Circulation heat dissipation module

A technology of circulating heat dissipation and heat source, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as poor heat exchange between gas and tube wall, and decreased circulating heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

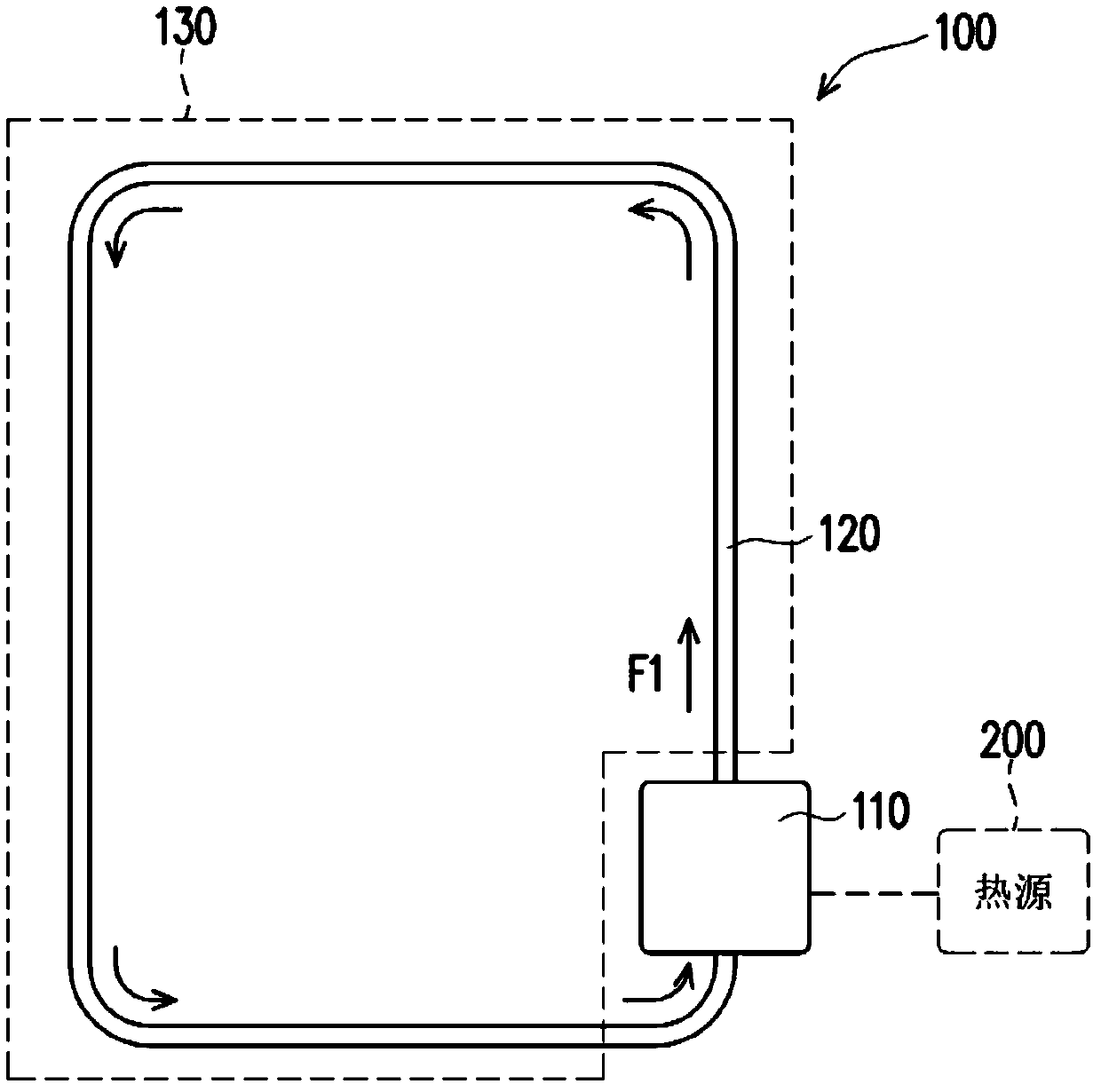

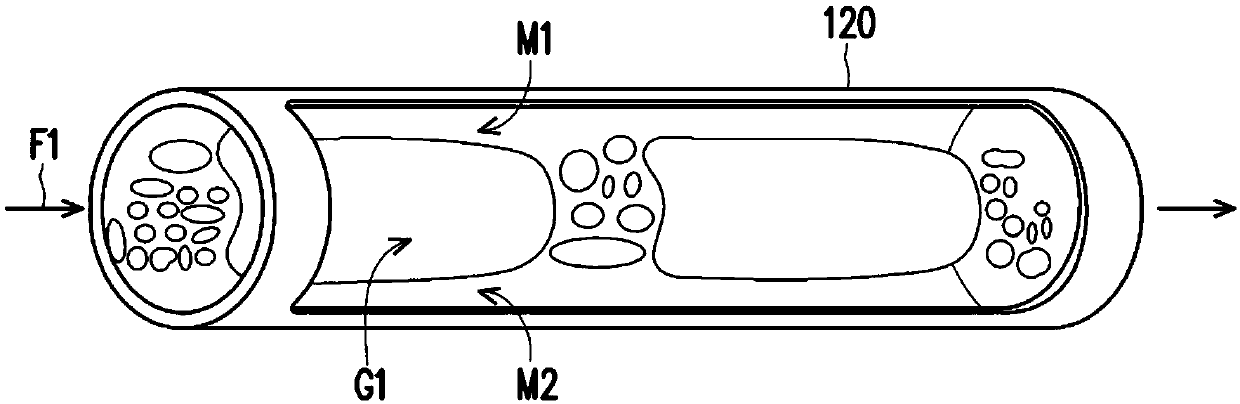

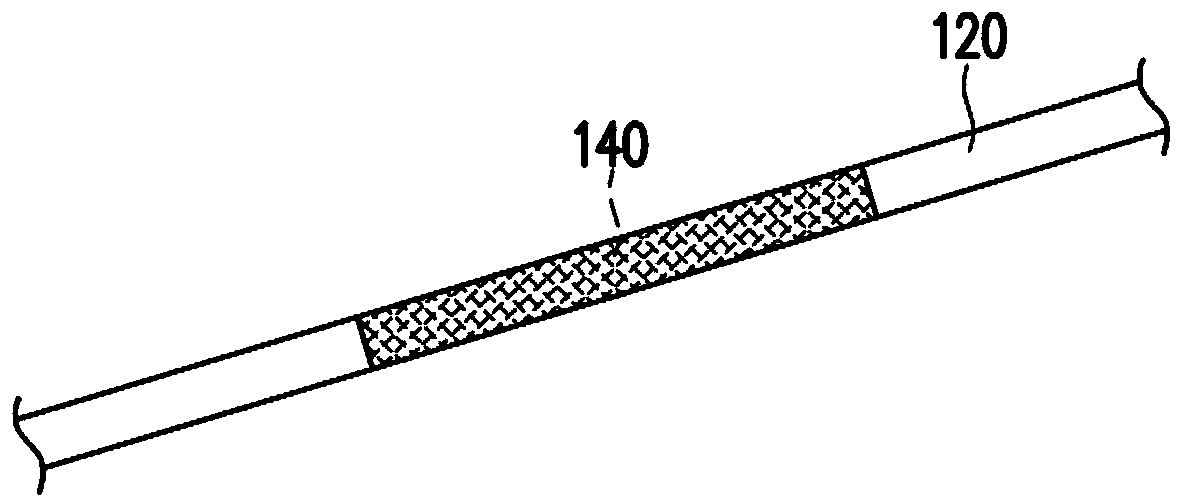

[0038] figure 1 It is a schematic diagram of a circulation cooling module according to an embodiment of the present invention. figure 2 It is the gas and liquid phase state produced when the working fluid passes through the condensation section. Please also refer to figure 1 and figure 2 , in this embodiment, the circulating heat dissipation module 100 is used to dissipate heat from the heat source 200, and the circulating heat dissipation module 100 includes an evaporator 110, a working fluid F1, and a condenser, and the condenser includes a pipe fitting 120 and a heat dissipation plate 130 that are in structural contact with each other , wherein the pipe fitting 120 is connected to the evaporator 110 to form a circuit, so that the working fluid F1 is filled in the circuit, and the liquid and gas phases are transformed by the working fluid F1 due to suction and heat dissipation, so as to achieve the effect of removing the heat generated by the heat source.

[0039] For e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com