Method for Improving the Safe and Stable Operation of the Pumped-Back Steam Turbine Unit System

A steam turbine unit and system safety technology, applied in the direction of safety devices, engine starting, mechanical equipment, etc., can solve the problems of threatening personal and equipment safety, polluting unit lubricating oil, high-frequency vibration of cylinder block, etc., and achieve good parameters , Improve the efficiency of power generation and the effect of stable operation of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

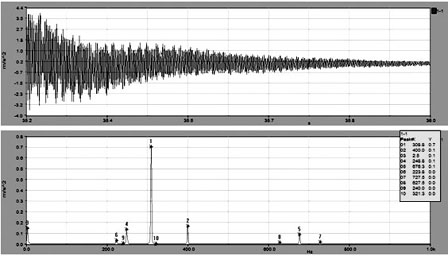

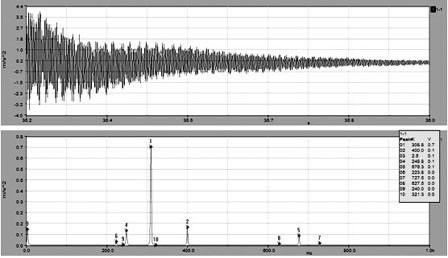

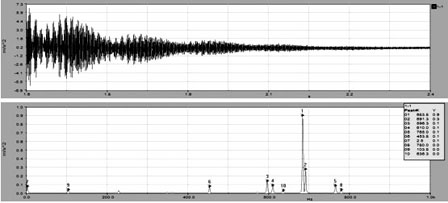

Image

Examples

Embodiment Construction

[0025] A method for improving the safe and stable operation of the pumped-back steam turbine unit system. The steam turbine cylinder of the unit system is a double-layer cylinder structure, and the high-pressure inner cylinder, high-pressure steam chamber, medium-pressure steam chamber, and two sets of partitions are installed inside the high-medium pressure outer cylinder. Plate sleeves, front and rear steam seals,

[0026] In order to realize the smooth departure of the unit, grid-connected power generation, and meet the cylinder block expansion requirements. After fully researching and discussing the design drawings of the manufacturer, without changing the structure of the existing equipment, the process adjustment of the steam seal ring was carried out to increase the expansion difference from 4mm to 6mm, reducing the start-up requirements from the technical level, and at the same time outside the cylinder body Increase the warming cylinder pipeline, and perform the warmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com