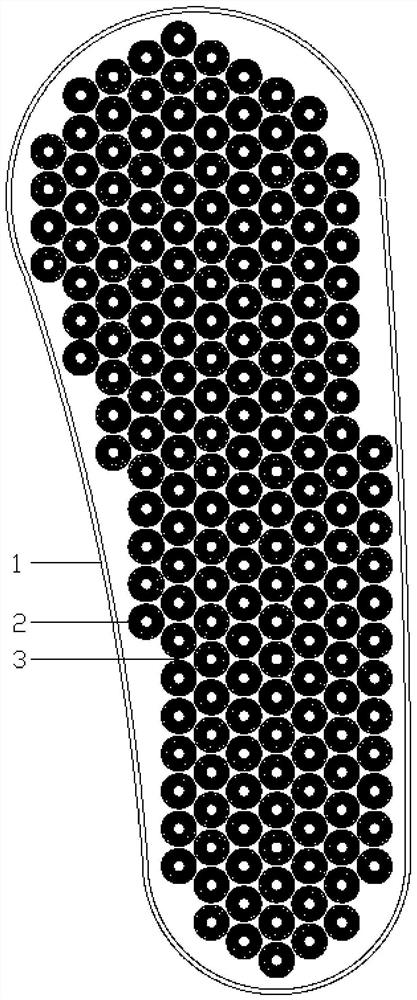

A deformable micro-suction cup bionic, impurity-removing, wear-resistant, non-slip sole structure

A technology of anti-slip and suction cups, which is applied to soles, footwear, clothing, etc., can solve the problems of non-slip and wear-resistant effect and single anti-slip structure, and achieve the effect of novel design, simple structure and increased anti-slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

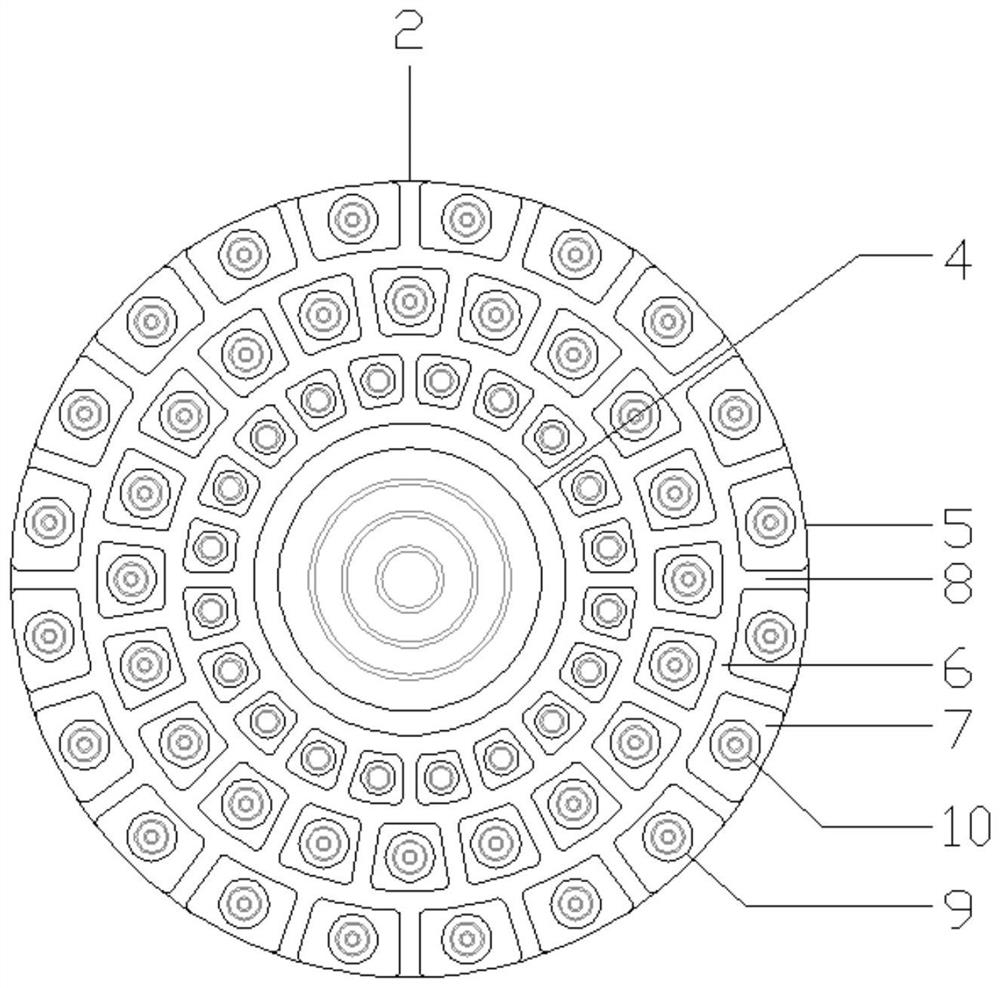

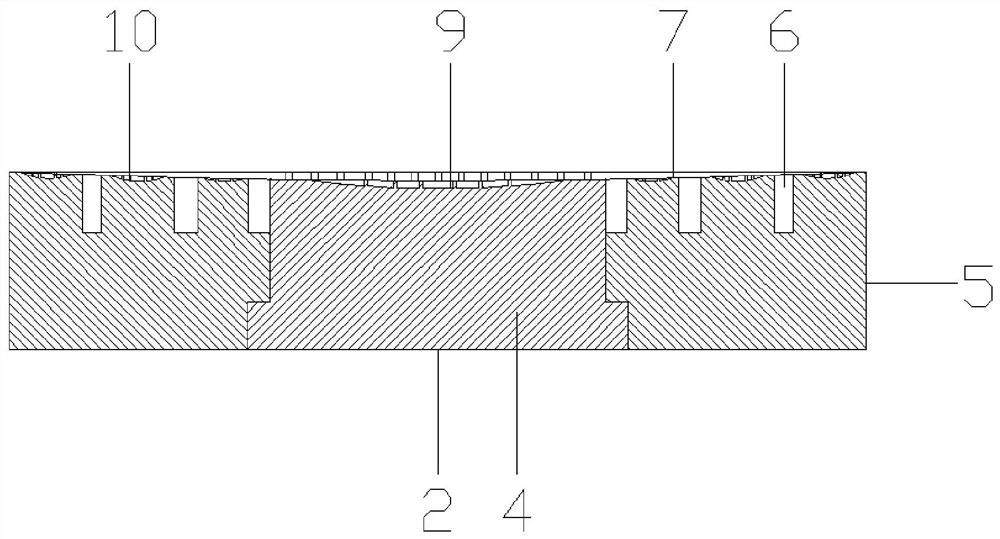

[0039] In actual use, when the user walks on the ground using the sole of the non-slip structure of the present invention, the outermost annular anti-slider on the non-slip structure is in contact with the ground, and then, in the human body's own gravity, the user is in front of the ground In combination, the arcuate groove on the non-slip boss is squeezed to adsorb the smooth road to prevent slipping. Among them, since the non-slip boss is made of rubber, it has a good wear-resistant anti-slip effect, and can be deformed when the force is large, and after the long-term use of wear, the anti-skid boss on the inner ring anti-slider is The ground is fitted to further increase the anti-slip wear resistance effect of the anti-slip structure. Further, the disposed anti-skid disc is made of a hard plastic, not only to support the non-slip slip of the sole, but also after the inner ring anti-slider is deformed or worn, it can always maintain the non-slip effect of the sole. In addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com