Manufacturing method and transporting method of steel box girder with high crossbeam

A technology of manufacturing method and transportation method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult matching of parts, prolonging the construction period, and restricting the transportation of box girder sections, so as to reduce the height and improve the stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The embodiment of the present application provides a method for transporting a large girder and a high steel box girder, which includes the following steps:

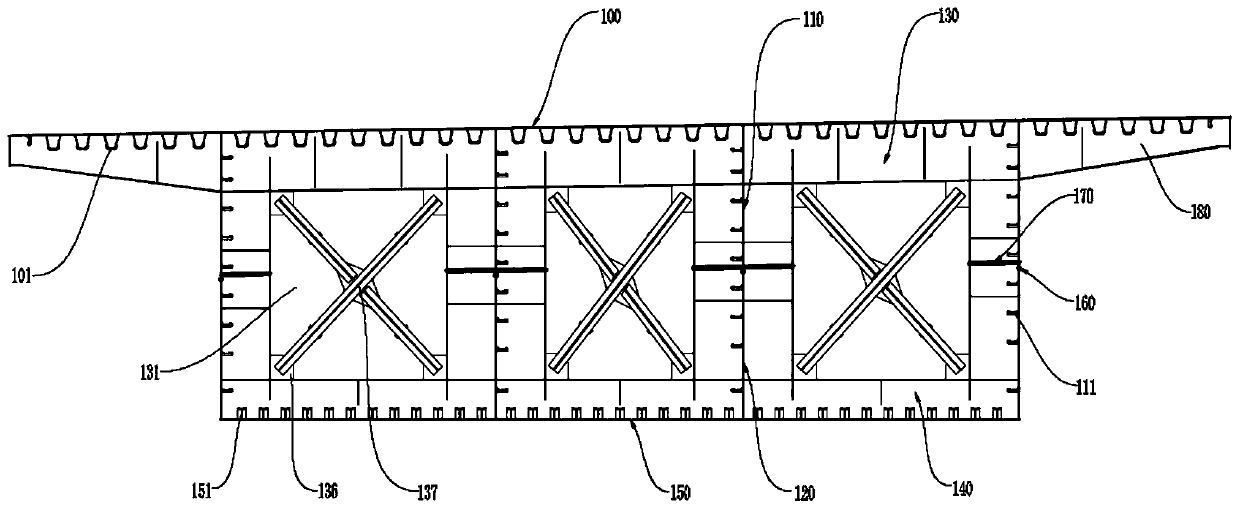

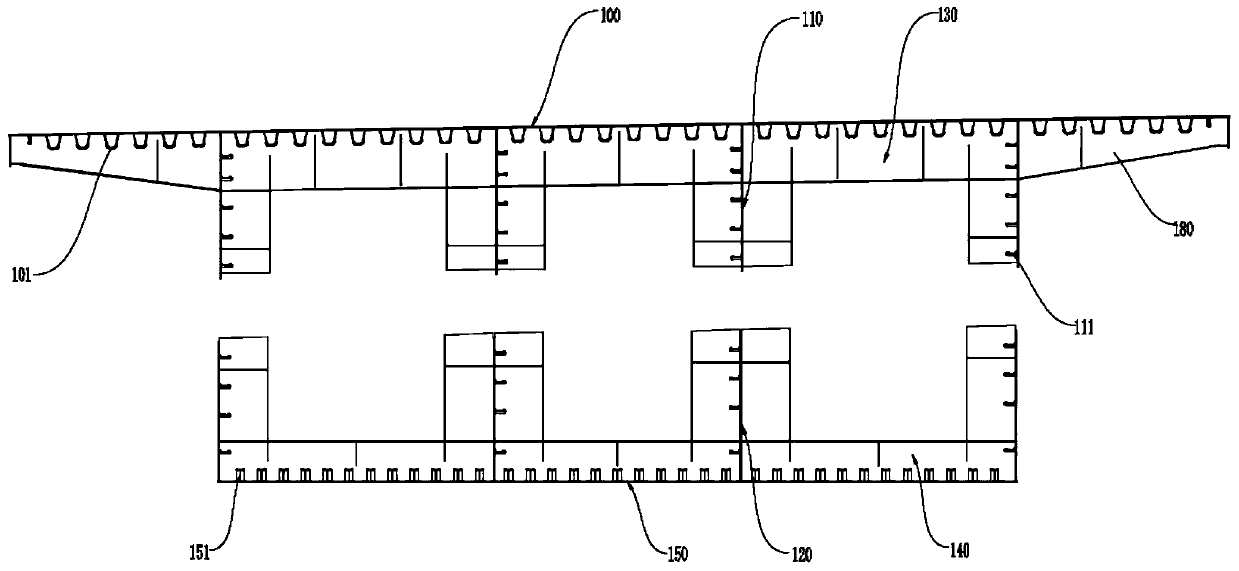

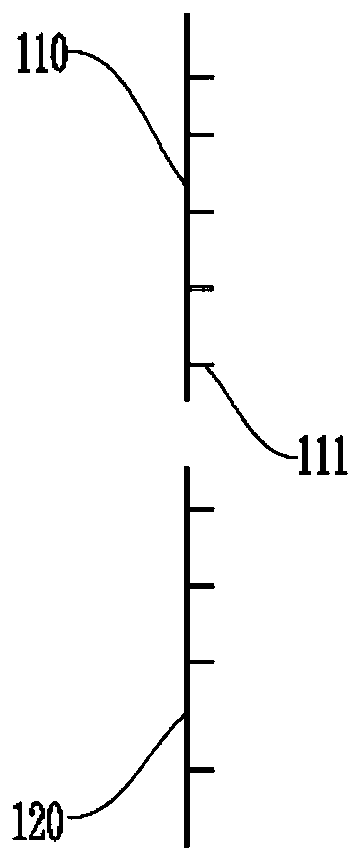

[0062] Please refer to figure 1 , figure 2 , image 3 , Figure 4 As shown, the top plate 100, bottom plate 150, four upper webs 110, four lower webs 120 corresponding to the upper webs 110, three upper partitions 130 and three upper partitions 130 are manufactured respectively. The lower partition 140; wherein, the top plate 100 is prepared by splicing five pre-manufactured top plate units; the bottom plate 150 is prepared by splicing four pre-manufactured bottom plate veneers, and the bottom of the top plate 100 is also connected with thirty Eight U-shaped stiffeners 101 are arranged parallel to each other at intervals. Thirty-five T-shaped stiffeners 151 are connected to each other at intervals on the top of the bottom plate unit. One side of the upper web 110 is connected with five parallel and vertical ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com