Tire zero point positioning method

A zero-point positioning and tire technology, which is applied in automobile tire testing, computer components, electromagnetic radiation induction, etc., can solve problems such as complex control, high system cost, and small detection range of color difference sensors, and achieves a large scanning field of view and simple control methods , The effect of simplifying the hardware structure and operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

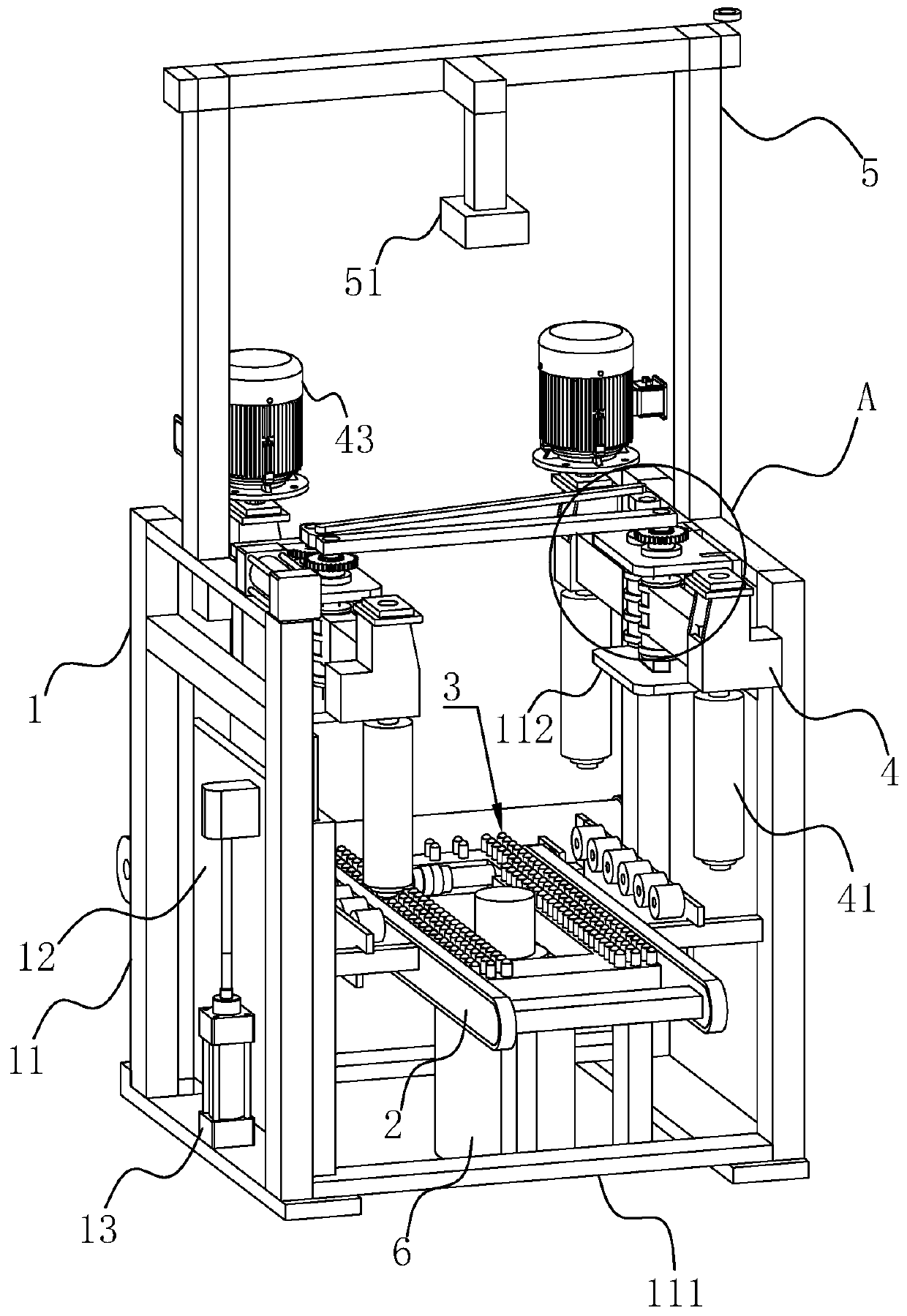

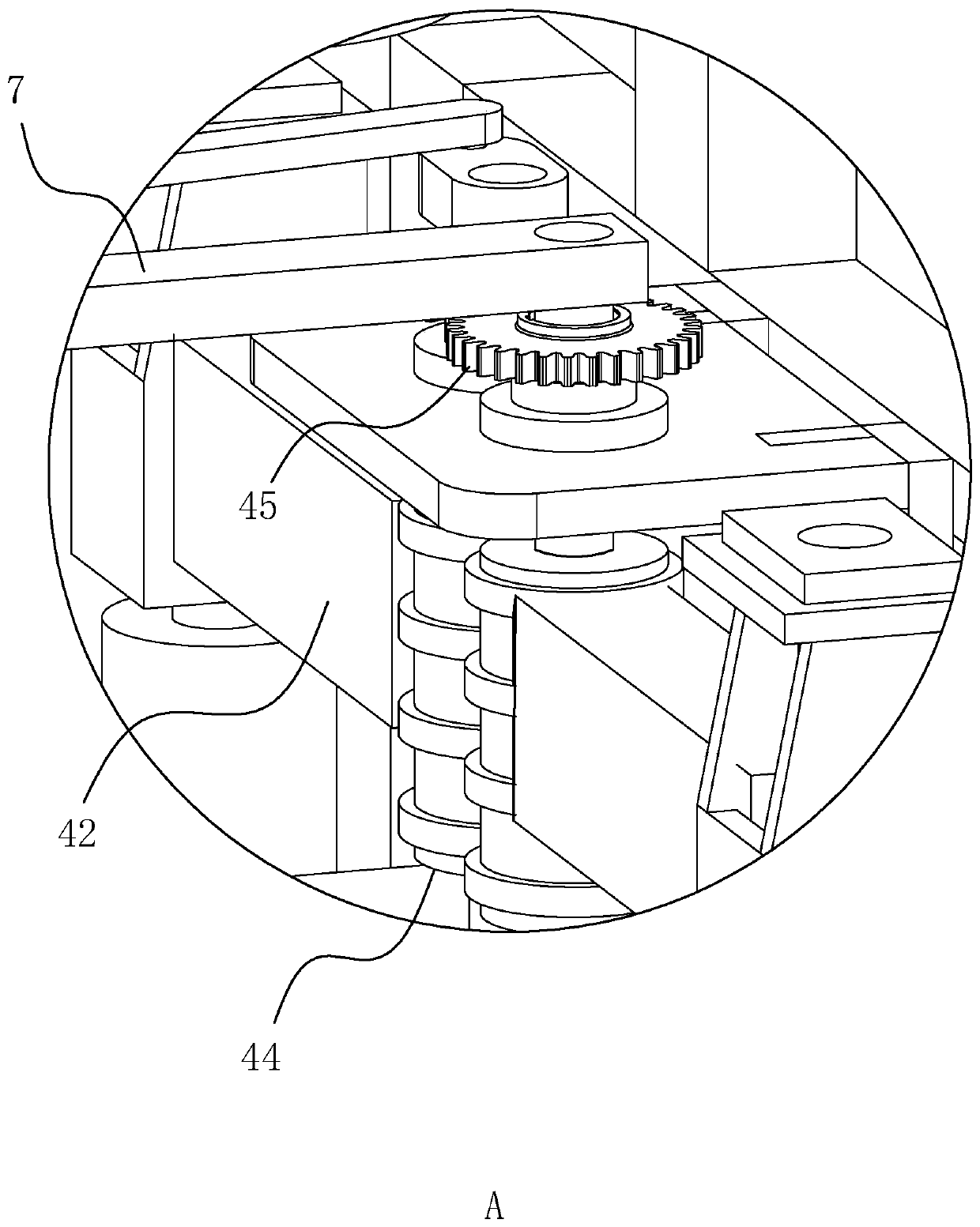

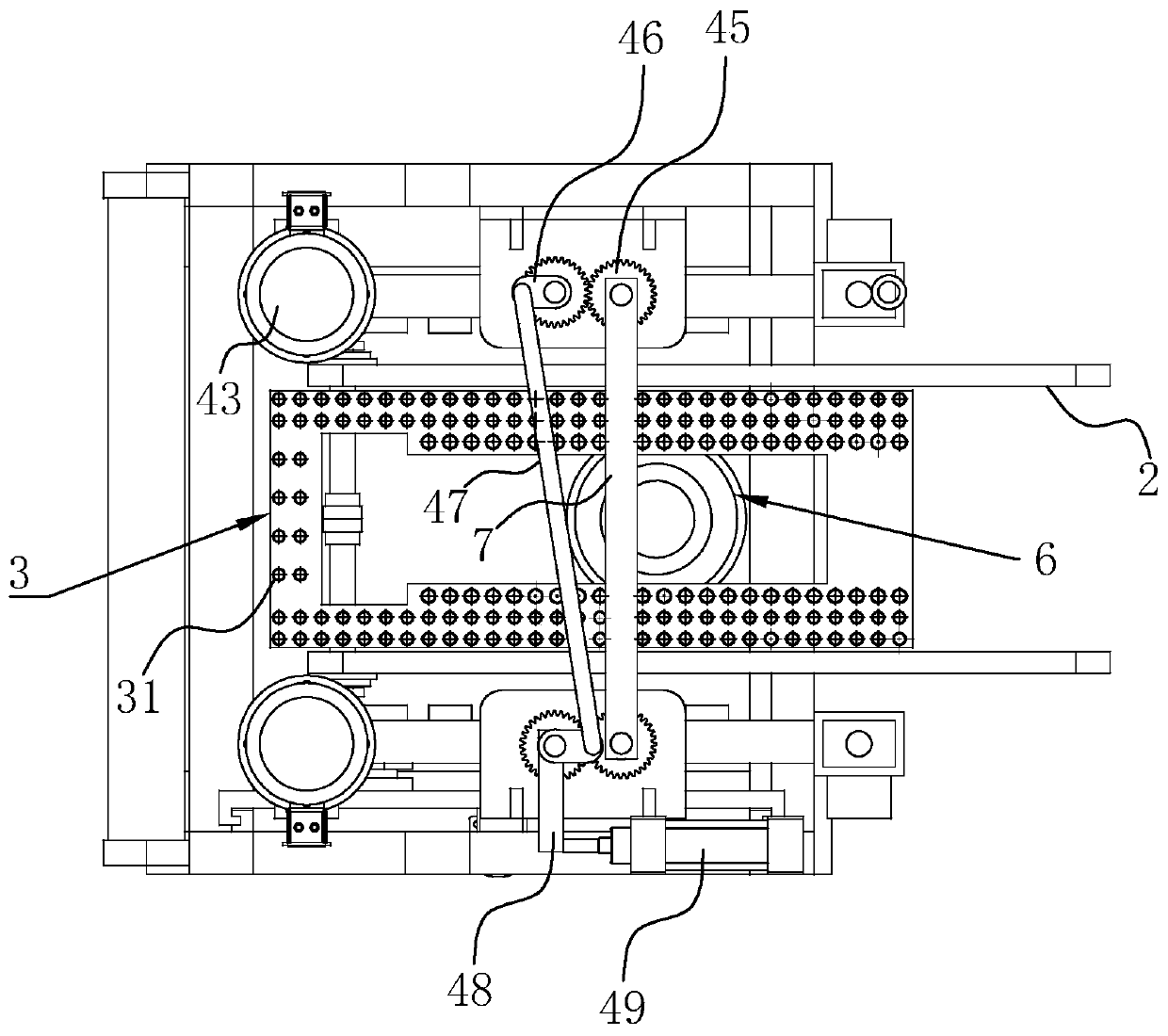

[0041] refer to figure 1 , is a tire zero point positioning device disclosed in this embodiment, including a main body frame 1, two conveyor belts 2 located between the main frame 1, a lifting drive device for driving the conveyor belt 2 to move vertically, and a lifting drive device located between the two conveyor belts 2 The inner rotary table 3, the lifting brake device 6 located at the center of the rotary table 3, the positioning sensor 51 located above the conveyor belt 2, and the controller cooperating with the positioning sensor 51, two arms are arranged on the outer sides of the two conveyor belts 2 respectively. 4. After the tire is placed on the conveyor belt 2, the tire is moved directly above the lifting brake device 6 through the conveyor belt 2, and the tire position is fixed by the lifting brake device 6 and four arms 4, and the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com