Secondary optimization control method for firing process of rotary cement kiln

A cement rotary kiln, secondary optimization technology, applied in program control, electrical program control, comprehensive factory control, etc., can solve problems such as the probability of control system failure, the decline of cement clinker quality, and the failure of kiln head coal injection valve, etc. Achieve the effect of flexible adjustment, improved system fault tolerance, and improved impact of faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Take the firing process of cement rotary kiln as an example:

[0049] In the cement production process, the cement rotary kiln firing process is an important part of cement production. After the cement raw meal is prepared, the cement raw meal continues to enter the cement rotary kiln. At this time, the coal injection kiln head of the rotary kiln starts to inject coal into the rotary kiln. The rotary kiln is heated, and the cement clinker reacts. Rising to a certain level, the cement raw meal is gradually transformed into cement clinker.

[0050] Step 1. Establish a single-input and single-output model of the cement rotary kiln firing process. The specific steps are:

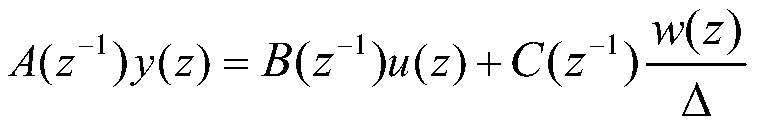

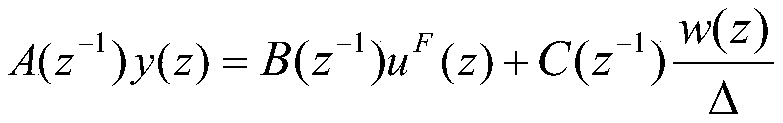

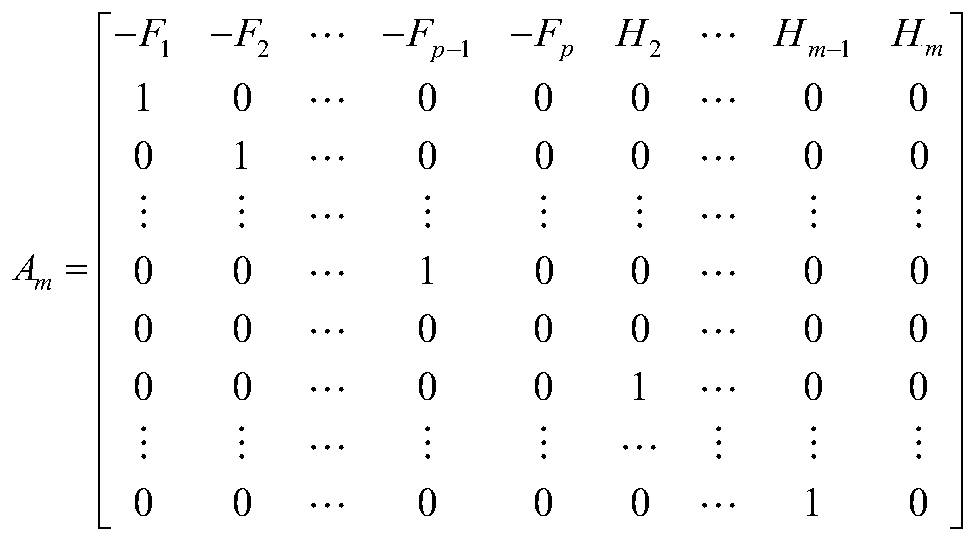

[0051] 1-1. First collect the real-time operation data of the cement rotary kiln firing process, and establish a cement rotary kiln firing process system model. The firing process of cement rotary kiln under variable disturbance is described as the following form:

[0052]

[0053] Among them, k repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com