Telescoping joint sealing structure of water turbine

A technology of sealing structure and expansion joints, which is applied in the direction of hydroelectric power generation, mechanical equipment, engine components, etc., can solve the problems of water leakage of expansion joints, changes in the compression amount of sealing strips of expansion joints, and inability to compress the sealing strips of expansion joints. The effect of water leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

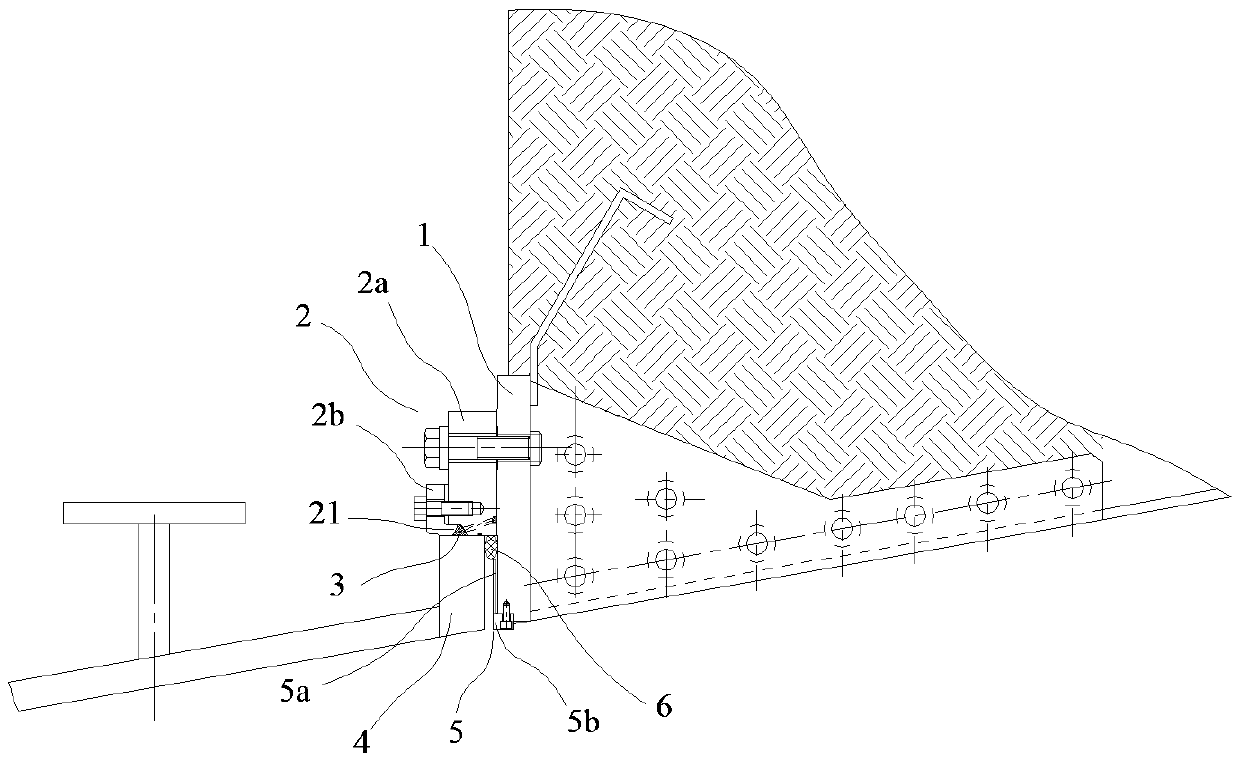

[0018] Such as figure 1 In the shown embodiment, a sealing structure of a hydraulic turbine expansion joint includes a draft tube flange 1 and a runner chamber tail flange 4, and the draft tube flange 1 and the runner chamber tail flange 4 are coaxially arranged. An expansion joint 2 is provided between the draft tube flange 1 and the tail flange 4 of the runner chamber. The expansion joint 2 includes an expansion joint pressure plate 2b and an expansion joint flange 2a. The expansion joint flange 2a and the draft tube flange 1 are fixed by bolts connect. The expansion joint pressure plate 2b is located between the expansion joint flange 2a and the rear flange 4 of the runner chamber, and the end faces of the expansion joint pressure plate 2b and the expansion joint flange 2a are fixedly connected by screws.

[0019] The inner circle of the expansion joint 2 is provided with a sealing ring 3 that is sealingly matched with the side of the flange 4 at the rear of the runner cha...

