Stepping linear motor with hollow shaft

A linear motor, hollow shaft technology, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve the problems of cumbersome, low versatility, and difficult process, achieve good versatility, avoid process complexity, and strong flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution in the embodiment of the present invention will be clearly and completely described below, obviously, the described embodiment is a module embodiment of the present invention, not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

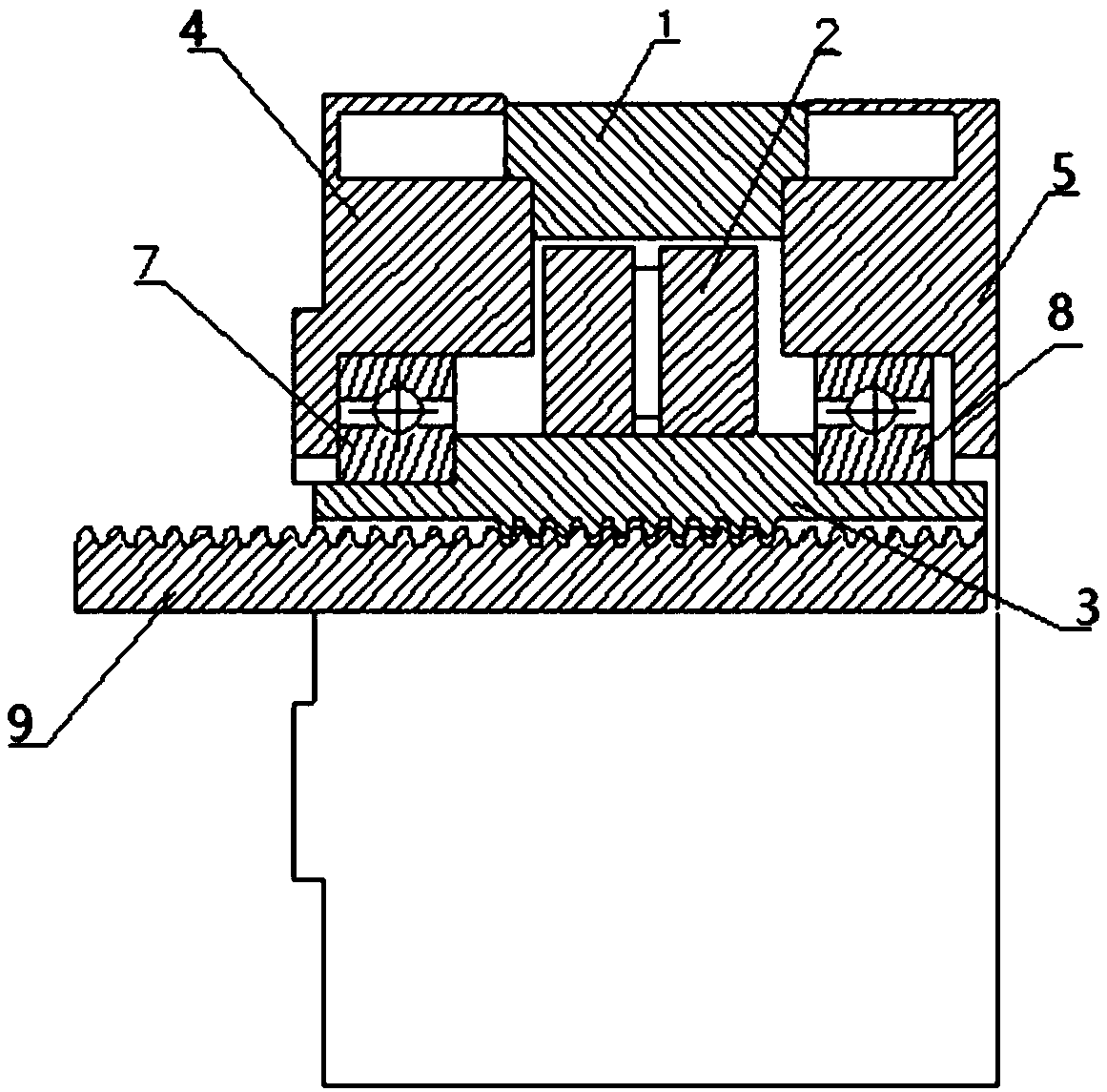

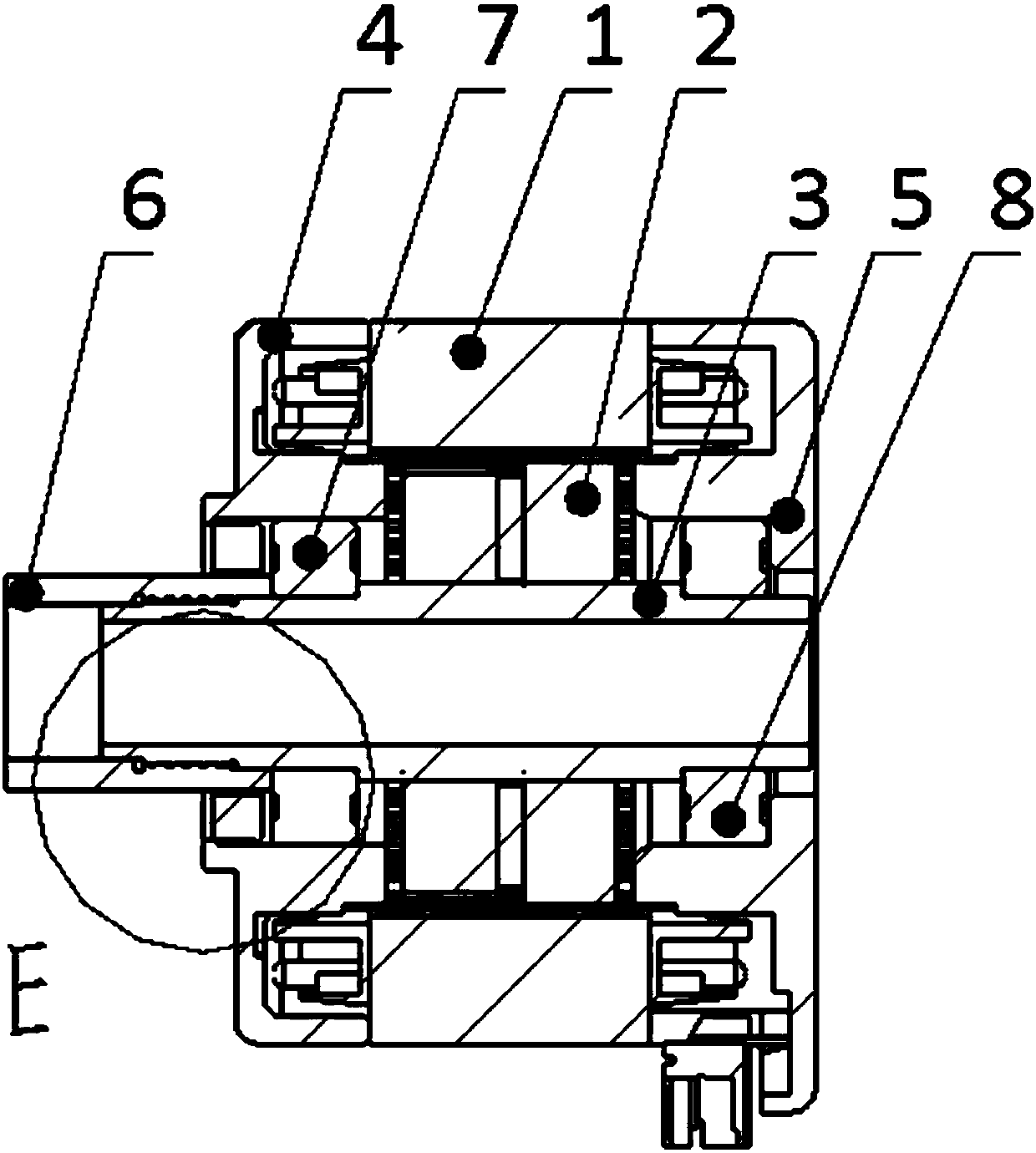

