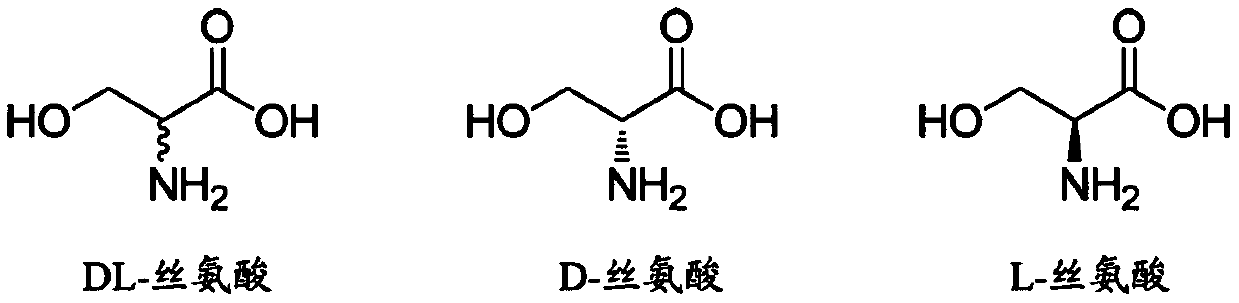

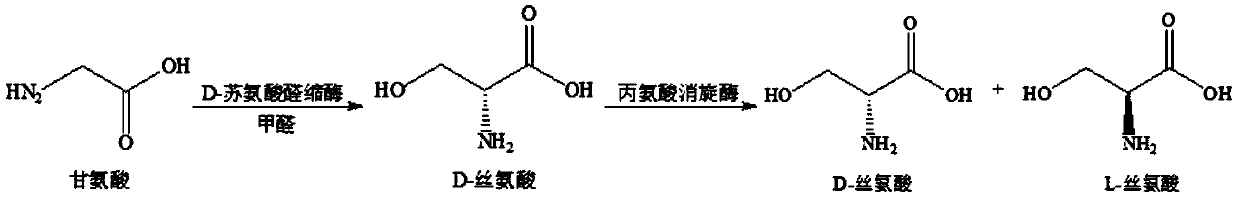

Method for preparing DL-serine by one-pot enzyme method

A technology of enzymatic preparation and serine, applied in the biological field, can solve the problems of multiple reaction steps, difficult separation, toxicity, etc., and achieve the effects of reducing the discharge of "three wastes", low production cost, and small discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

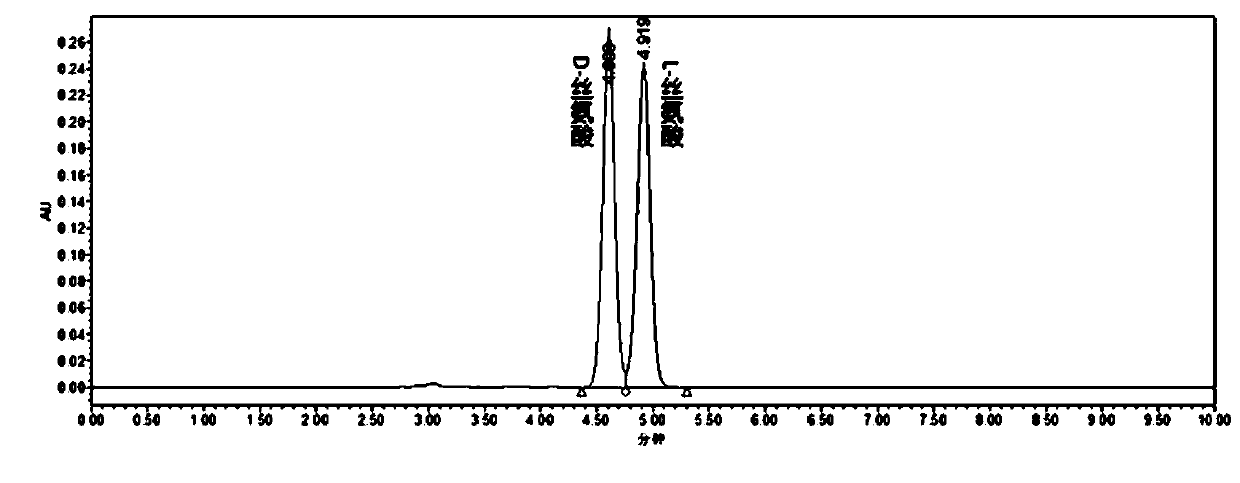

[0047] Conversion of 2.5 ton system

[0048] Add 1300L of water, 375kg of glycine, 3kg of formaldehyde solution (37%) to the reactor in turn, and control the pH at 7.0 to 8.0 with 4M sodium hydroxide solution; then add 7.5kg of magnesium chloride hexahydrate, 0.25kg of pyridoxal 5-phosphate kg, again using 4M sodium hydroxide solution to control the pH at 7.0-8.0 and the temperature at 30°C-40°C. 75 kg of recombinant D-threonine aldolase was added to start the reaction. During the reaction process, 37% formaldehyde solution was added to maintain the reaction pH between 7.0 and 8.0. After reacting for 30 minutes, add 12.5kg of recombinant alanine racemase. When the racemization equilibrium of DL-serine is detected by liquid phase, and the residual glycine is lower than 2g / L, the conversion temperature is increased to 45-50°C and the reaction is continued for 3-5 hours, and the reaction is terminated. The conversion rate is about 98%.

Embodiment 2

[0050] Transformation of 7.5 tons system

[0051] Add 3900L of water, 1125kg of glycine, 9kg of formaldehyde solution (37%) to the reaction kettle in sequence, and control the pH at 7.0 to 8.0 with 4M sodium hydroxide solution; kg, again using 4M sodium hydroxide solution to control the pH at 7.0-8.0 and the temperature at 30°C-40°C. 210 kg of recombinant D-threonine aldolase was added to start the reaction. During the reaction process, 37% formaldehyde solution was added to maintain the reaction pH between 7.0 and 8.0. After reacting for 30 minutes, add 37.5kg of recombinant alanine racemase. When the racemization equilibrium of DL-serine is detected by liquid phase, and the residual glycine is lower than 2g / L, the conversion temperature is increased to 45-50°C and the reaction is continued for 3-5 hours, and the reaction is terminated. The conversion rate is about 98.5%.

Embodiment 3

[0053] Conversion of 15 ton system

[0054] Add 7800L of water, 2250kg of glycine, and 18kg of formaldehyde solution (37%) to the reactor in sequence, and control the pH at 7.0 to 8.0 with 4M sodium hydroxide solution; then add 45kg of magnesium chloride hexahydrate and 1.5kg of pyridoxal 5-phosphate in sequence. , and again use 4M sodium hydroxide solution to control the pH at 7.0-8.0, and control the temperature at 30°C-40°C. 380 kg of recombinant D-threonine aldolase was added to start the reaction. During the reaction process, 37% formaldehyde solution was added to maintain the reaction pH between 7.0 and 8.0. After reacting for 30 minutes, add 75kg of recombinant alanine racemase. When the racemization equilibrium of DL-serine is detected by liquid phase, and the residual glycine is lower than 2g / L, the conversion temperature is increased to 45-50°C and the reaction is continued for 3-5 hours, and the reaction is terminated. The conversion rate is about 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com