Acoustic emission source positioning method based on multidimensional kernel density estimation

A technology of nuclear density estimation and acoustic emission source, which is used in material analysis using acoustic emission technology, processing response signals of detection, and material analysis using acoustic/ultrasonic/infrasonic waves, which can solve problems such as the impact of abnormal arrival data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

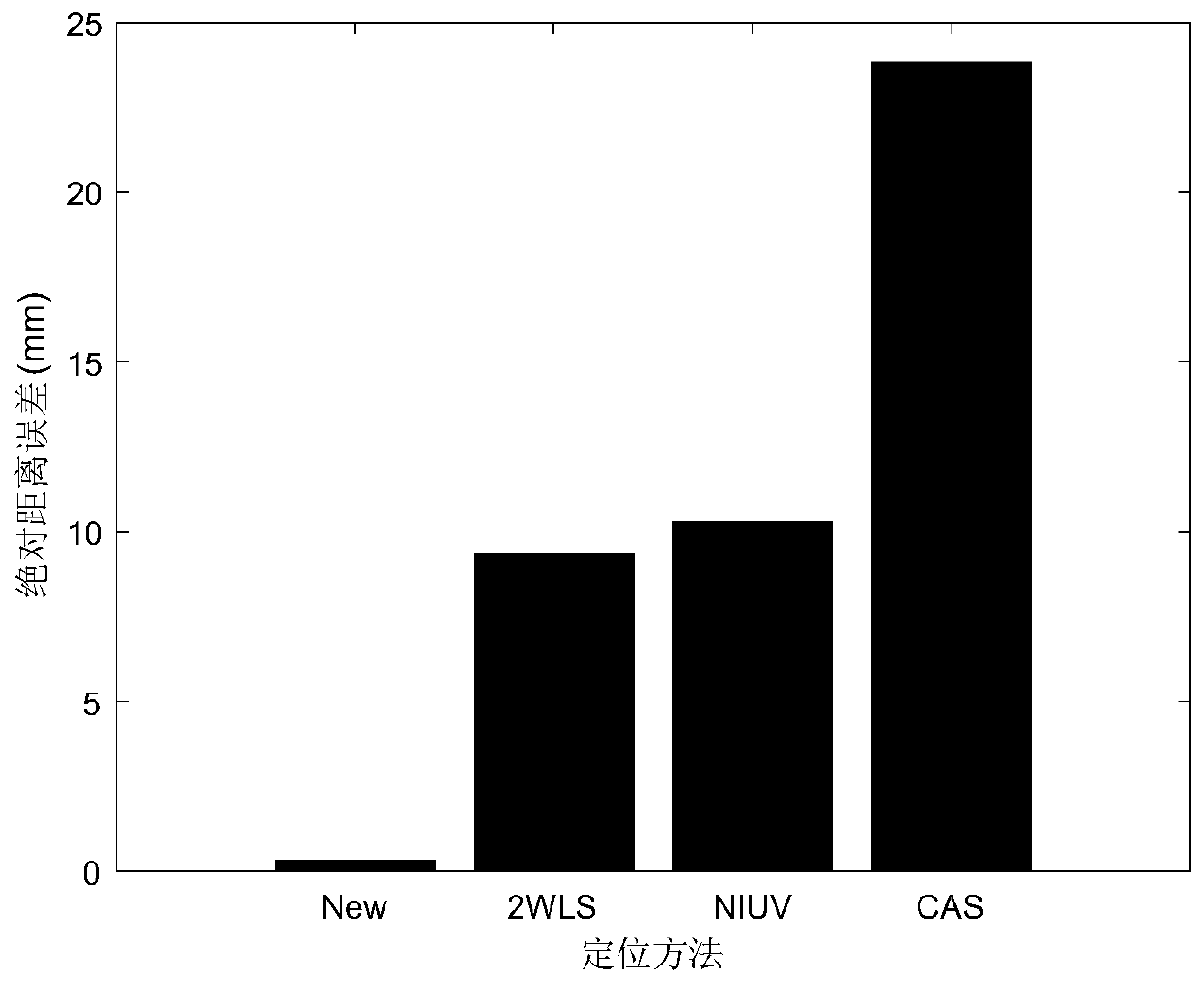

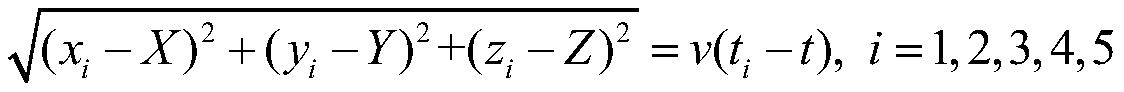

[0062] The coordinates of an acoustic emission source are preset as S(110, 160, 180), and the coordinates of the sound source are A(0,0,0), B(300,0,0), C(300,300,0), D( 0,300,0), E(0,0,300), F(300,0,300), G(300,300,300), H(0,300,300), I(300,150,150) surrounded by 