Board slotting machine

A technology for slotting machines and wood boards, which is applied in the direction of slotting machines, mortising machines, wood processing appliances, etc., can solve the problems of increasing people, increasing workload, and reducing the efficiency of wood slotting, so as to prevent physical fatigue and reduce The effect of reducing workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

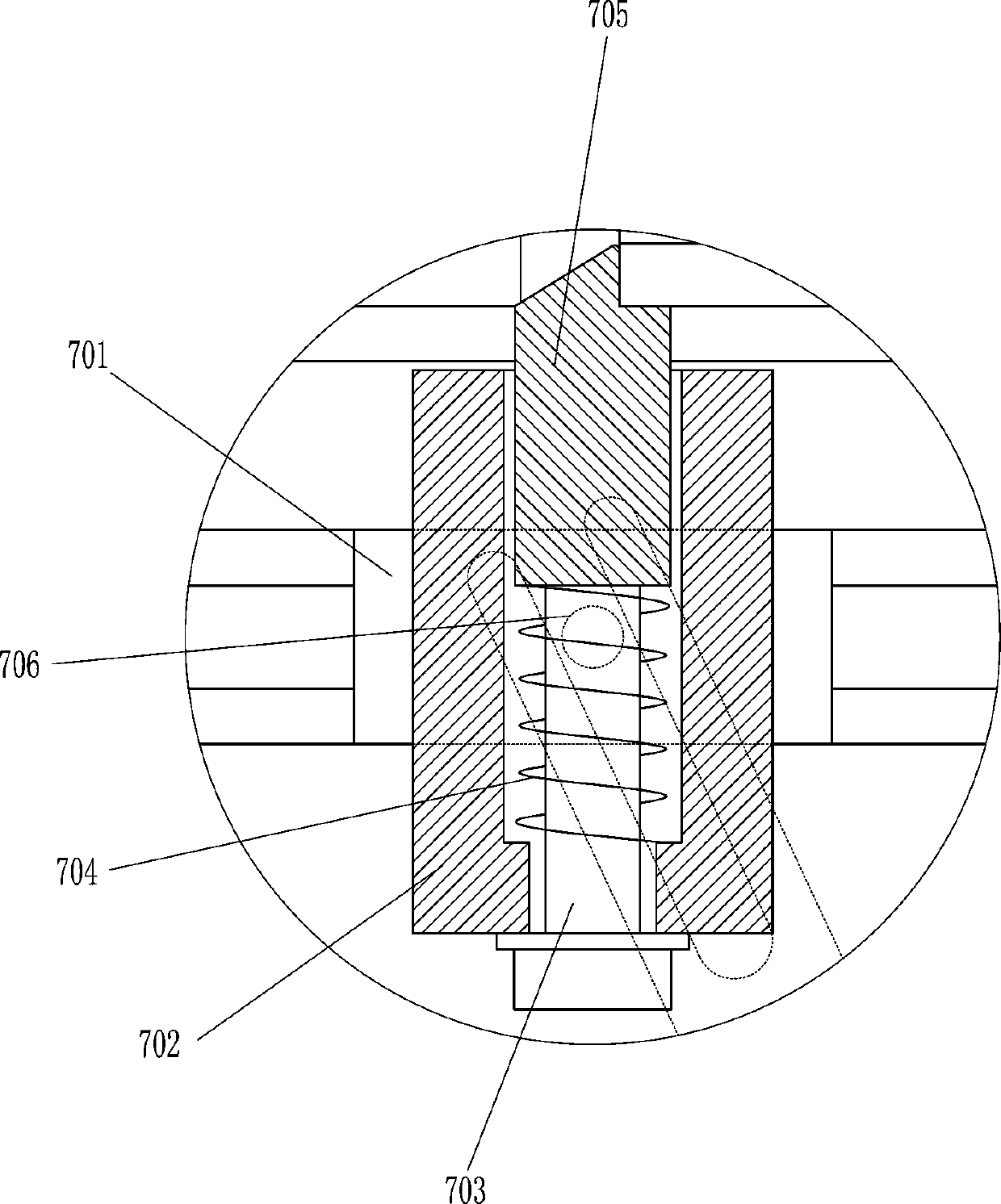

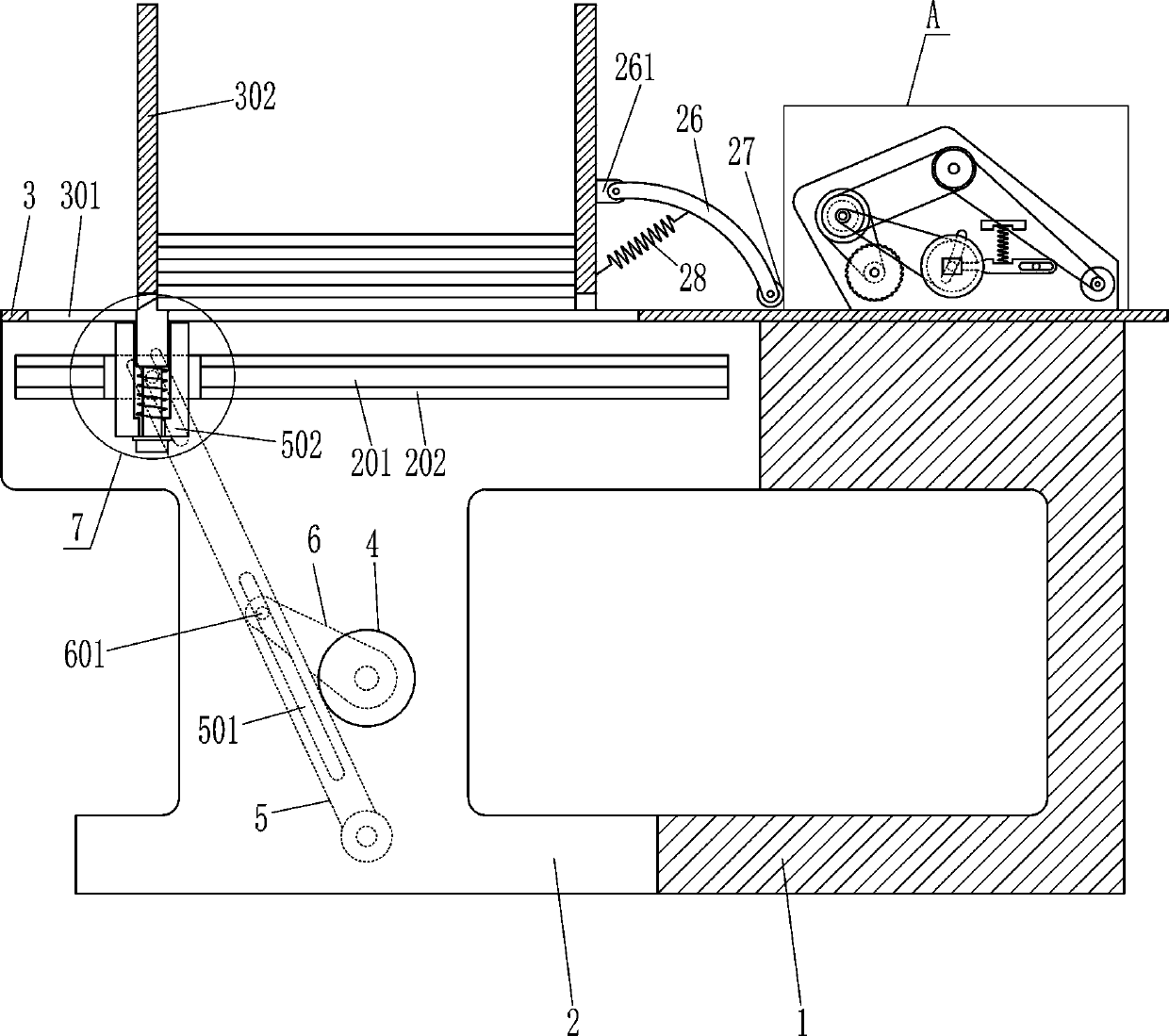

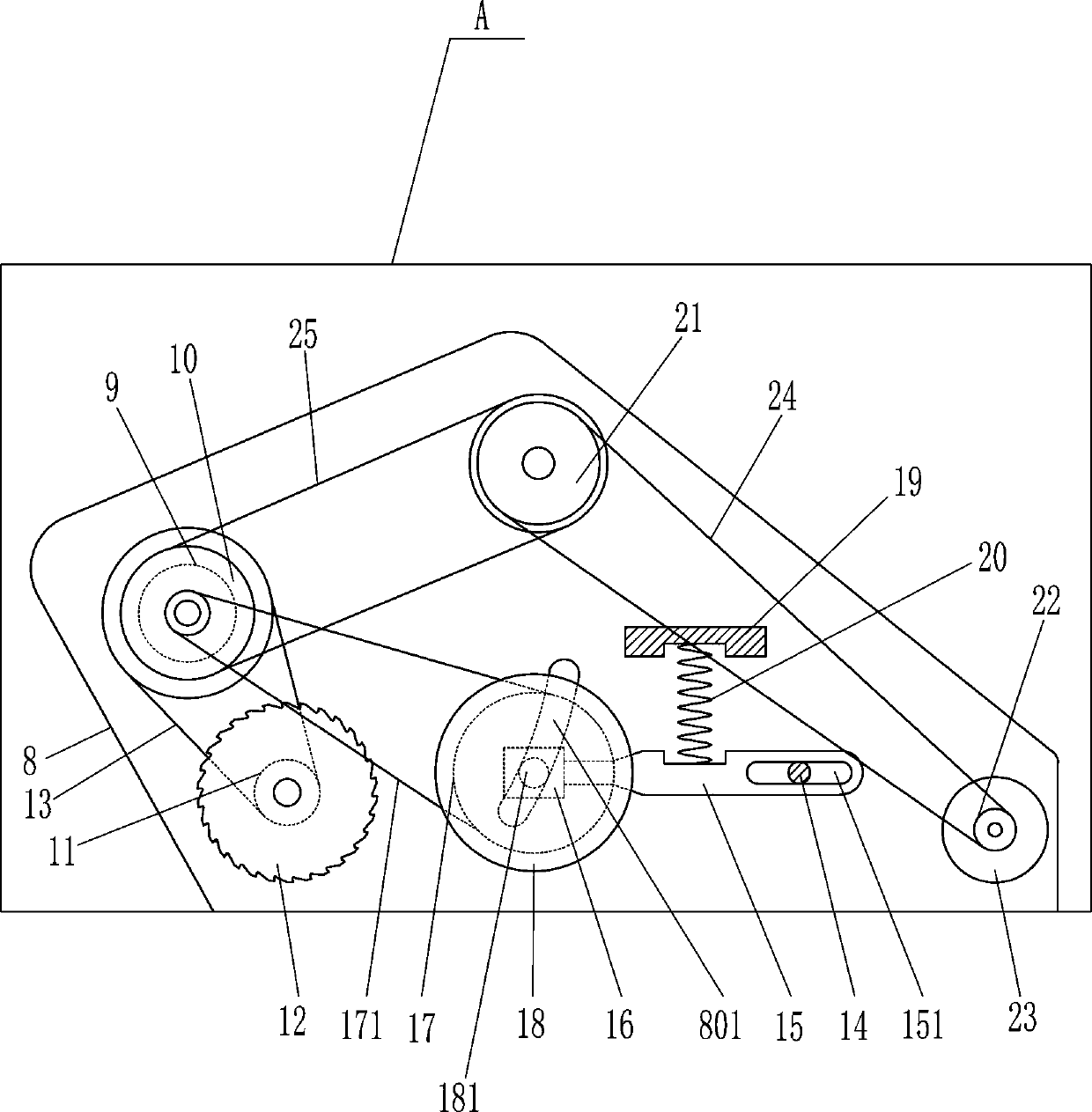

[0016] A wood slotting machine such as Figure 1-3 Shown, comprise first frame 1, second frame 2, guide bar 202, workbench 3, card frame 302, first motor 4, long fork 5, short fork 6, pin bar 601, push Material mechanism 7, the third frame 8, the second motor 9, three groove pulley 10, the first single groove pulley 11, cutting wheel 12 and the first belt 13, the left side of the first frame 1 is equipped with the first Two frames 2, the first frame 1 is connected with the second frame 2 by means of bolt connection, the top of the second frame 2 has a first opening 201, and the left and right walls in the first opening 201 are installed with