Hook type commutator copper

A commutator and hook-type technology, applied in the direction of current collectors, rotary current collectors, electrical components, etc., can solve the problems of increased tool wear, large milling workload of milling cutters, and long length of bakelite powder hanging material, etc. To achieve the effect of reducing workload, reducing tool wear and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

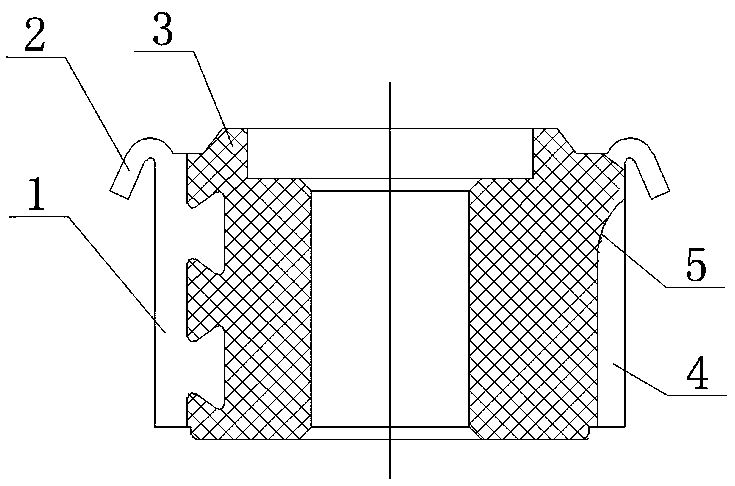

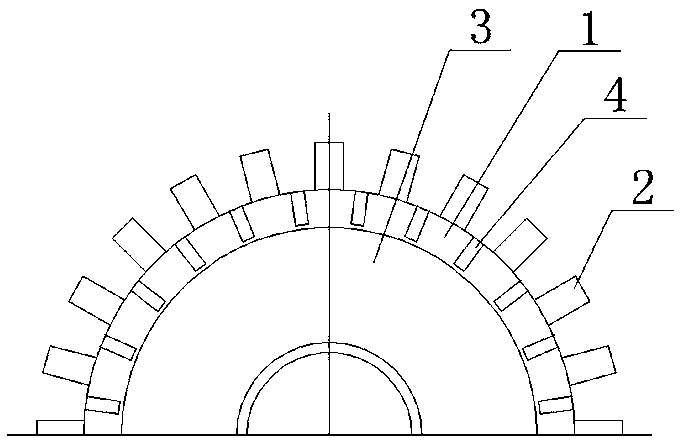

[0018] Such as figure 1 , 2 As shown, the hook-shaped commutator made of the copper sheet of the hook-shaped commutator of the present invention is composed of a bakelite powder matrix 3 and twenty-four pieces of commutators arranged in a circle on the outer circle of the bakelite powder matrix 3 Composed of copper sheets 1, the top of the reversing copper sheet 1 is provided with a hook 2, the reversing copper sheet 1 and the bakelite powder matrix 3 are integrally injection molded, and the adjacent reversing copper sheets 1 are milled out with a disc milling cutter for insulation The slot 4 is used for inter-chip insulation, and the top of the insulating slot 4 passes through a circular arc transition 5 without being milled through.

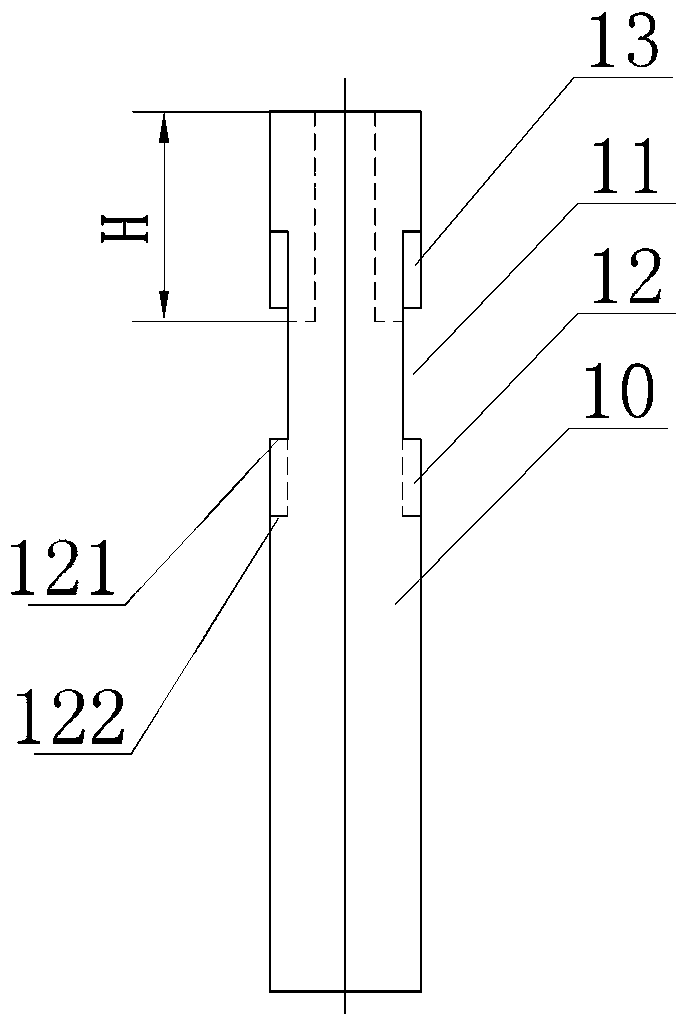

[0019] Such as Figure 3-5 As shown, the hook-type commutator copper sheet of the present invention has a bar-shaped body 10, the outer surface of the bar-shaped body 10 is a circular arc surface, and the inner surface is provided with two up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com