Supply-Hub-based supplier management inventory operation method

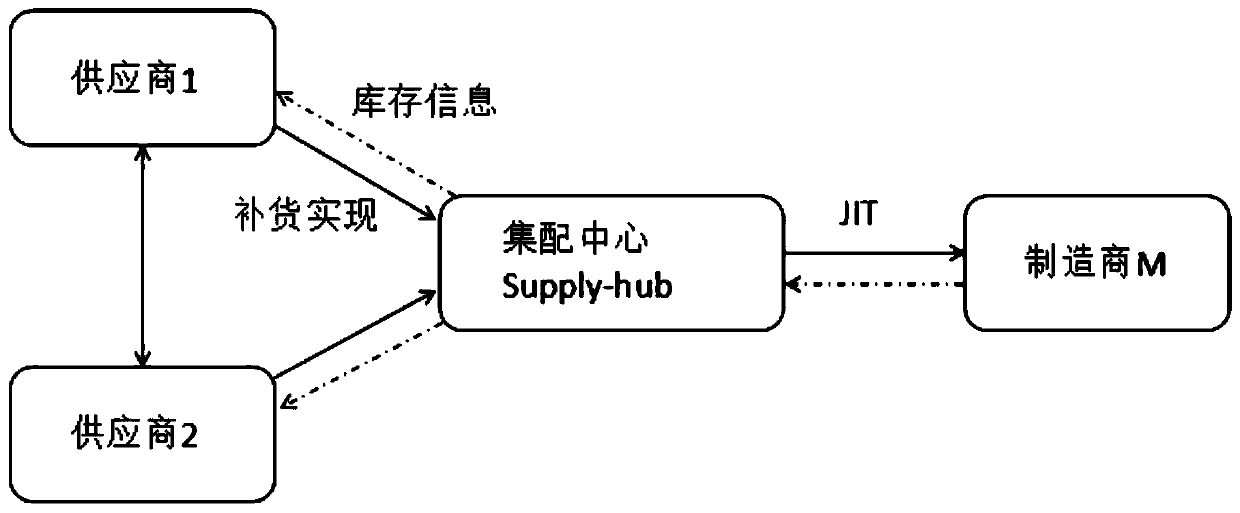

A supplier and inventory technology, applied in the field of supplier management inventory operation based on Supply-Hub, can solve the problems of not considering the VMI supply chain model, and the lack of research on the VMI pricing model, so as to reduce operating costs and transportation costs, and reduce inventory Cost, the effect of reducing white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

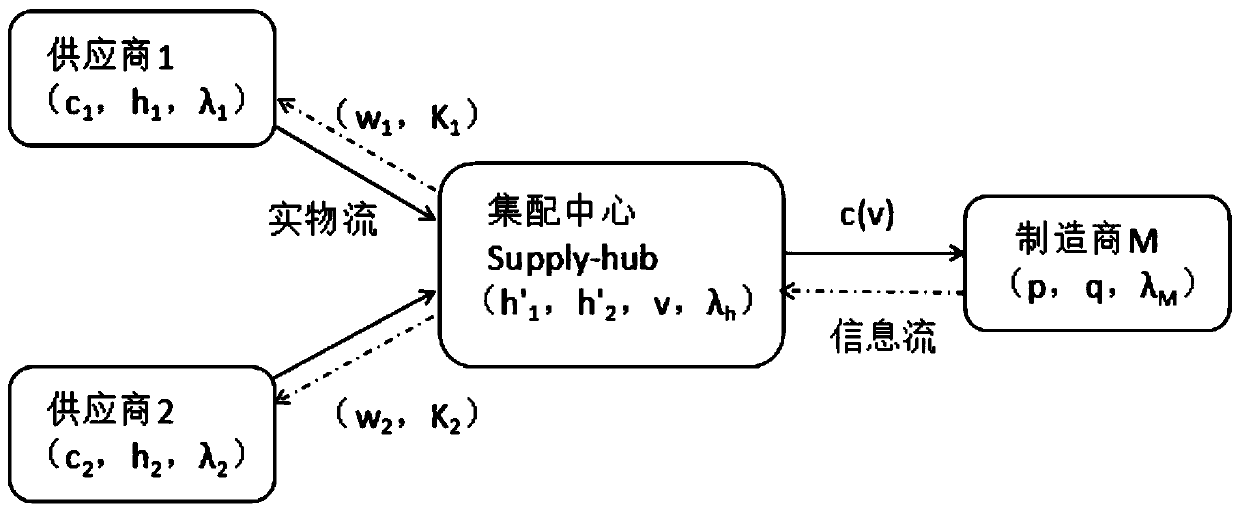

[0045] Centralized pricing decision model

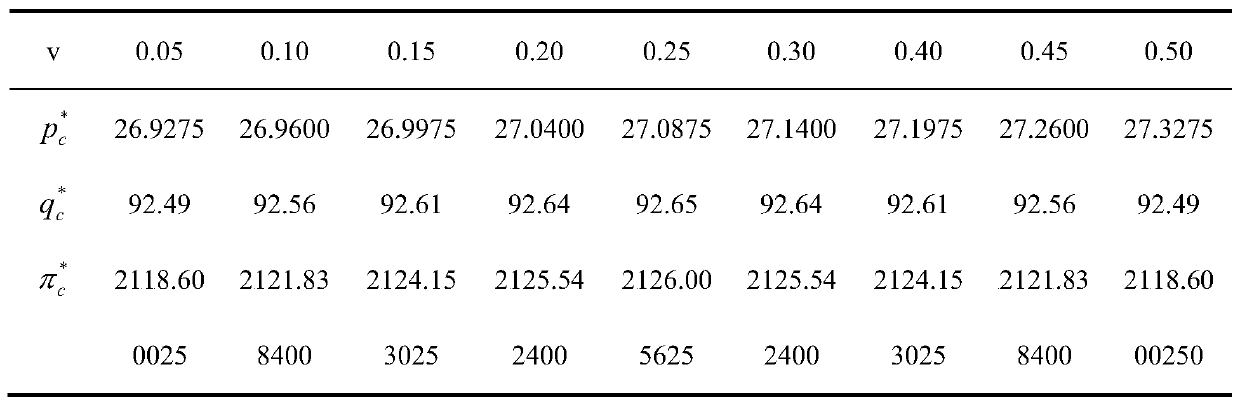

[0046] Since hi and h’i are the annual inventory holding cost per unit of the supplier and the distribution center / 2, the inventory cost of the unit q is (2hi)q / 2=hiq. Let Hi=hi+h’i, then Hi is the total inventory holding cost of component i. In the Supply-hub-based VMI supply chain, the total cost borne by supplier i ci=(ci+hi)q+Ki; the cost borne by the manufacturer is the service cost of the distribution center c(v)=βv2 . The actual market demand d=a-mp, and the demand function q=d+nv=a-mp+nv sent by the manufacturer to the distribution center under the influence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com