Solid fuel dual fluidized bed partial gasification fractional conversion device and method

A technology of fluidized bed gasification furnace and solid fuel, which is applied in the direction of granular/powdered fuel gasification, gasification process, and production of combustible gas, which can solve the problem of high oxygen consumption, increased construction cost, and improved reaction conditions. Reaction equipment Manufacturing cost and maintenance cost, etc., to achieve the effect of low oxygen consumption, low equipment cost, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

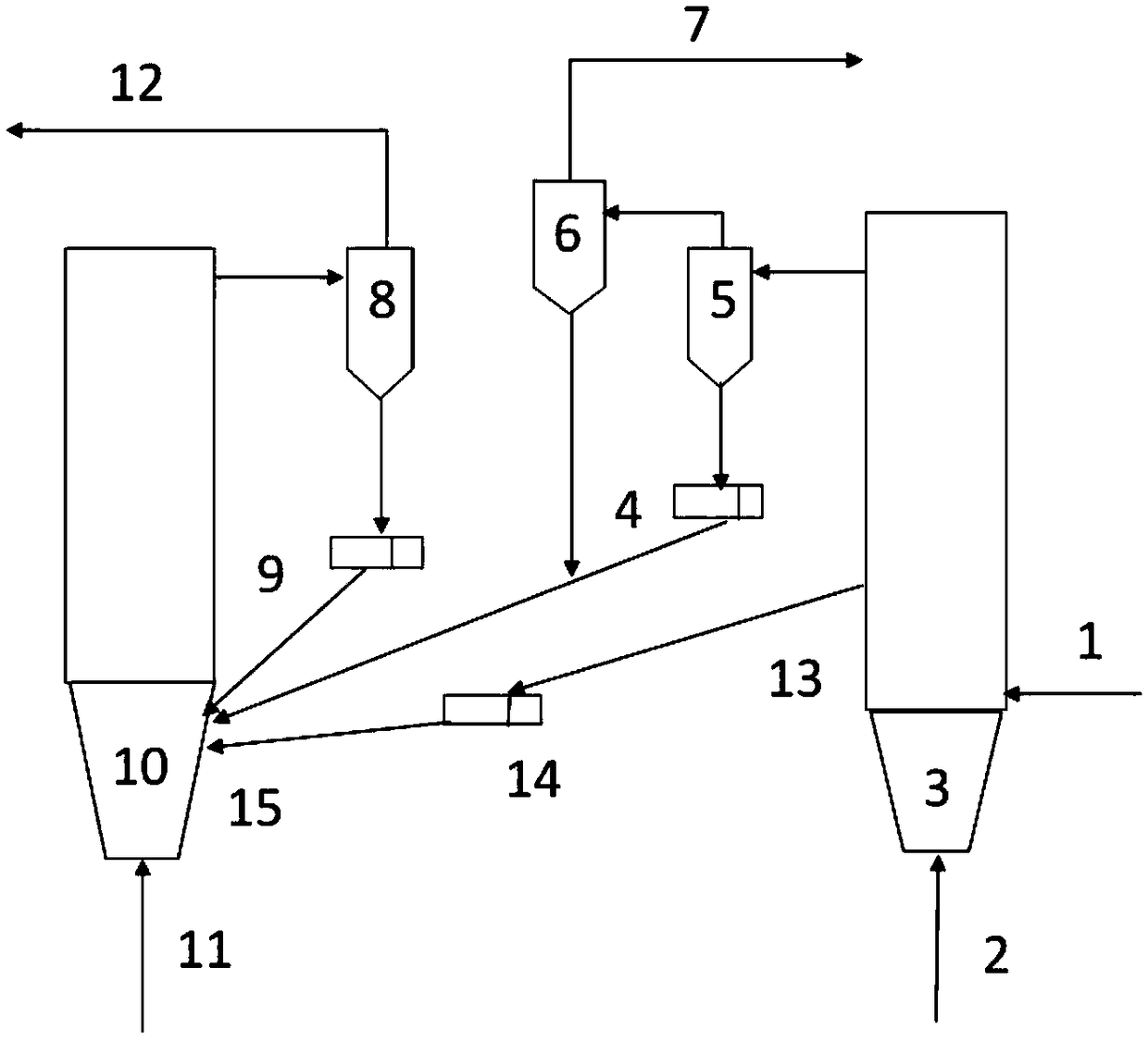

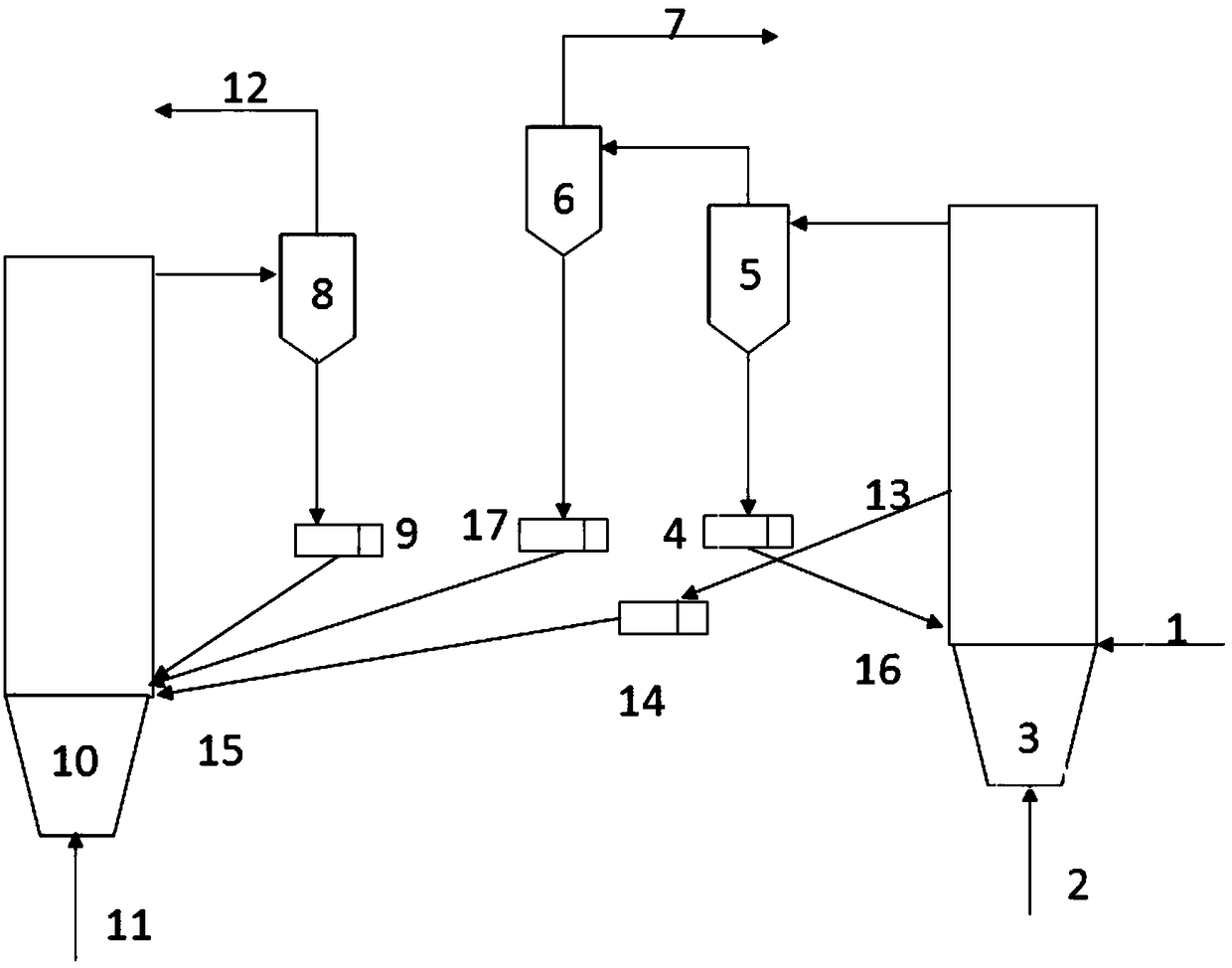

[0031] The solid fuel double fluidized bed partial gasification staged conversion device of the present invention includes a fluidized bed combustion furnace 10 and a fluidized bed gasification furnace 3 . The bottom of the fluidized bed gasifier 3 is provided with a gasification agent inlet 2, the middle and lower part is provided with a solid fuel feed port 1, the middle part is provided with an overflow port 13, and the top is provided with a synthesis gas outlet. The bottom of the fluidized bed combustion furnace 10 is provided with an air inlet 11, the middle and lower part is provided with a semi-coke material inlet 15, and the top is provided with a flue gas outlet; the overflow port 13 is connected to the semi-coke material inlet through the fourth feeder 14 through a pipeline 15.

[0032] On the synthesis gas discharge pipeline connected with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap