Double-fluidized bed double-particle heavy and inferior fuel pyrolysis and gasification device and method

A fluidized bed cracking and fluidized bed gasification technology, applied in the field of double fluidized bed double particle heavy and inferior fuel cracking gasification device, can solve the problem of high investment and operating costs, prominent processing and utilization problems, and demanding hydrotreating requirements. and other problems, to achieve the effect of high reaction efficiency and thermal efficiency, efficient mass transfer, and improvement of light oil yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

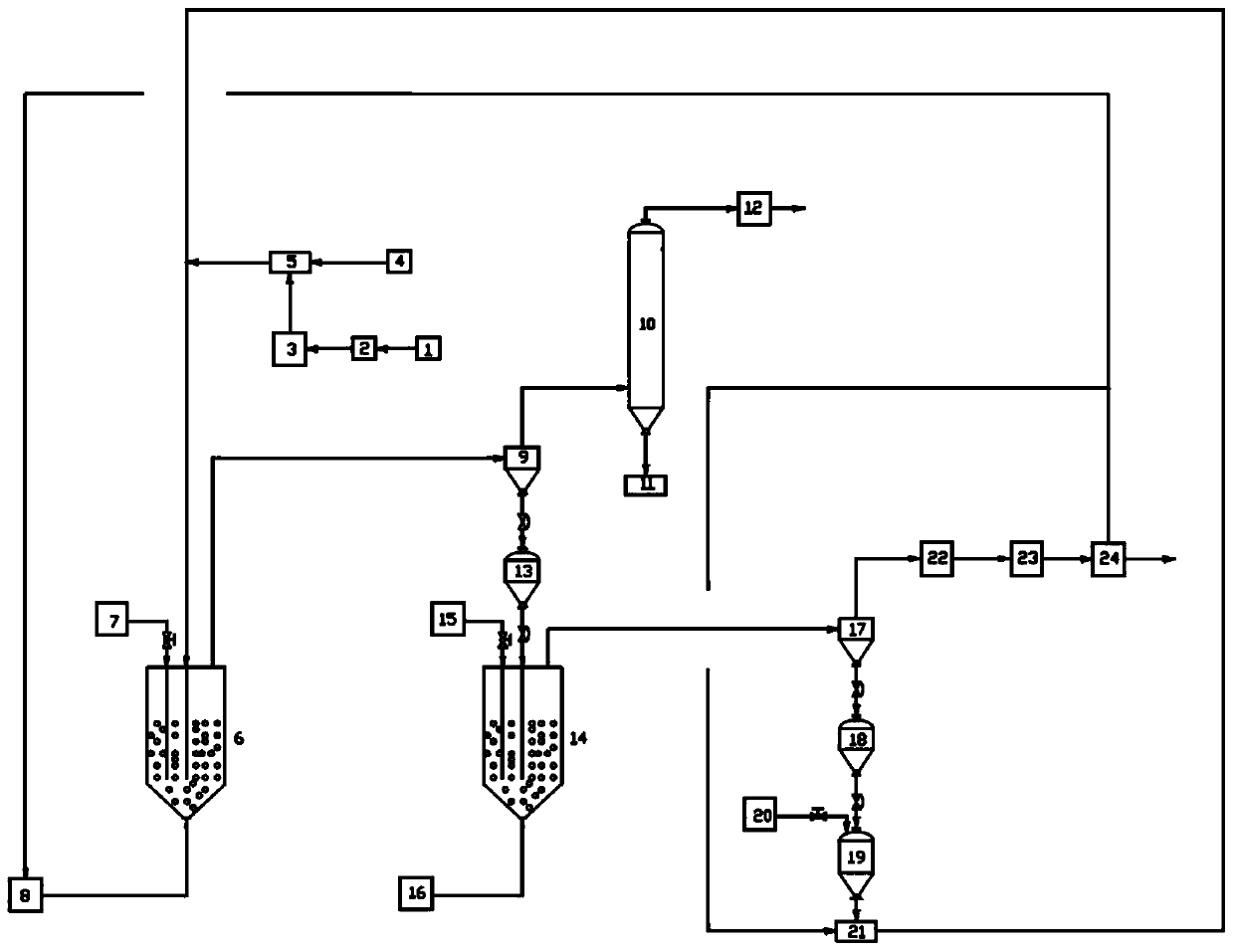

[0035] see figure 1 , the present invention dual fluidized bed double particle heavy low-quality fuel cracking gasification device, including cracking reactor system, gasification reactor system, cracking oil recovery system, particle circulation system.

[0036] The cracking reactor system includes a fuel heater 2, a fuel pump 3, and an atomizing mixer 5 connected in sequence; one end of the atomizing mixer 5 is connected to the high-pressure steam 4, and the other end is connected to the top material inlet of the fluidized bed cracking reactor 6 The bottom of the fluidized bed cracking reactor 6 is connected with the fluidized circulating gas heater 8, and the outlet of the top product of the fluidized bed cracking reactor 6 is connected with the inlet of the cracking gas-solid separator 9;

[0037] The gasificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap