Patch position error detection method based on digital image

A digital image and error detection technology, which is applied in image enhancement, image analysis, image data processing, etc., can solve the problems of not meeting the requirements of fast production and high time cost, and achieve the improvement of template matching speed, extraction speed and noise reduction interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Embodiments of the present invention and its implementation process are as follows:

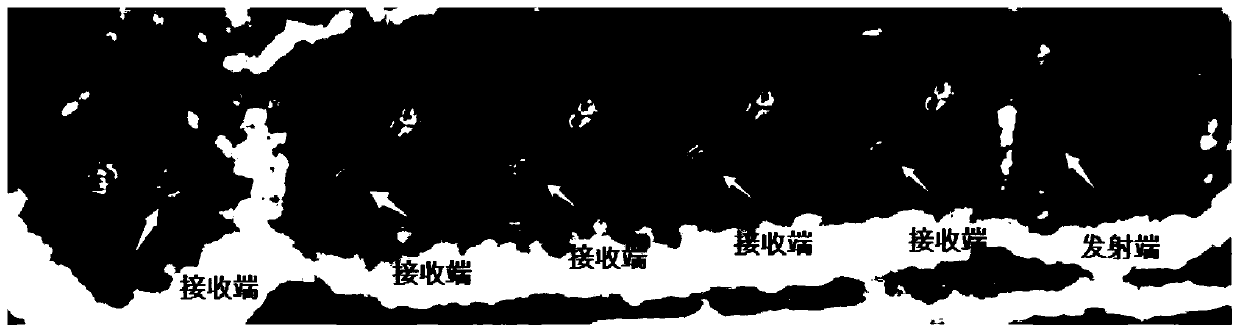

[0049] The optical fiber transceiver PCB board processed by the embodiment of the present invention is photographed by an industrial camera and obtained as follows: figure 1 As shown, it includes 5 receiver chips and 1 transmitter chip such as figure 2 shown. In order to make the above chips and optical fibers with equal distances butt joints, it is required that the positions of the above six chips are equally spaced. The four center points on the center wafer have been arranged at equal intervals, so it is necessary to detect whether the left and right center points meet the error requirements.

[0050] 1) The weighted mean filter is used to denoise the image, and the image histogram equalization is used to improve the image contrast, and the impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com