Small robot unloading rotary joint

A technology of rotating joints and robots, which is applied in the field of robots, can solve the problems of large volume and weight, and achieve the effects of improving bearing capacity, reducing volume and total volume, and reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

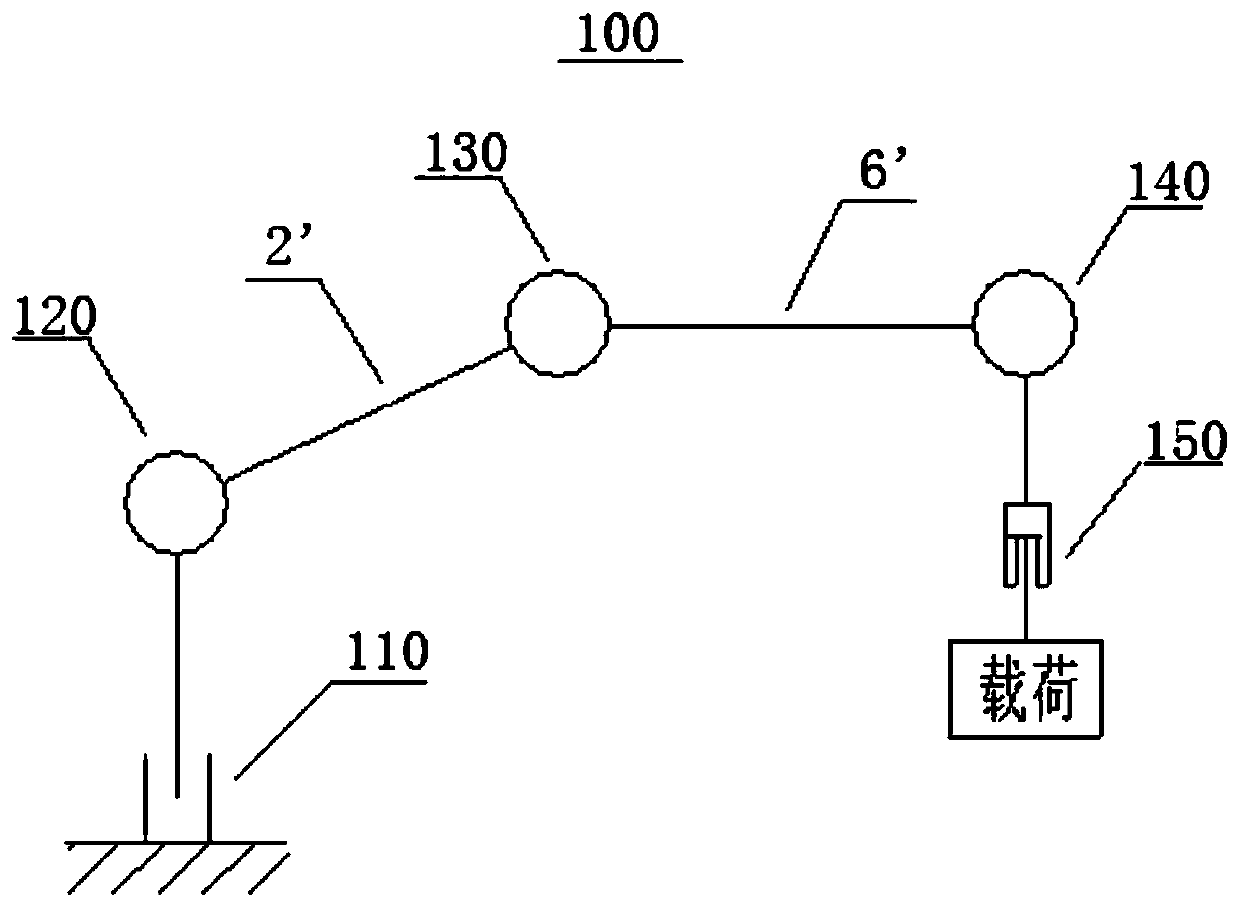

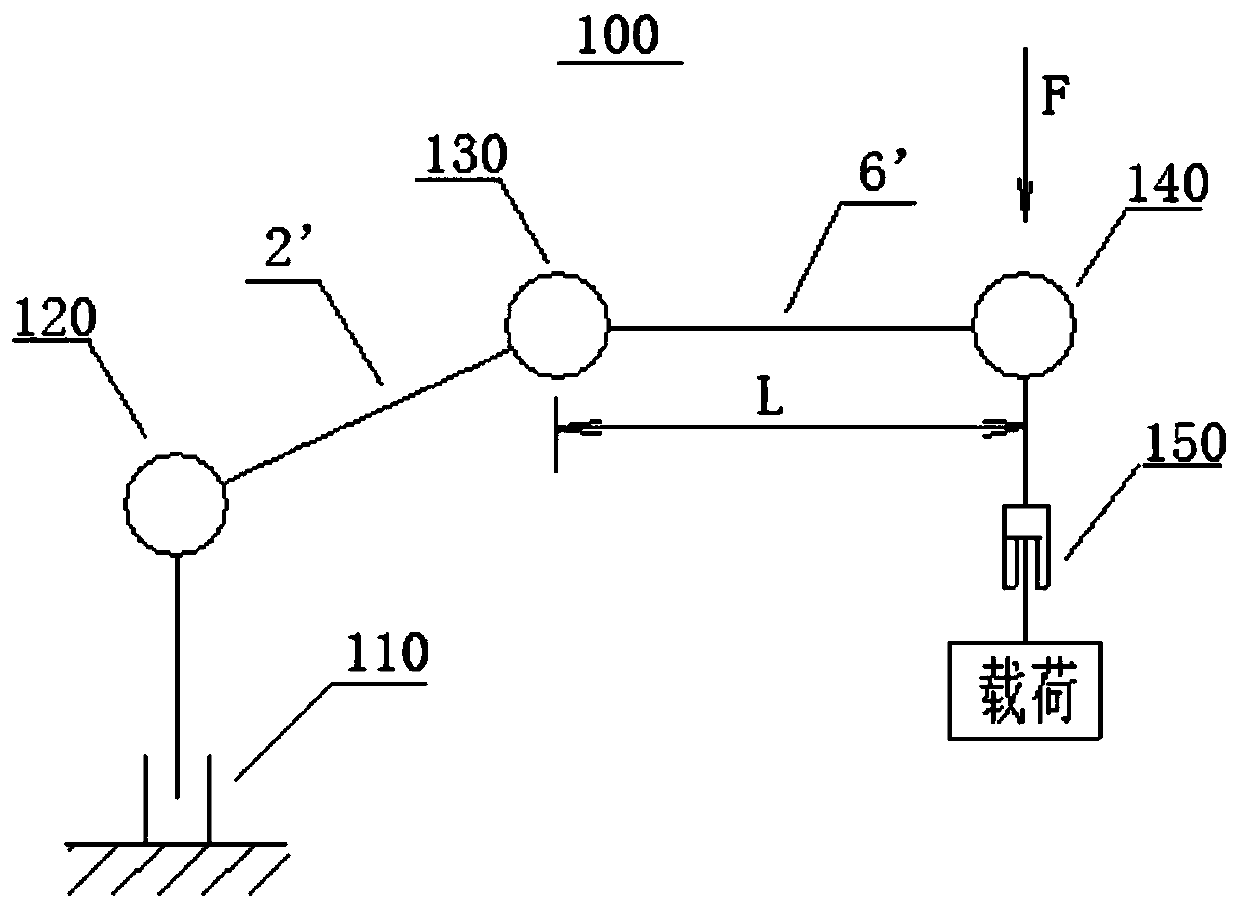

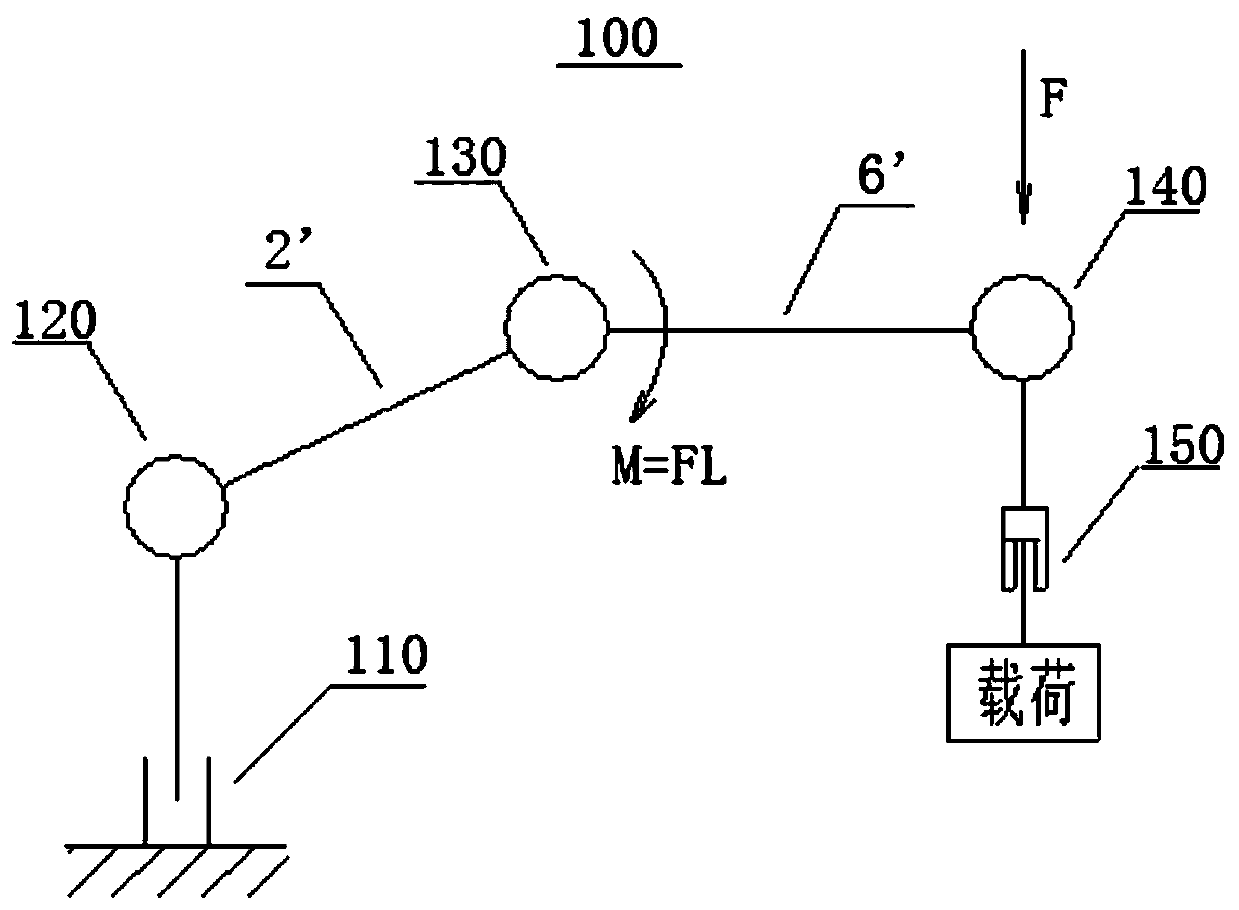

[0026] Such as Figure 1-5 As shown, the existing articulated robot 100 includes a first joint 110, a second joint 120, a third joint 130, a fourth joint 140, a fifth joint 150, a big arm 2' and a small arm 6'. The radial load F and torque M on the third joint 130 are as follows figure 2 and 3 shown. Such as Figure 4 As shown, the existing third joint 130 includes a motor 1', a motor seat plate 7' and a reducer 3'. Such as Figure 5 As shown, on the output shaft, the load F causes the flexspline 33' and the output shaft of the reducer 3' to bend, the torque M causes the flexspline 33' and the output shaft to twist, and the flexspline 33' and the output shaft are subject to bending moment Combined with the torque, when the flexspline 33' and the output shaft of the speed reducer 3' rotate, the loads on the flexspline 33' and the output shaft are alternating loads. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com