Tomato juice auxiliary material addition device

A technology for adding devices and juice auxiliary materials, which is applied to mixers with rotary stirring devices, transportation, packaging, dissolving and other directions, can solve the problems of uneven mixing of auxiliary materials, long mixing time, low production efficiency, etc. The effect of improving the stirring efficiency and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

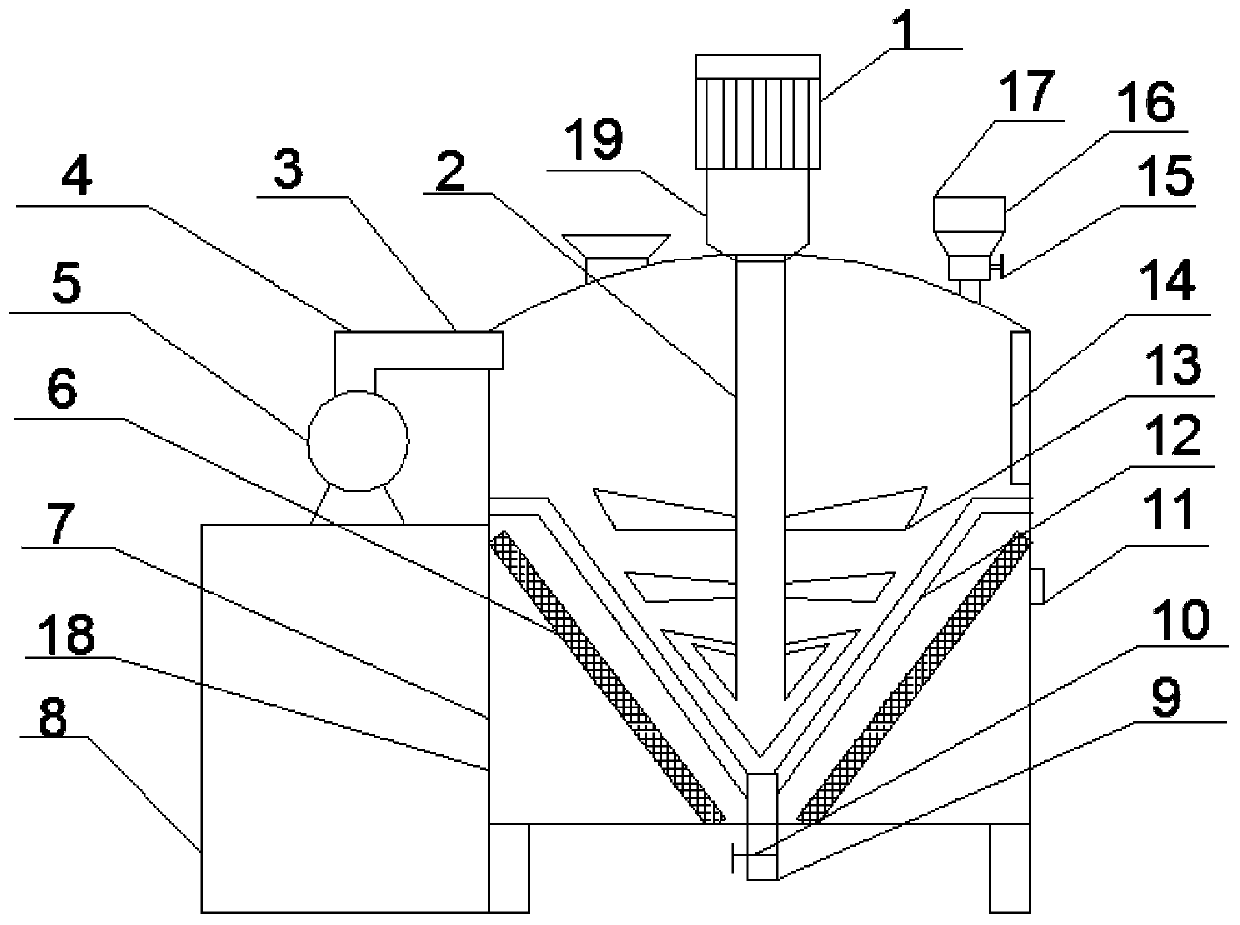

[0028] A tomato juice auxiliary material adding device, comprising a housing 18, the top of the housing 18 is provided with a stirring layer 12, the top of the stirring layer 12 is provided with a stirring motor 1, the driving shaft 19 of the stirring motor 1 is connected to the stirring shaft 2 The other end of the stirring shaft 2 extends into the stirring layer 12, the heating layer 7 is arranged under the stirring layer 12, the lower part of the stirring layer 12 is set in an inverted conical shape, and the stirring shaft 2 is set Stirring blade 13 is arranged, and described stirring blade 13 is arranged as multi-layer, and described stirring blade 13 and stirring layer 12 bottoms are correspondingly reduced successively from top to bottom, and described stirring layer 12 side is provided with glass observation window 14, so The other side of the stirring layer 12 is provided with a water adding device 3 , and the side of the stirring motor 1 is provided with an auxiliary m...

Embodiment 2

[0032] On the basis of Embodiment 1, the water adding device 3 includes a water tank 8, the water tank 8 is connected to one end of the drain pipe 4, the other end of the drain pipe 4 communicates with the stirring layer 12, and the drain pipe 4 A water pump 5 is provided. By setting the water adding device 3, the device can add water to the tomato juice, and it is used in conjunction with the observation window 14 to facilitate the adjustment of the taste of the tomato juice.

Embodiment 3

[0034] On the basis of Embodiment 1, the auxiliary material adding device 17 includes an auxiliary material bin 16 , and a feed valve 15 is arranged at the lower part of the auxiliary material bin 16 . During use, the auxiliary material in the auxiliary material bin 16 will fall into the stirring layer 12 when the feed valve 15 is opened. By setting the auxiliary material adding device 17, it is convenient to add auxiliary materials to the stirring layer 12 at any time, and it is convenient to adjust the taste of tomato juice when used in conjunction with the observation window 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com