Valve needle assembly and electronic expansion valve with valve needle assembly

An electronic expansion valve, valve needle technology, applied in the valve operation/release device, lift valve, valve details, etc., can solve the problems of reducing refrigeration efficiency, internal leakage, and failing to meet the performance requirements of electronic expansion valve, etc. Achieve the effect of reducing the driving force and balancing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

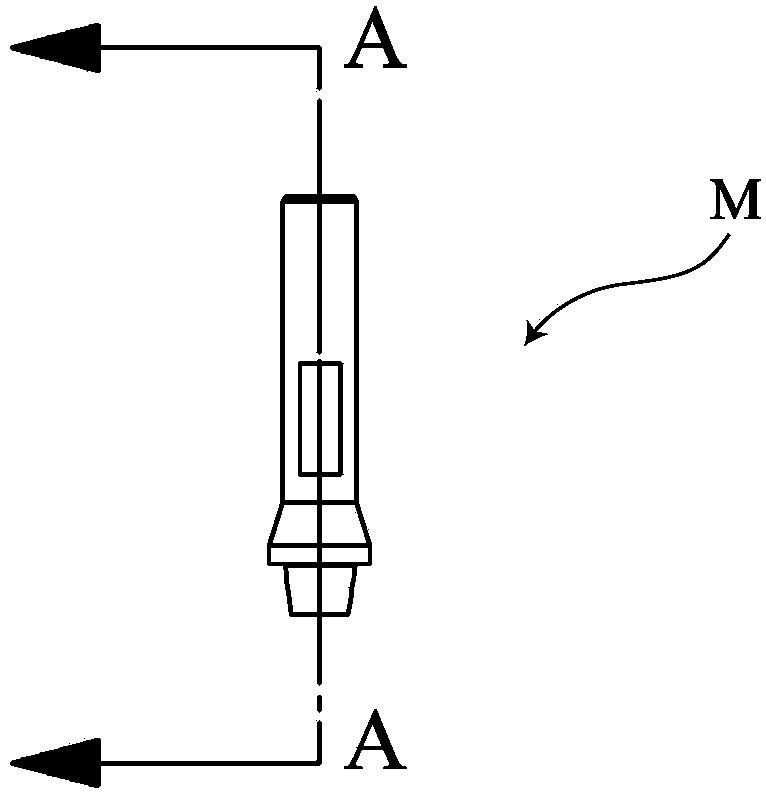

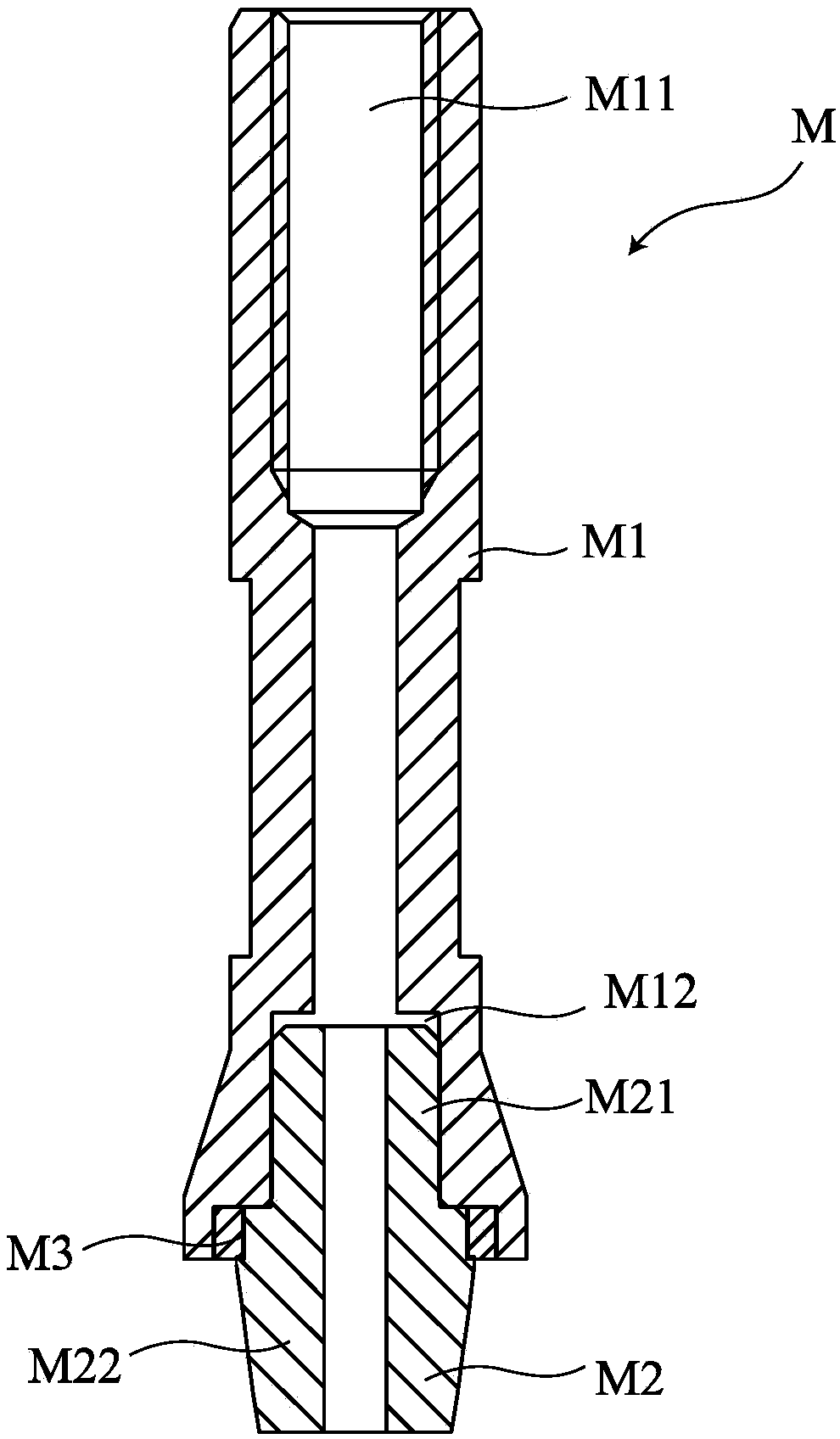

Image

Examples

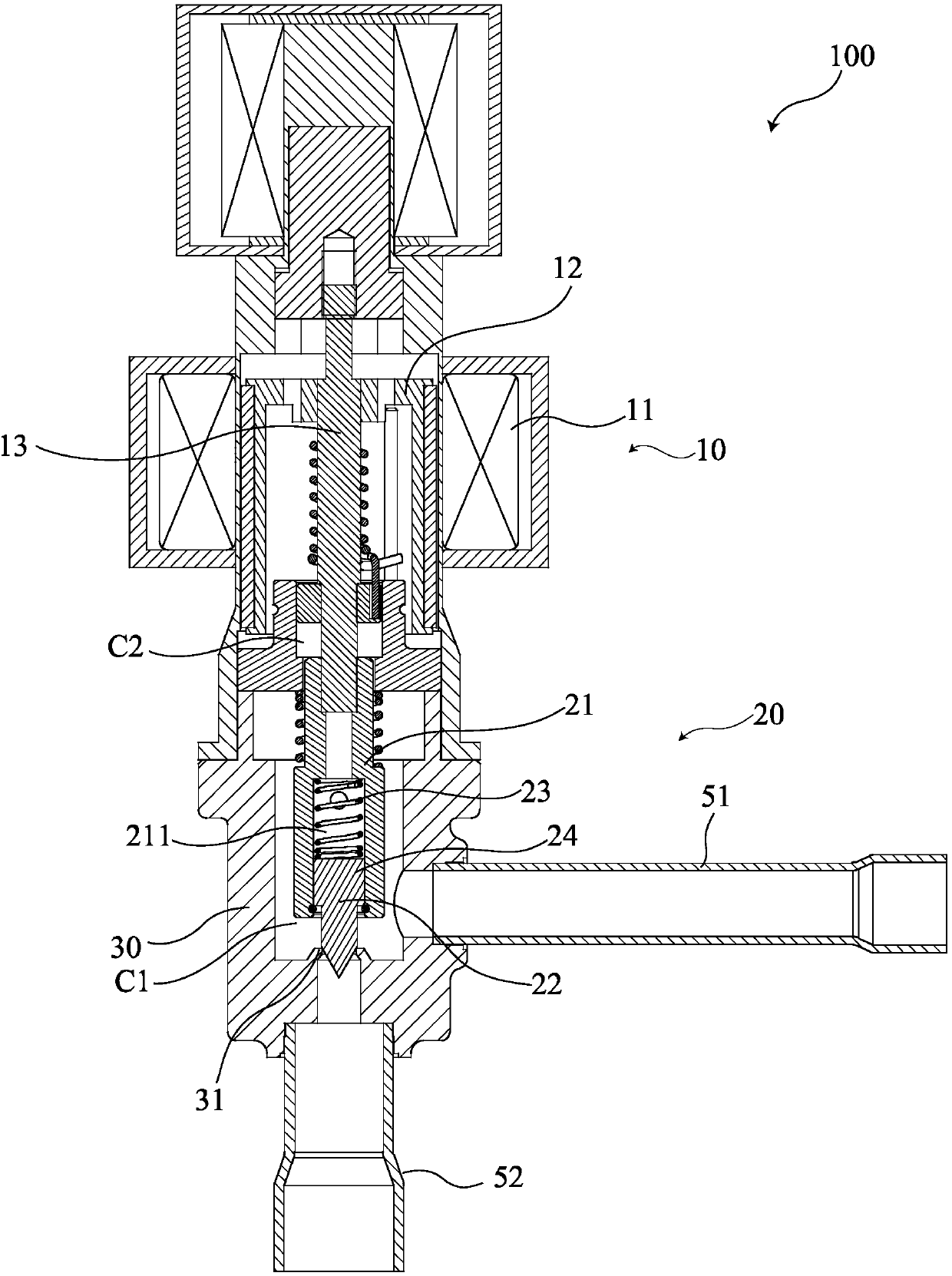

Embodiment Construction

[0040] The following description is merely exemplary in nature and is not intended to limit the invention, application and uses. It should be understood that throughout the several drawings, like reference numerals indicate the same or similar parts and features. The various drawings only schematically represent the concept and principle of the embodiments of the present invention, and do not necessarily show the specific dimensions and proportions of the various embodiments of the present invention, which may be used in specific drawings or specific parts of the drawings. Relevant details or structures of various embodiments of the present invention are illustrated in an exaggerated manner.

[0041] In the description of the embodiments of the present invention, the orientation terms related to "upper" and "lower" are used to describe the upper and lower positions of the views shown in the drawings, and the "positive direction" used ", "Reverse" is defined according to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com