Embodiment 2

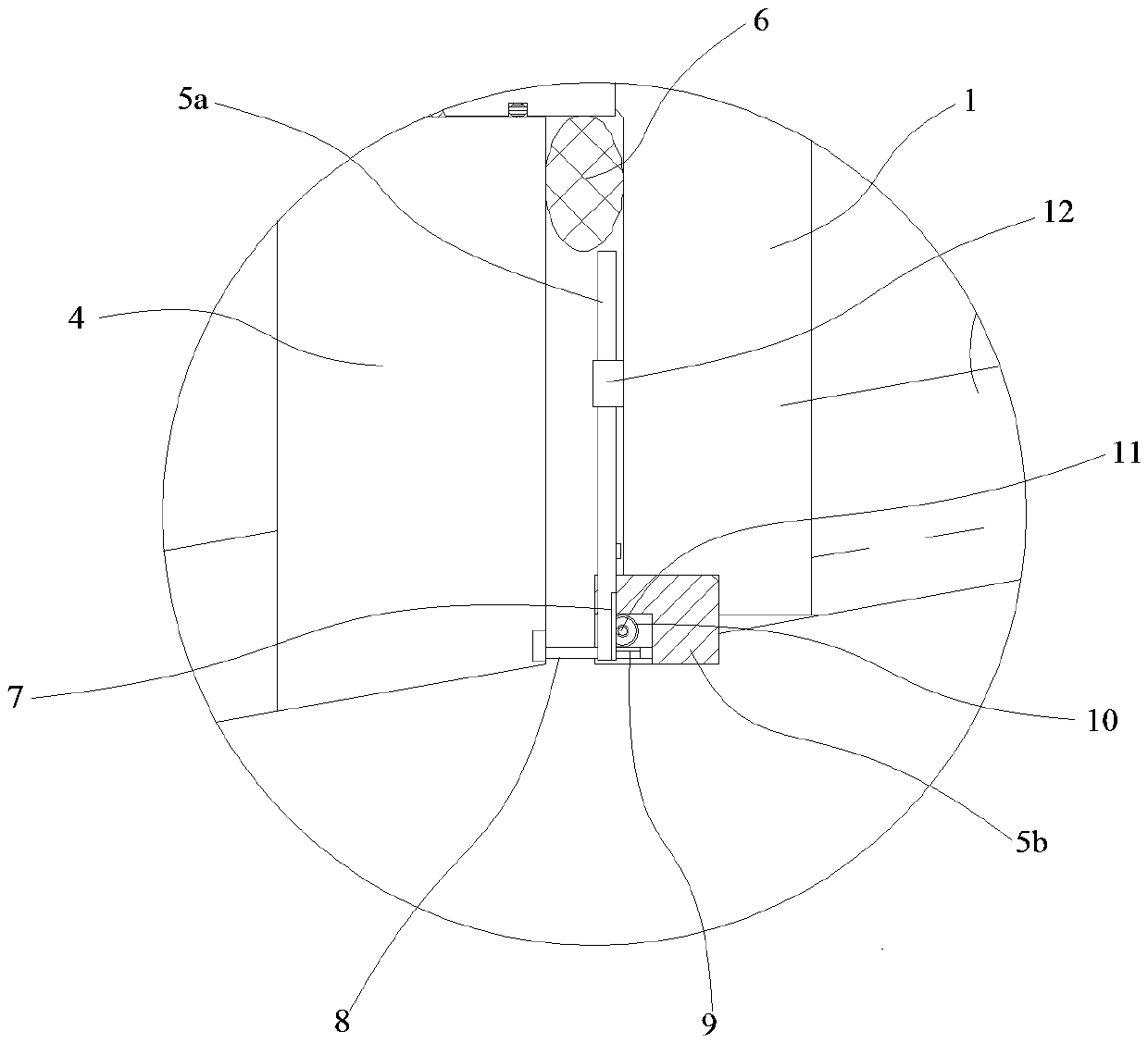

[0023] The difference between embodiment 2 and embodiment 1 is that, as figure 2 As shown, the sealing strip pressure plate 5 includes a plate body 5a and a positioning seat 5b, the plate body 5a is slidably connected with the positioning seat 5b, the positioning seat 5b is provided with a first gear 10, and the first gear 10 is provided with a coaxially fixed second gear 11. The diameter of the first gear 10 is smaller than the diameter of the second gear 11 . The plate body 5a is provided with a first rack 7 meshing with the first gear 10, the rear flange 4 of the runner chamber is provided with a rod body 8, and the rod body 8 is provided with a second rack 9 meshing with the second gear 11. 8 drives the plate body 5a to press the sealing strip 6 when it is away from the positioning seat 5b. In addition, the end surface of the draft tube flange 1 is provided with a guide block 12 slidingly fitted with the plate body 5a, and the guide block 12 guides the radial sliding of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com