Construction method of installing rubber waterstop for automatic folding joint box of underground diaphragm wall

A technology of underground diaphragm wall and rubber waterstop, which is applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of difficult demoulding, easy damage to rubber waterstops and joint boxes, etc. High permeability, high construction efficiency, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to deepen understanding of the present invention, reference will be made below to the attached figure 1 To attach Figure 12 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

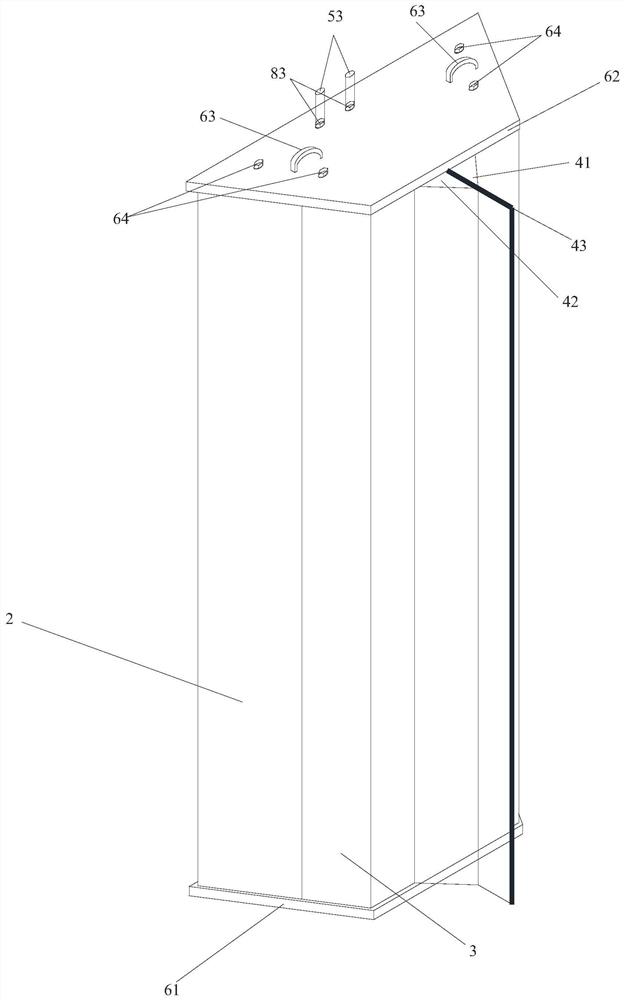

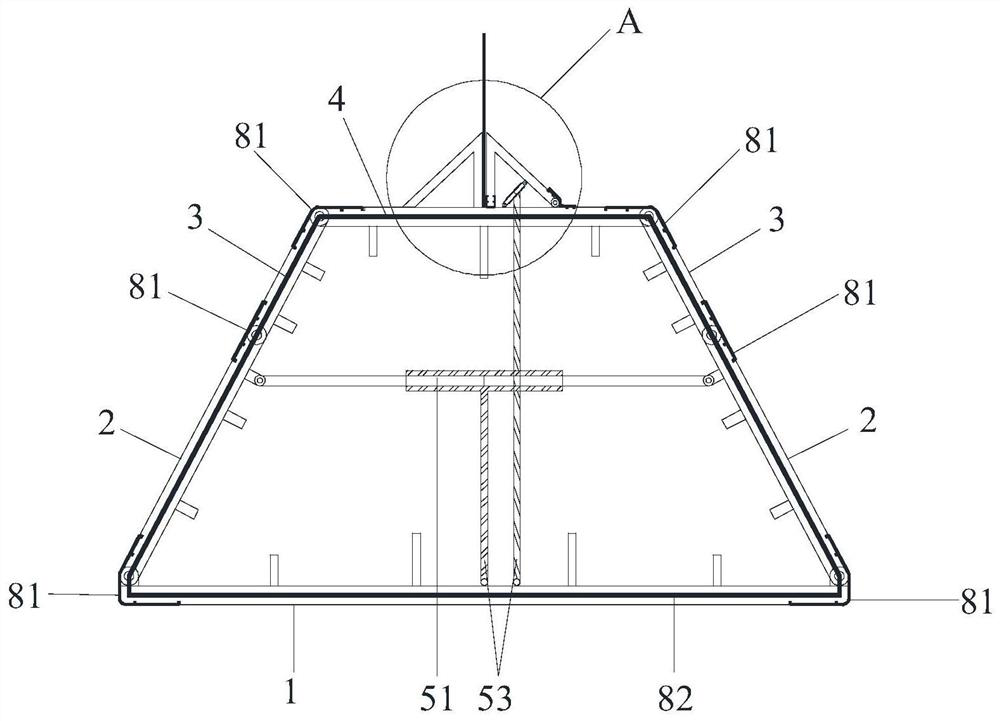

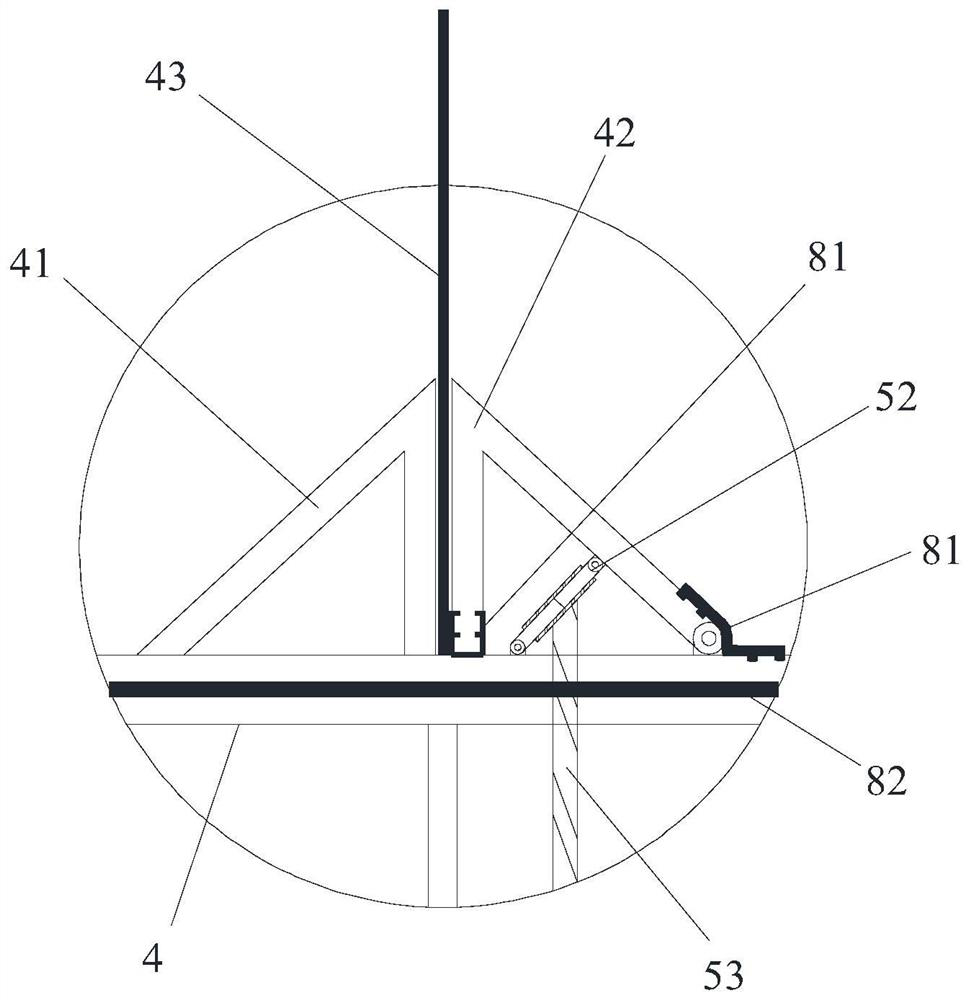

[0045] combined with figure 1 And attached figure 2 As shown, the present invention relates to an automatic folding joint box for a cast-in-situ concrete underground continuous wall, comprising a back panel 1, a rear side panel 2, a front side panel 3, a front panel 4, a folding hydraulic arm 51, a clamping hydraulic arm 52, Lower end plate 61, upper end plate 62 etc. are formed.

[0046] combined with figure 2 , attached Figure 4 ~ attached Figure 6 As shown, the back plate 1, the rear side plate 2, the front side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com