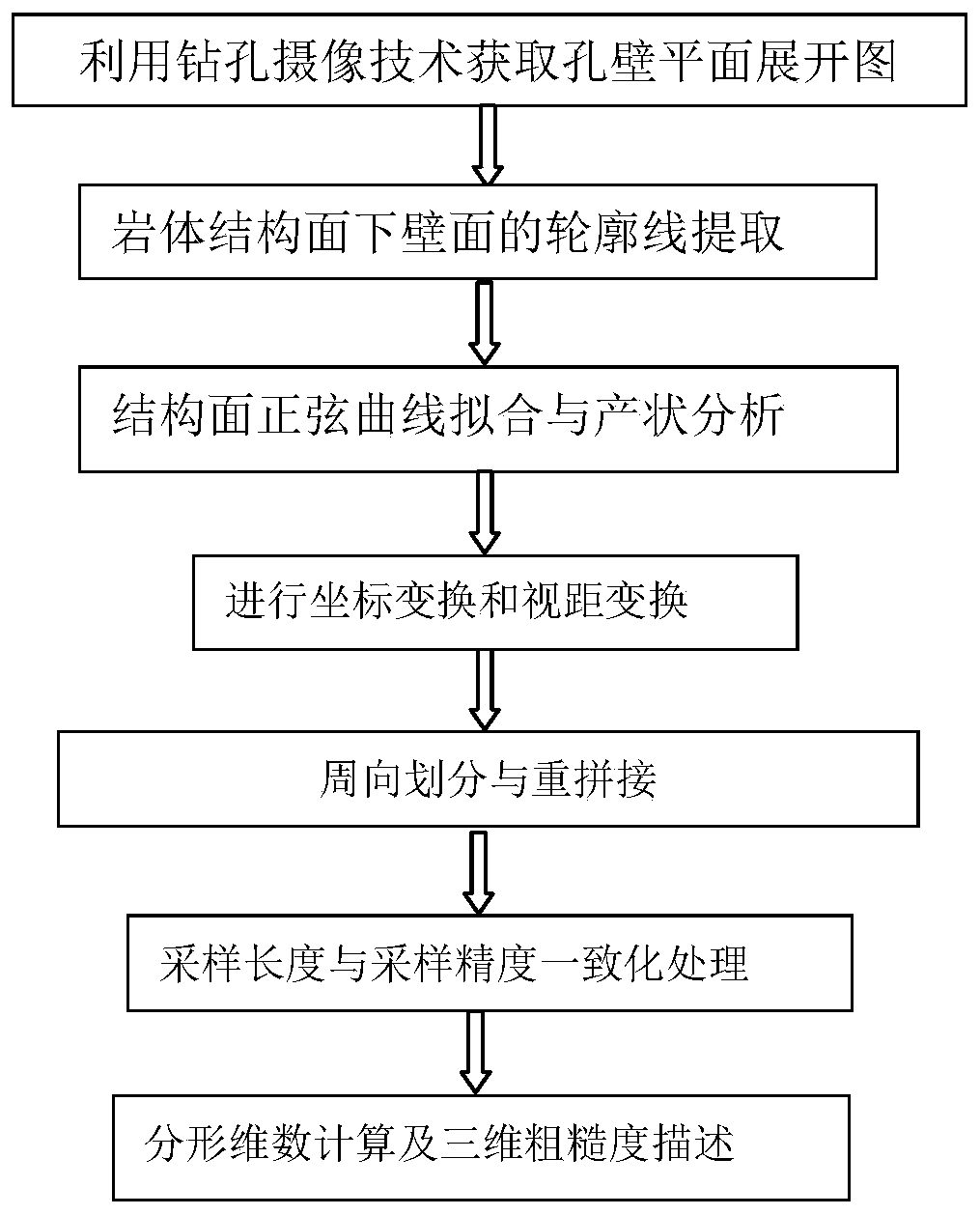

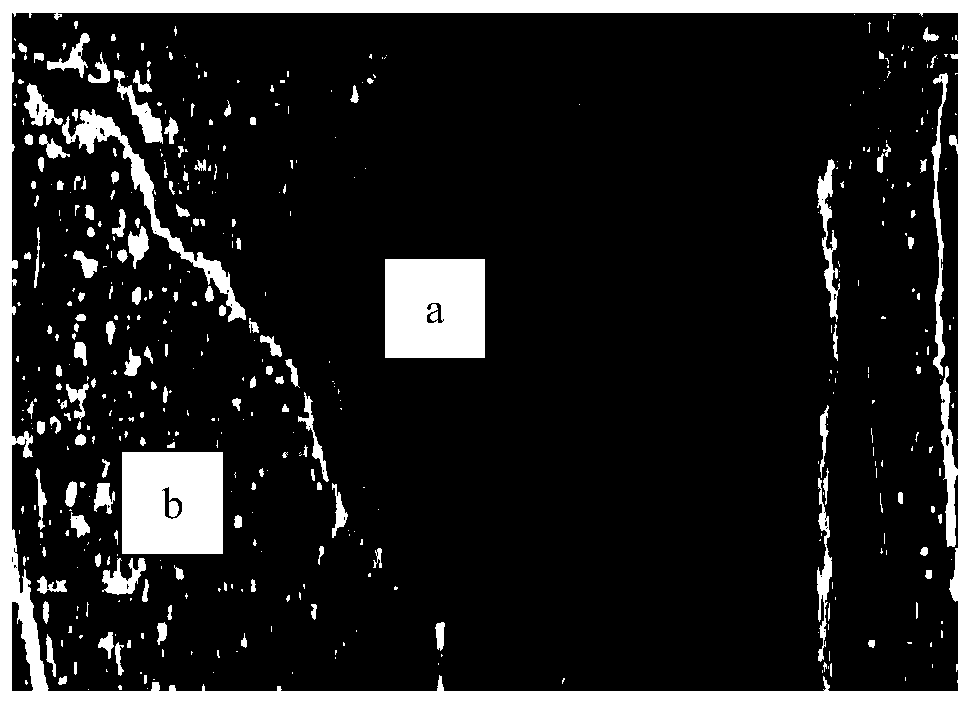

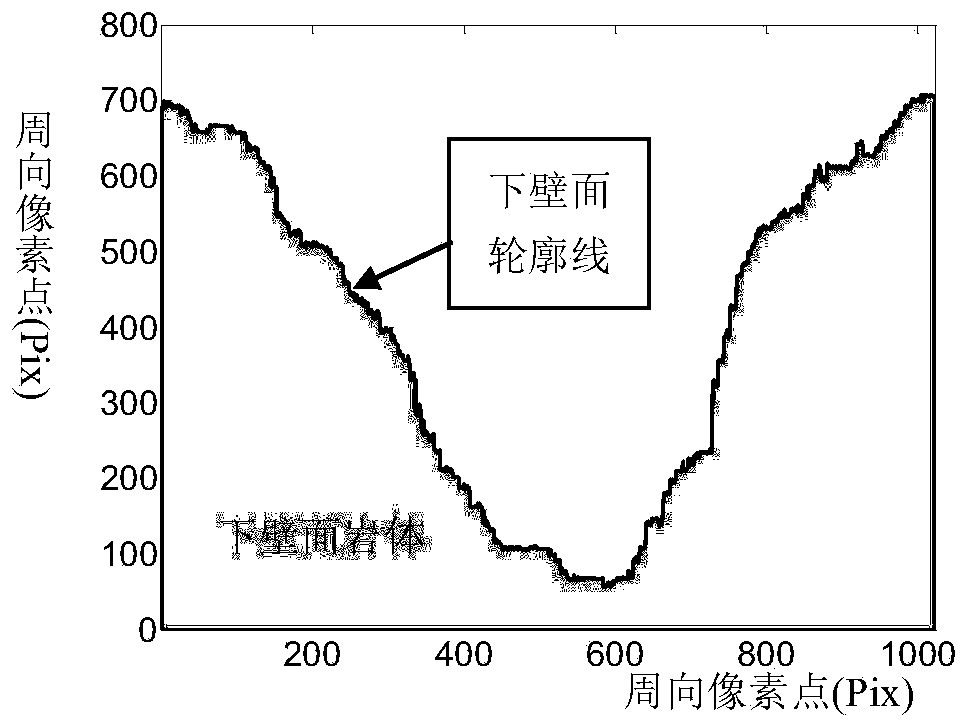

[0052] A method for describing the three-dimensional roughness of a rock mass discontinuity surface based on borehole imaging technology. The specific steps are as follows on the premise that borehole images have been acquired, and the actual measured borehole image data is taken as an example to illustrate in detail.

[0053] A method for describing the three-dimensional roughness of rock mass structural surfaces based on borehole camera technology, the steps of which are:

[0054] Step 1. Use the digital drilling camera system to obtain a panoramic view of the hole wall;

[0055] The digital drilling camera system is a new set of advanced intelligent exploration equipment. The digital drilling camera system integrates electronic technology, video technology, digital technology and computer technology, and performs undisturbed in-situ camera recording and analysis on the inner wall of the hole from a panoramic perspective. By directly studying the borehole wall, the disturbi...

Embodiment 2

[0118] The present invention will be further described by taking the general application as an example below.

[0119] A method for describing the three-dimensional roughness of a structural surface of a rock mass by drilling camera technology, comprising the following steps:

[0120] Step 1. Use the digital drilling camera system to obtain a panoramic view of the hole wall;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com