A pressure self-sealing leak-proof gate valve structure

A technology for preventing leakage and gate valve, applied in the field of natural gas drilling and production equipment, can solve problems such as valve function loss, wellhead valve sealing failure, and increased wellhead safety risk, and achieve the effects of quick maintenance work, prevention of internal leakage, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

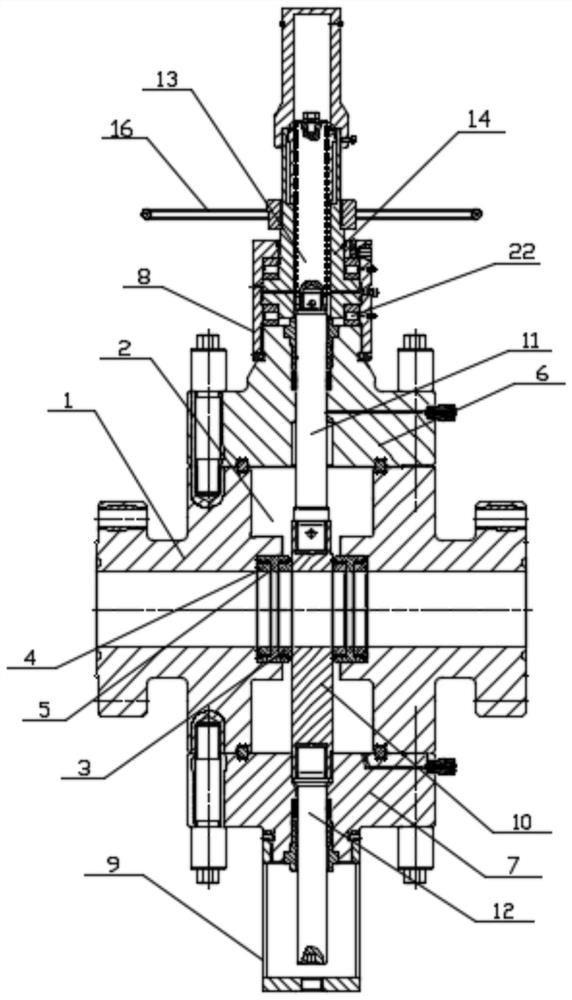

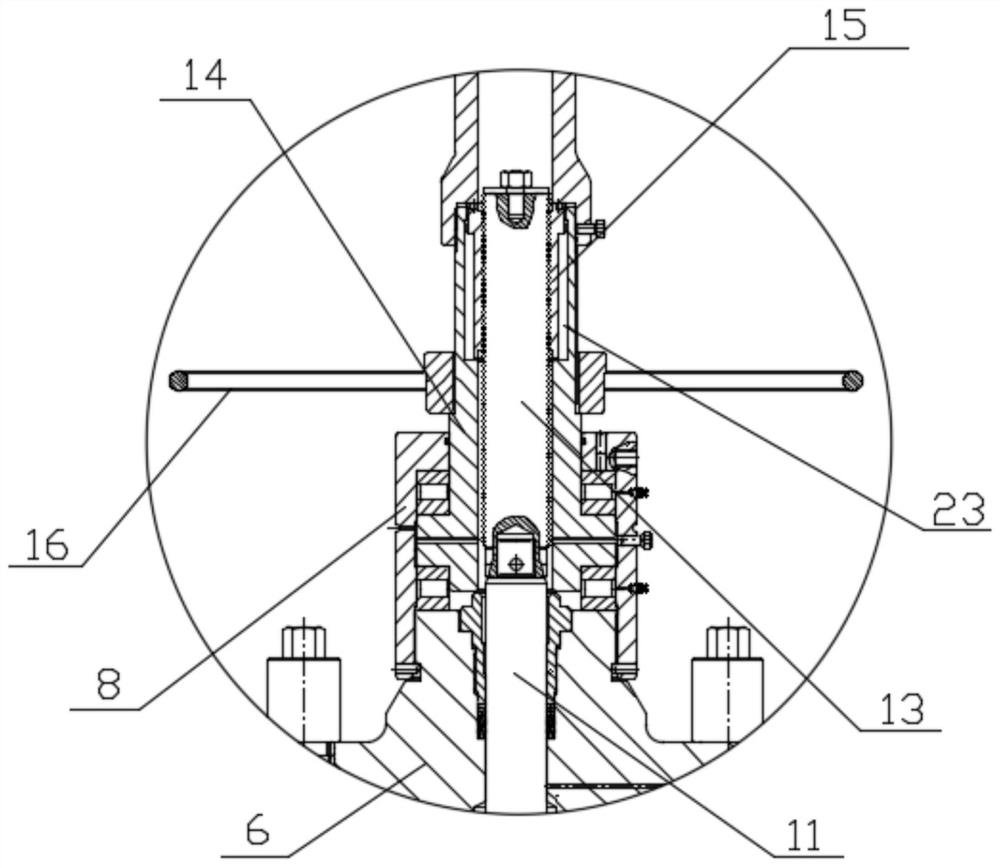

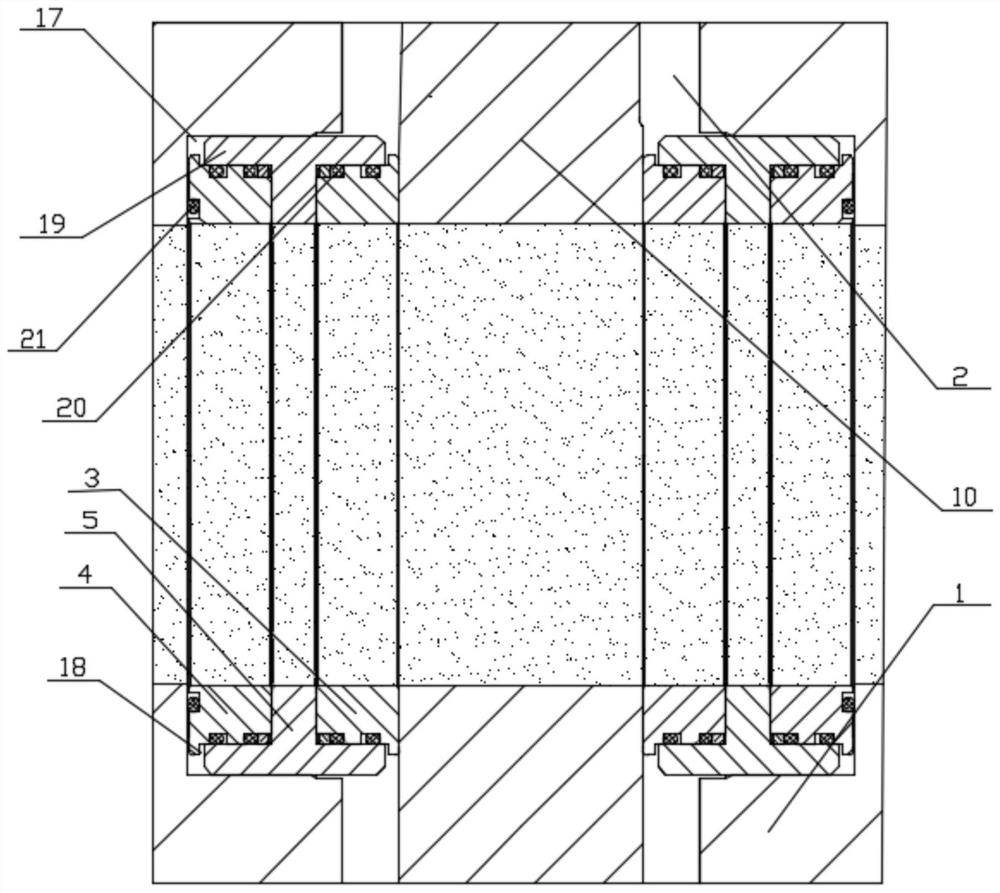

[0019] Such as Figure 1-Figure 2 As shown, a pressure self-sealing anti-leakage gate valve structure includes a valve body 1, the middle of the valve body 1 is a valve cavity 2, and the valve body 1 is sequentially provided with The rear valve seat 3 and the front valve seat 4, and a sliding sleeve 5 is arranged between the rear valve seat 3 and the front valve seat 4.

[0020] The upper and lower ends of the valve body 1 are respectively fixedly installed with an upper flange 6 and a lower flange 7, and an upper sheath 8 is fixedly installed above the upper flange 6, and the lower flange 7 A lower sheath 9 is fixedly installed below. The valve body 1 is equipped with a gate 10 in the valve cavity 2, and the upper half of the gate 10 is provided with a through hole for fluid to pass through when the valve is opened. The upper and lower ends of the gate 10 are They are respectively fixedly connected with the upper valve stem 11 and the lower valve stem 12, the upper valve st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com