Anomaly detection method for rail fasteners with automatic sample labeling

An automatic labeling and anomaly detection technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as poor promotion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

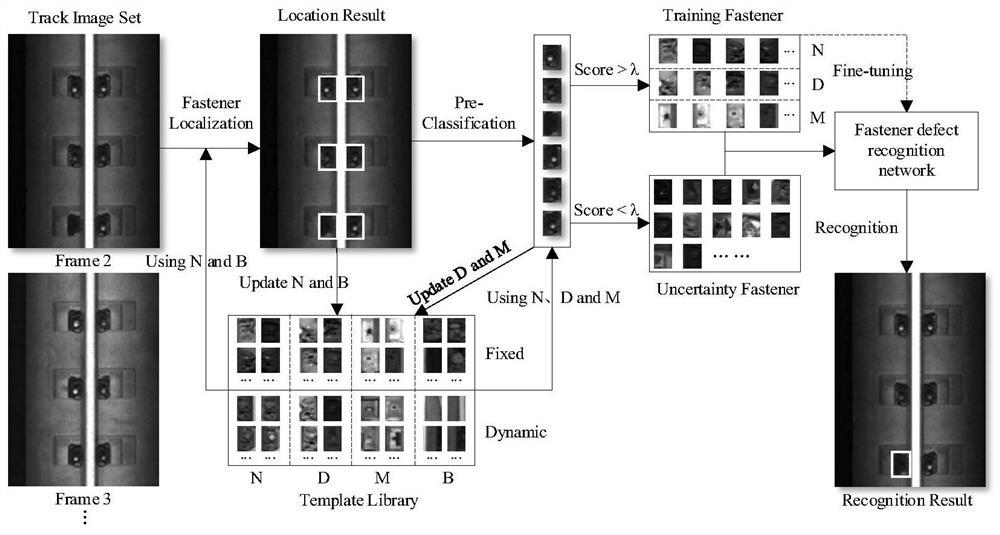

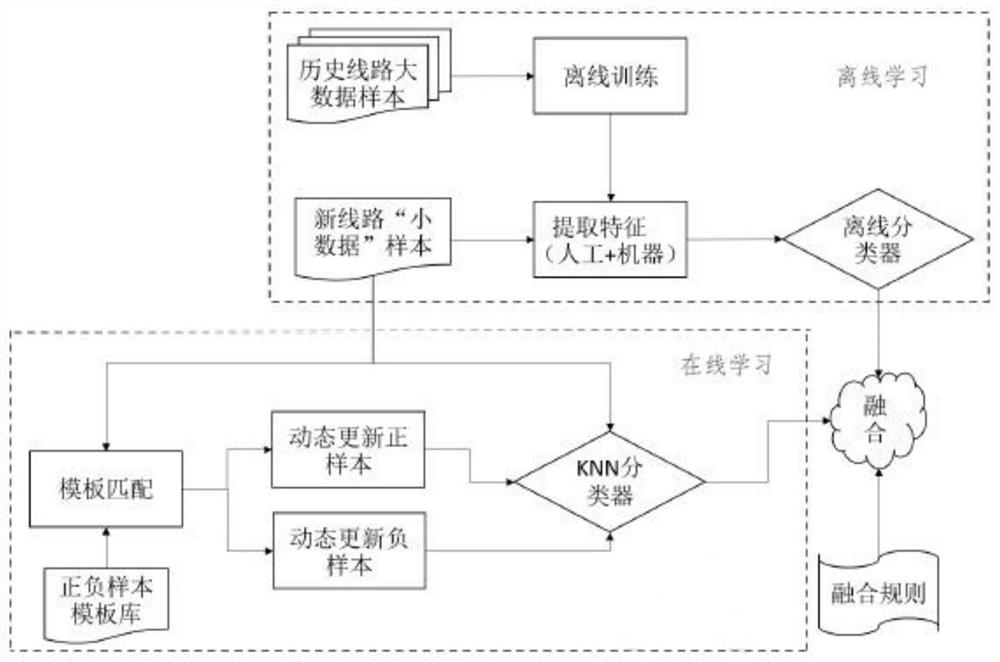

[0063] Such as figure 1 As shown, a method for detecting abnormalities of rail fasteners automatically marked by a sample of the present invention comprises the following steps:

[0064] Step 1, collecting orbital images;

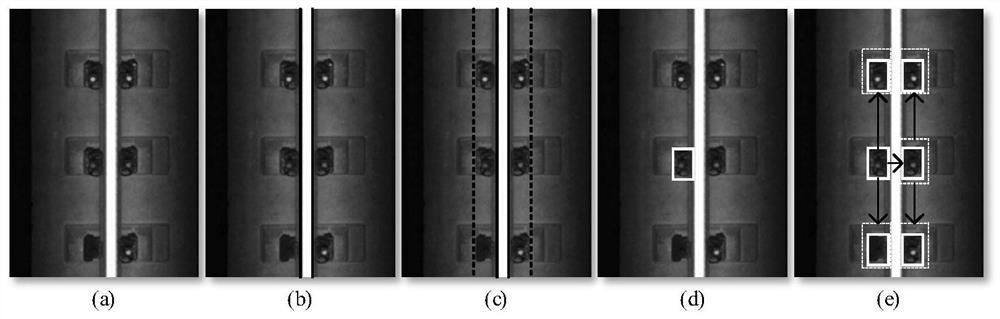

[0065] Step 2, set up a template library, said template library includes a fixed part and a dynamic part; at first existing fastener area templates and background area templates are added to the fixed part in the template library; for a railway line to be detected, the user needs to manually Locate the fastener region in the first frame of the track image and store it into a fixed section in the template library;

[0066] Classify the templates of the fastener area according to categories, and divide them into normal fastener templates-N and defective fastener templates, and classify the defective fastener templates according to categori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com