9 acoustic emission sensors. The unit is mm. The wave speed is unknown. In this experiment, a set of arrival data is generated by simulation method, and an error with a variance of 0.2 μs is added to the obtained arrival data to simulate the impact of environmental noise on positioning. In addition, a large error of ±5 μs is randomly added to an arrival data , to simulate the interference of outliers. A set of arrival data generated through the above random process is: 38.38, 42.90, 40.89, 50.75, 53.10, 53.13, 55.27, 59.41, 61.55, the unit is μs.

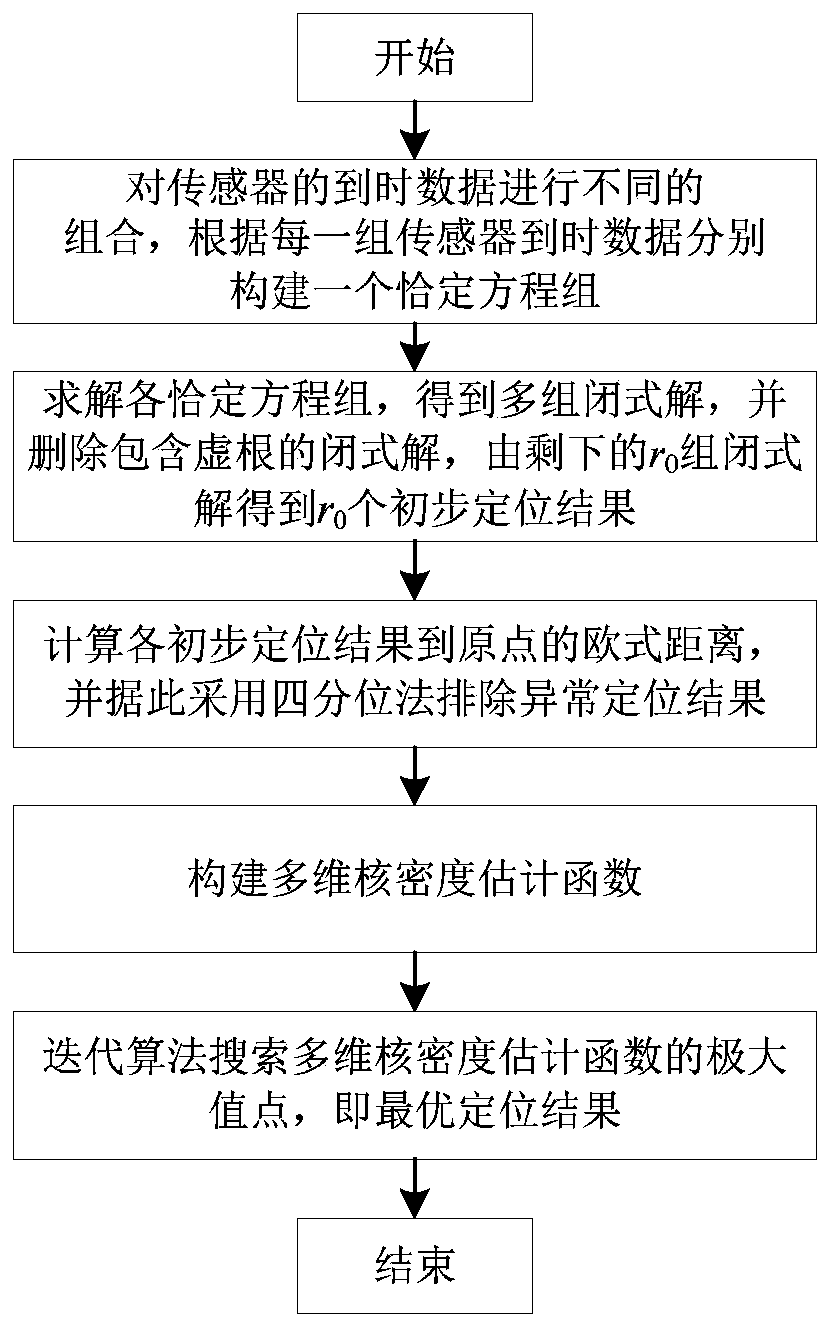

[0063] This method is described in detail with this example. For the convenience of clearly illustrating the problem, be divided into the following five steps and set f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com