Collector plate of vanadium redox battery and preparation method thereof

A liquid flow battery, vanadium oxidation technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of not particularly good mechanical properties and molding properties, low rigidity and strength of collectors, and unsmooth flow of electrolyte, etc. problems, to achieve the effect of easy sealing, high rigidity and strength, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

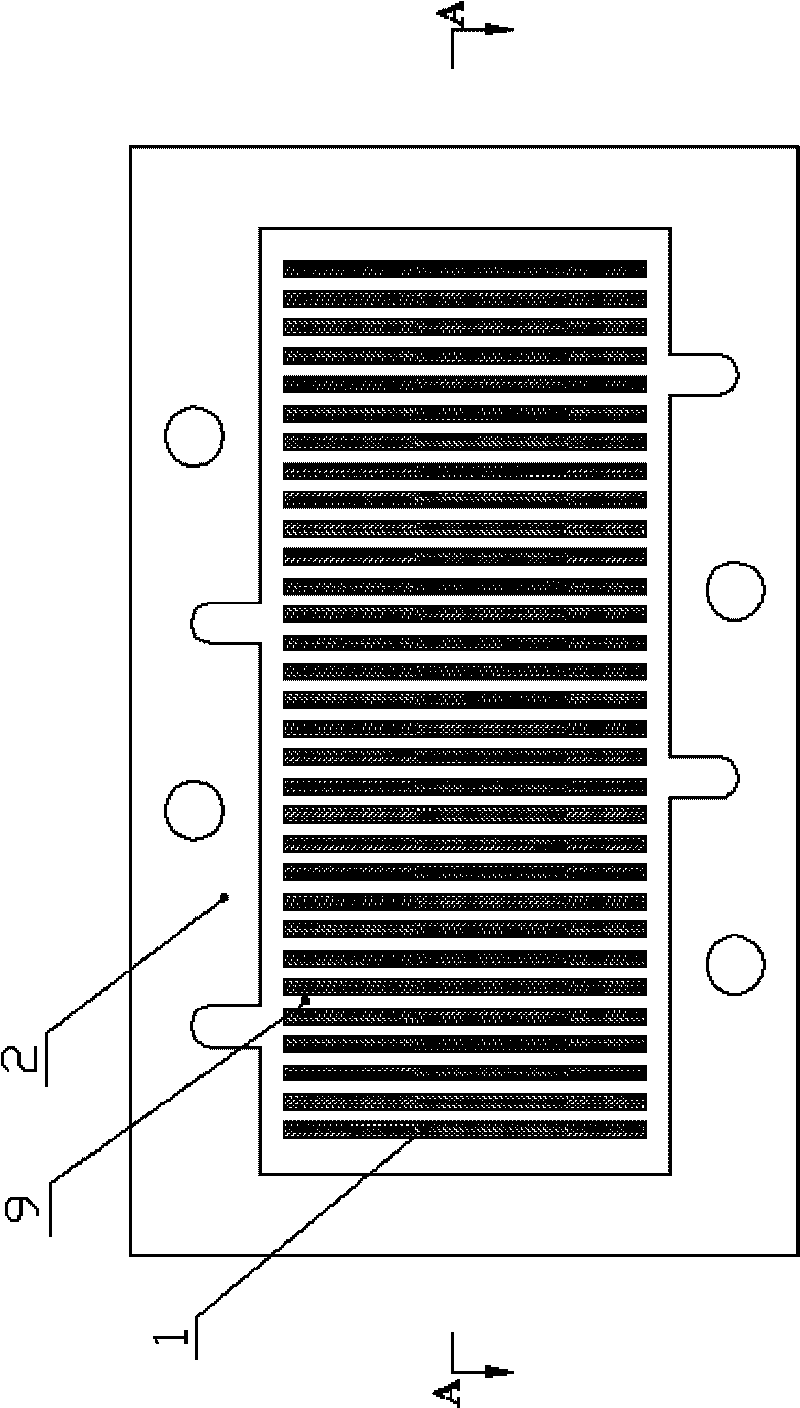

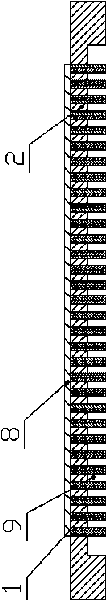

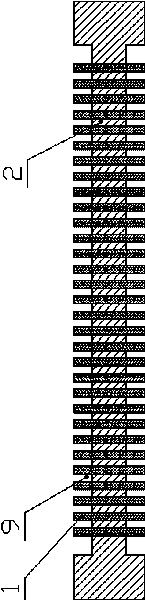

[0027] The preparation steps of the above-mentioned all-vanadium redox flow battery collector plate include: a. adding conductive fillers to thermoplastic polymers to prepare thermoplastic conductive plastic strips 1; thermoplastic polymers can be selected from polypropylene, low-density polyethylene, linear LDPE, HDPE, or thermoplastic elastomer polymers including styrene-butadiene-styrene copolymer, hydrogenated styrene-butadiene-styrene copolymer, styrene-isoprene ethylene-styrene copolymer, hydrogenated styrene-isoprene-styrene copolymer, ethylene-octene copolymer, rubber, etc.; conductive fillers can be made of conductive materials such as conductive acetylene carbon black, conductive carbon fiber, etc., and it is best to use Made of graphite.

[0028] b. Arrange and fix the conductive plastic strips 1 at intervals; when fixing, other auxiliary frames can be used to fix the conductive plastic strips 1 so that gaps are formed between adjacent conductive plastic strips 1 . ...

Embodiment 1

[0032] The conductive plastic plate after epoxy resin casting is used as the current collector, and several electrolyte flow field grooves 9 are formed on the current collector plate. The length of the conductive plastic strip 1 on the current collector plate is 130 mm, and the width is 10 mm. The liquid flow field groove 9 has a length of 130mm, a width of 3mm, and an outer edge width of the flow field of 5mm; the ratio of the ridge width to the groove width of the flow field is 1:0.3, and the ratio of the flow field groove depth to the groove width is 1:1. The current collector plate, electrode and separator were assembled into an all-vanadium redox flow battery, and the charge and discharge test was carried out. The average coulombic efficiency of 20 charge and discharge was 87.3%.

example 2

[0034] The conductive plastic plate after epoxy resin casting is used as the current collector, and several electrolyte flow field grooves 9 are formed on the current collector plate. The conductive plastic strip 1 on the current collector plate is 280mm long and 20mm wide. The liquid flow field groove 9 is 280mm long, 8mm wide, and the outer edge width of the flow field is 12mm; the ratio of the ridge width to the groove width of the flow field is 1:0.4, and the ratio of the flow field groove depth to the groove width is 1:2. The current collector plate was assembled with electrodes and separators to form an all-vanadium redox flow battery, and the charge-discharge test was carried out. The average coulombic efficiency of 20 charge-discharge cycles was 83.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com