Plate punching die

A punching and die technology, used in punching tools, manufacturing tools, metal processing equipment, etc., can solve the problems of small punching force transmission area, weak punch strength, strong pressure, etc., to reduce the mold repair rate, punch The effect of strength improvement and mass productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

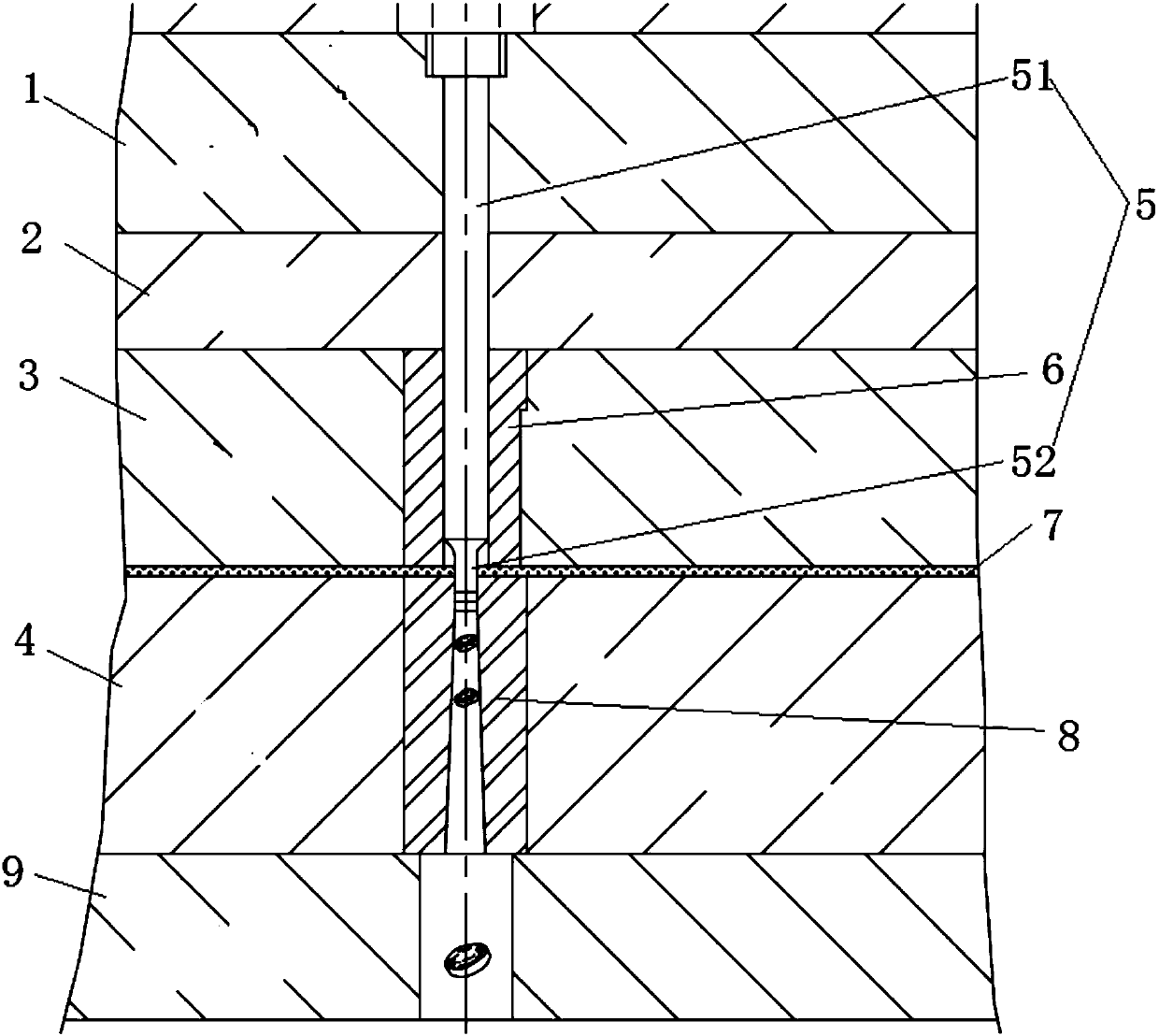