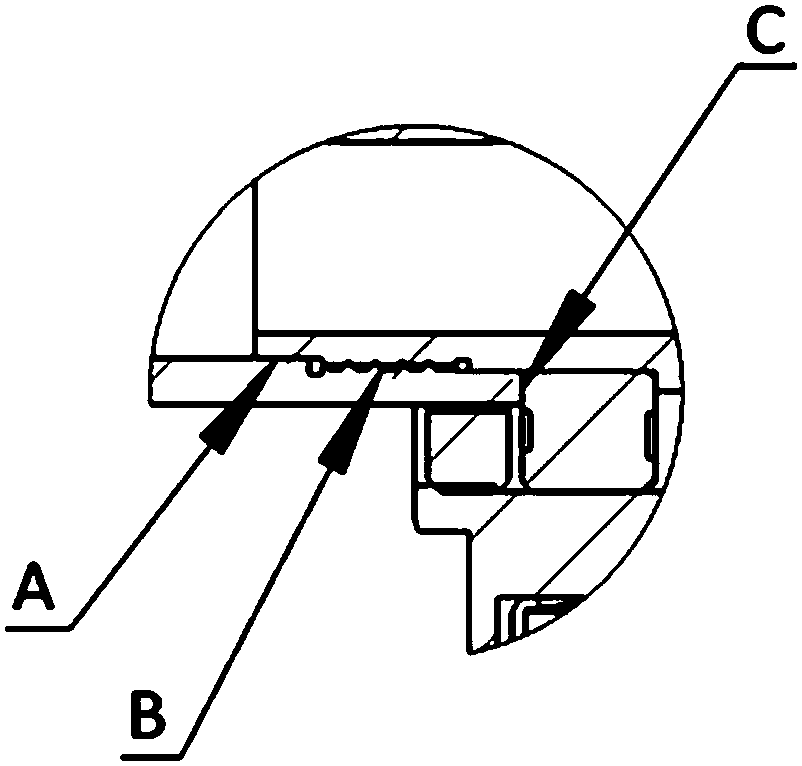

[0027] Such as figure 2 As shown, a stepping linear motor with a hollow shaft includes a stator 1, a rotor 2, a rotor shaft 3, a front end cover 4, a rear end cover 5, a front bearing 7, a rear bearing 8, and external connectors 6 or nuts, The external connecting piece 6 or the nut is connected to the rotor shaft 3, and when the motor rotates, the external connecting piece 6 or the nut is driven to move linearly. Concentric concentric mating surface A, the external connector 6 is closely connected with the rotor shaft 3 through the thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap