Electronic atomization device, and atomizer and heating assembly thereof

A technology of heating components and nebulizers, which is applied in nebulizers for treatment, inhalers, tobacco, etc., which can solve problems such as poor user experience, easy liquid leakage, and electronic components contaminated by smoke liquid, so as to improve user experience. Experience and avoid the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

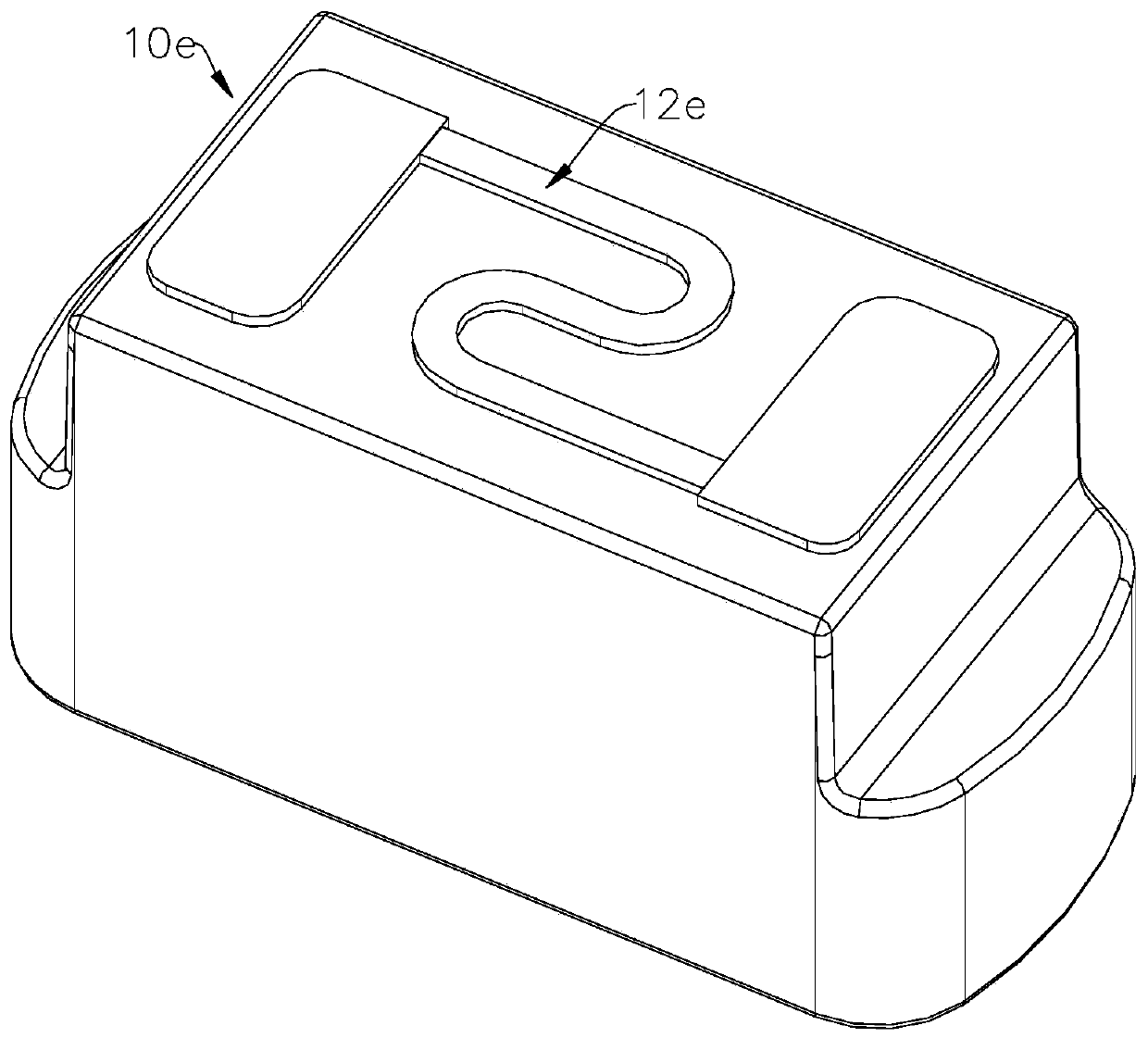

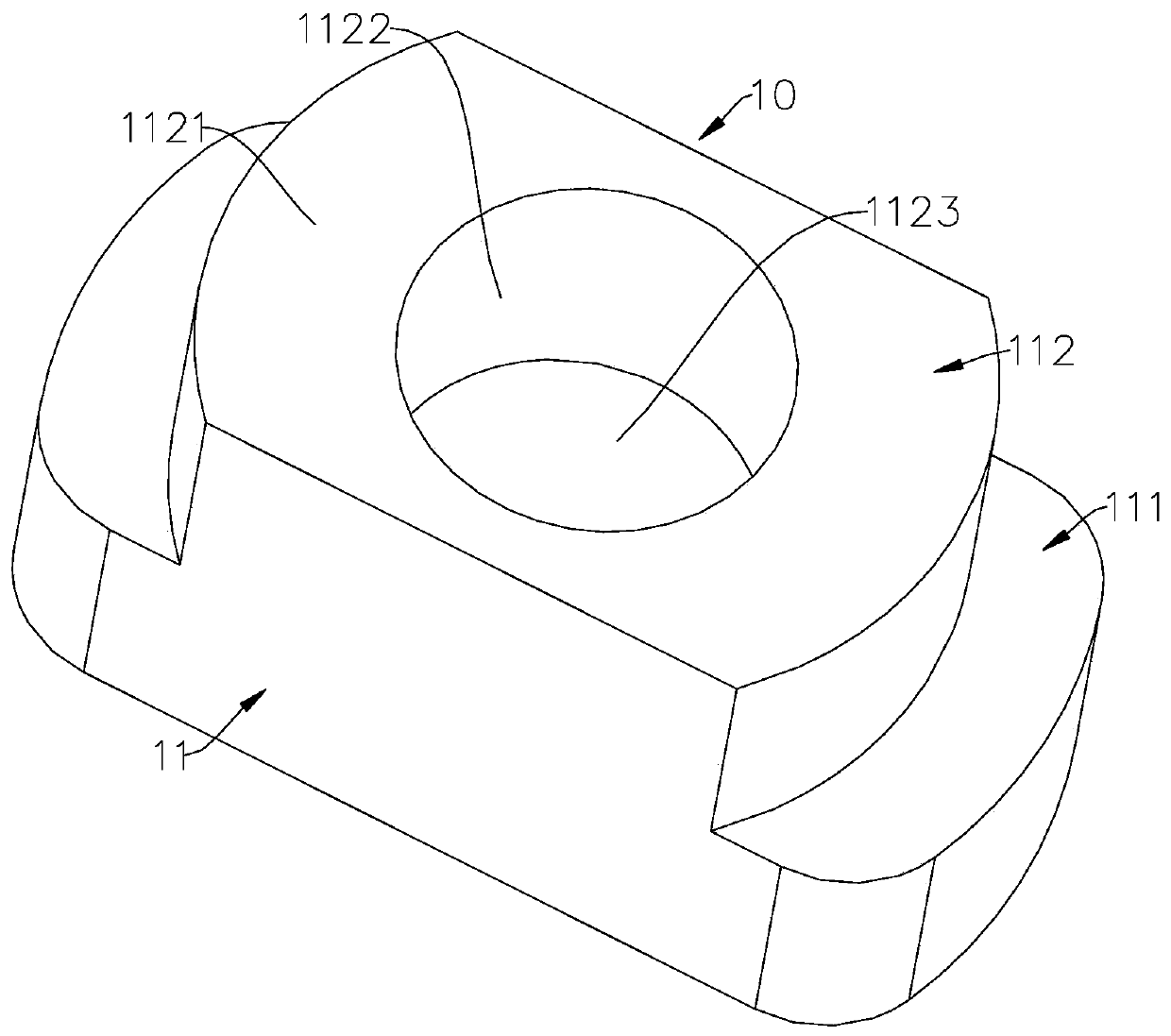

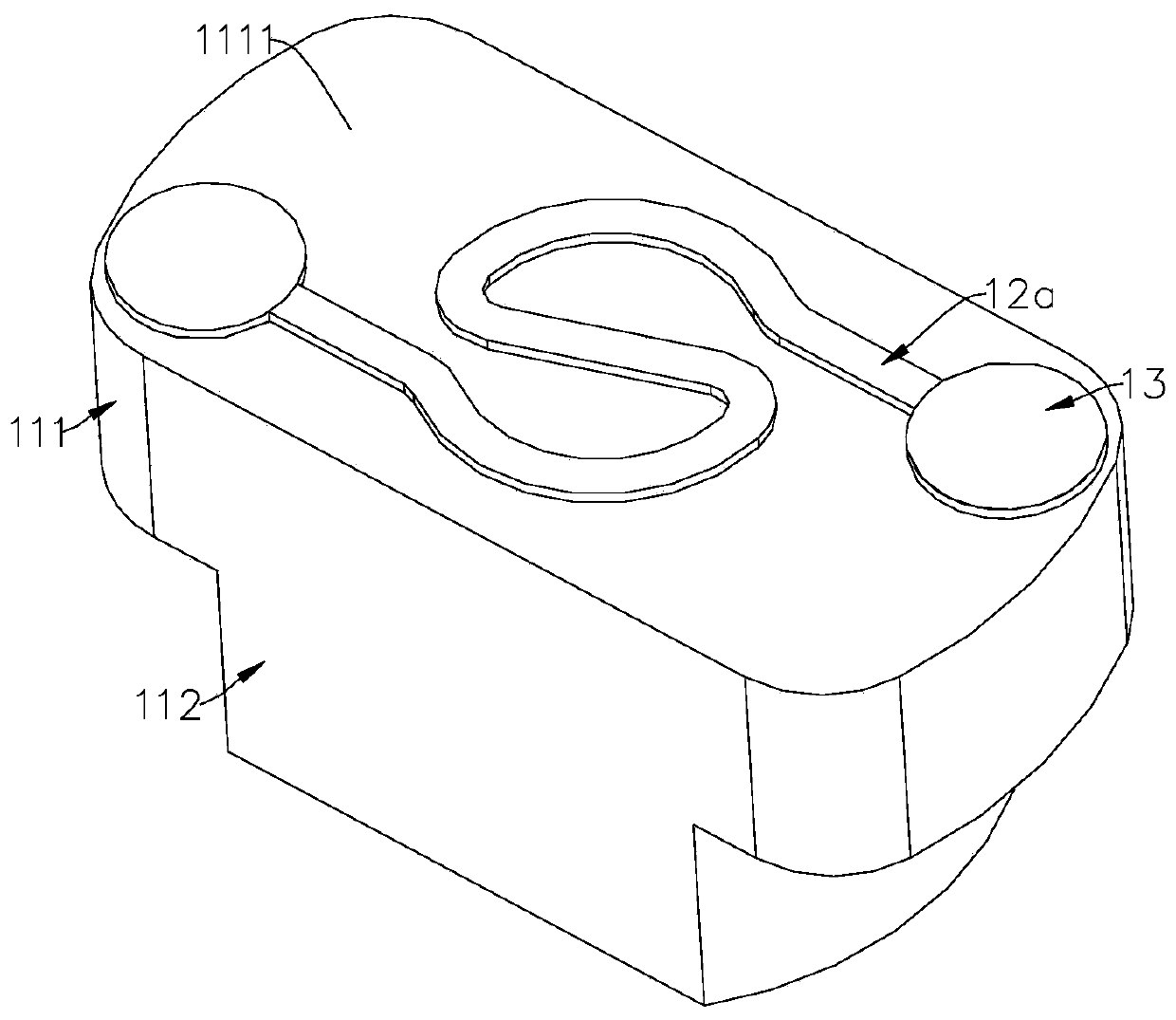

[0041] Figure 2-4 Shown is a heating component 10 in some embodiments of the present invention. The heating component 10 can be used in an atomizer to heat and atomize liquid media such as smoke liquid and medicinal liquid, and it can include a porous body for absorbing liquid media. 11 and a heating element 12a for heating and atomizing the liquid medium adsorbed in the porous body 11. The porous body 11 includes a first surface and a second surface 1121 opposite to each other. Wherein, the first surface is the atomizing surface 1111 for installing the heating element 12a, and the second surface 1121 is recessed inward to form a hole for accommodating the liquid guiding element 20 (see Figure 15 ) of the guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com