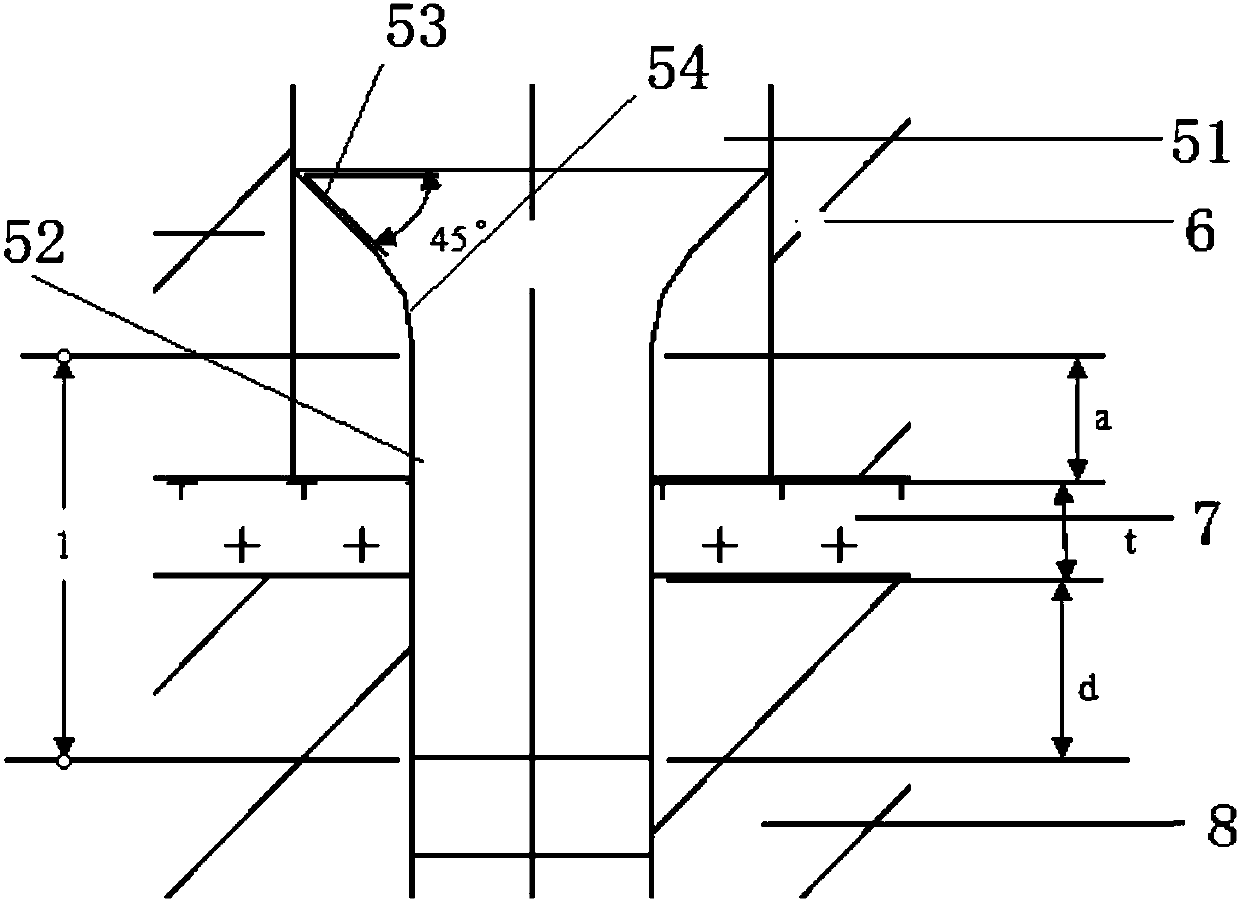

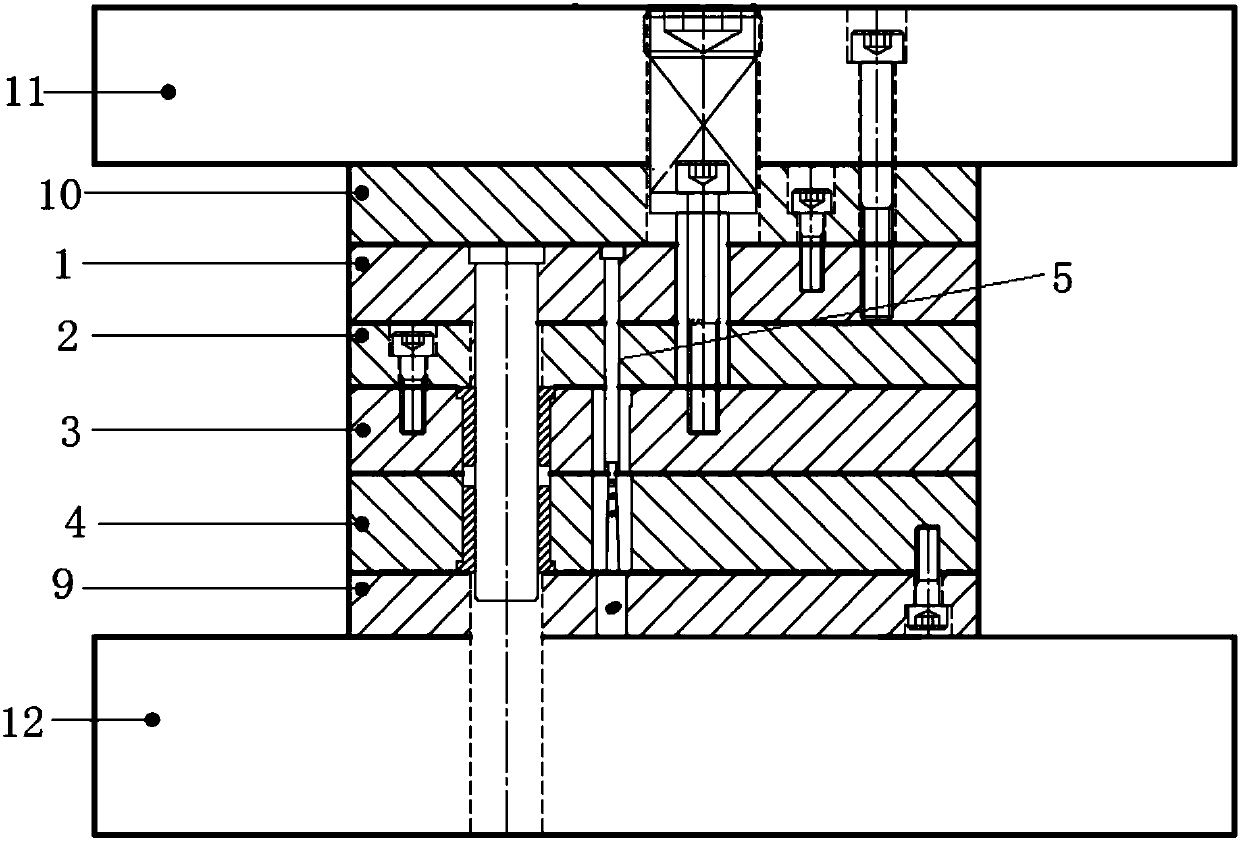

[0021] see Figure 1-3 As shown, a plate punching die includes a punch backing plate 10 and a punch 5 fixed on the punch backing plate through a punch fixing plate 1. There is a discharge material under the punch backing plate 1. Backing plate 2, the lower end of described discharging backing plate is connected with unloading plate 3, and the below of described unloading plate 3 is the concave template 4 that is fixed on the die backing plate 9; Described punch comprises base body portion 51 and diameter To the concentric punching working part 52 whose size is smaller than that of the base part, a cylindrical stripping plate insert 6 is installed in the stripping plate 3 to provide a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap