Tunneling smooth surface blasting method

A technology of smooth blasting and tunneling, which is used in blasting, tunneling, earth-moving drilling, etc., can solve the problems of poor smooth blasting effect and large harmful effect of vibration on the uniform light surface, and achieves the goal of improving the destructive effect and ensuring the blasting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

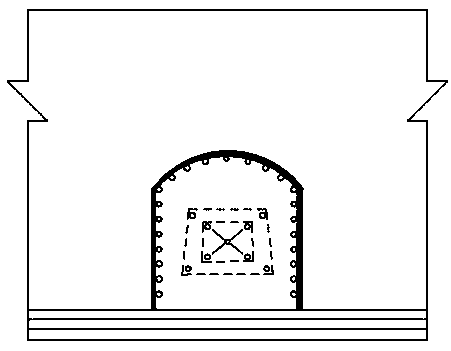

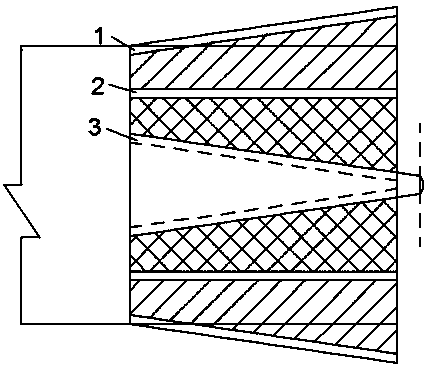

[0040] Embodiment 1: as Figure 1~4 As shown, a smooth blasting method for tunnel excavation, uniformly open smooth blasting holes on the tunnel rock (see figure 1 with figure 2 ), the uncoupled charge device for smooth blasting is placed in the smooth blasting hole, and the digital electronic detonator is used to realize the smooth hole-by-hole precise short-delay blasting of tunnel excavation;

[0041] The distance between the smooth blast holes is 8~12 times of the blast hole diameter, and the delay time of the digital electronic detonator is 9~12ms;

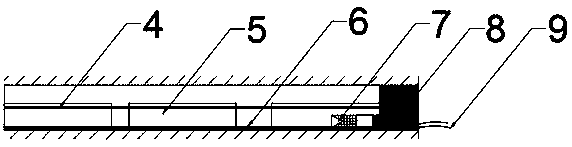

[0042] The uncoupled charge device for smooth surface blasting is structure A (see image 3 ): The uncoupled charging device for smooth blasting includes charge volume fixed arc plate III6, explosive charge roll I5, detonating cord I4, digital electronic detonator III7, explosive charge roll I5 is fixedly arranged on charge roll fixed arc plate III6 , the detonating cord I4 is sequentially connected to the explosive charg...

Embodiment 2

[0053] Embodiment 2: a kind of smooth surface blasting method of tunnel excavation, evenly offer smooth surface blasting hole on tunnel rock (see figure 1 with figure 2 ), the uncoupled charge device for smooth blasting is placed in the smooth blasting hole, and the digital electronic detonator is used to realize the smooth hole-by-hole precise short-delay blasting of tunnel excavation;

[0054] The distance between the smooth blast holes is 8~12 times of the blast hole diameter, and the delay time of the digital electronic detonator is 9~12ms;

[0055] The uncoupled charging device for smooth surface blasting is structure B: including digital electronic detonator I14 arranged at the bottom of the smooth surface blasting hole, the top of digital electronic detonator I14 is equipped with explosive binding device, and the top of explosive binding device is equipped with digital electronic detonator II10 , the leg wires of digital electronic detonator I14 and digital electronic...

Embodiment 3

[0071] Embodiment 3: A smooth blasting method for tunnel excavation, using an uncoupled charge device for smooth blasting, the specific steps are as follows:

[0072] (1) Choose Φ 32mm, emulsified explosive roll, length 30cm, weight 300g, density 0.95-1.30g / cm 3 , the explosive roll with a detonation distance of 3cm:

[0073] (2) Select the medicine coil to fix the curved plate and drug roll fixed arc plate , drug roll fixed arc plate and drug roll fixed arc plate The outer diameter is 34mm, the wall thickness is 2mm, and the cutting length is 1m; and drug roll fixed arc plate The outer diameter is adapted to the diameter of the smooth blast hole and the length is adapted to the explosive roll, and the explosive roll is bound to the fixed curved plate of the charge roll and drug roll fixed arc plate In the cavity between the inner walls of the explosive rolls and ensure that the adjacent explosive rolls have a certain distance, that is, 2 / 5 of the charge roll fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com