Guide bar 202, a workbench 3 is installed between the tops of the first frame 1 and the second frame 2, the first frame 1 and the second frame 2 are connected with the workbench 3 by means of bolt connection, and the workbench 3. There is a second opening 301 in the middle of the left side of the top, and a wooden frame 302 that can hold ...

Embodiment 2

[0018] A wood slotting machine such as Figure 1-3 Shown, comprise first frame 1, second frame 2, guide bar 202, workbench 3, card frame 302, first motor 4, long fork 5, short fork 6, pin bar 601, push Material mechanism 7, the third frame 8, the second motor 9, three groove pulley 10, the first single groove pulley 11, cutting wheel 12 and the first belt 13, the left side of the first frame 1 is equipped with the first Two frames 2, the top of the second frame 2 has a first opening 201, a guide rod 202 is installed between the left and right walls in the first opening 201, between the tops of the first frame 1 and the second frame 2 A workbench 3 is installed between them, a second opening 301 is arranged in the middle of the left side of the top of the workbench 3, and a card frame 302 which can be placed on the plank is installed on the left side of the top of the workbench 3, which can drive the short swing bar 6 to rotate. The first motor 4 is installed on the bottom of ...

Embodiment 3

[0021] A wood slotting machine such as Figure 1-3 Shown, comprise first frame 1, second frame 2, guide bar 202, workbench 3, card frame 302, first motor 4, long fork 5, short fork 6, pin bar 601, push Material mechanism 7, the third frame 8, the second motor 9, three groove pulley 10, the first single groove pulley 11, cutting wheel 12 and the first belt 13, the left side of the first frame 1 is equipped with the first Two frames 2, the top of the second frame 2 has a first opening 201, a guide rod 202 is installed between the left and right walls in the first opening 201, between the tops of the first frame 1 and the second frame 2 A workbench 3 is installed between them, a second opening 301 is arranged in the middle of the left side of the top of the workbench 3, and a card frame 302 which can be placed on the plank is installed on the left side of the top of the workbench 3, which can drive the short swing bar 6 to rotate. The first motor 4 is installed on the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com