A Reverse Multi-Nozzle Solid Rocket Motor

A solid rocket, multi-nozzle technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of reducing the engine reuse rate, ablation, shell damage, etc., to improve the reuse rate, The effect of reducing the characteristic signal and reducing the replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

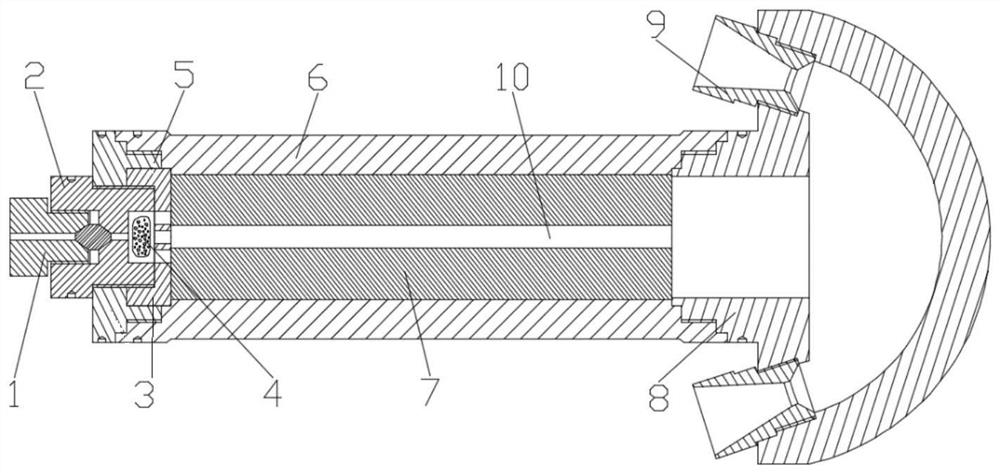

[0033] This embodiment is a reverse multi-nozzle solid rocket motor.

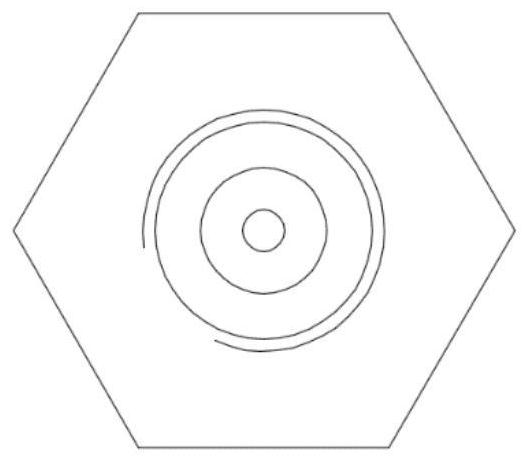

[0034] refer to Figure 1 to Figure 15 , the reverse multi-nozzle solid rocket motor of the present embodiment is composed of an ignition pressure screw 1, an ignition seat 2, a medicine retaining plate 3, an ignition medicine box 4, a front head 5, a combustion chamber casing 6, a propellant 7, and a rear end Cover 8, nozzle 9 and combustion chamber 10 form. Wherein, there are bosses at both ends of the outer circumferential surface of the combustion chamber housing 6, and the inner surfaces of both ends of the combustion chamber housing 6 are threaded surfaces; The way of threaded connection is installed on and evenly arranged on the plane of the hemispherical cavity of the rear end cover 8 through threaded connection.

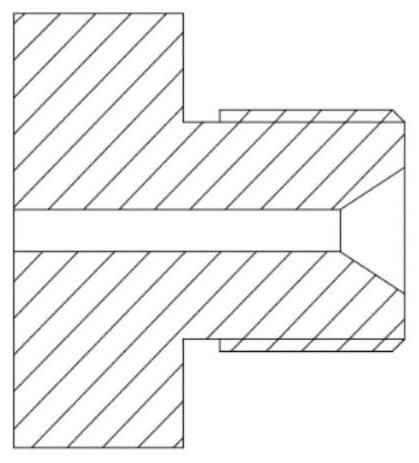

[0035] In this embodiment, the outer circumference of the front head 5 is stepped, and the inner cavity is composed of two coaxial circular holes with different diameters and the same l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com