Wafer processing method

A processing method and chip technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve problems such as device defects, quality degradation, and difficult positioning of pressing blades, and achieve the effect of overcoming quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

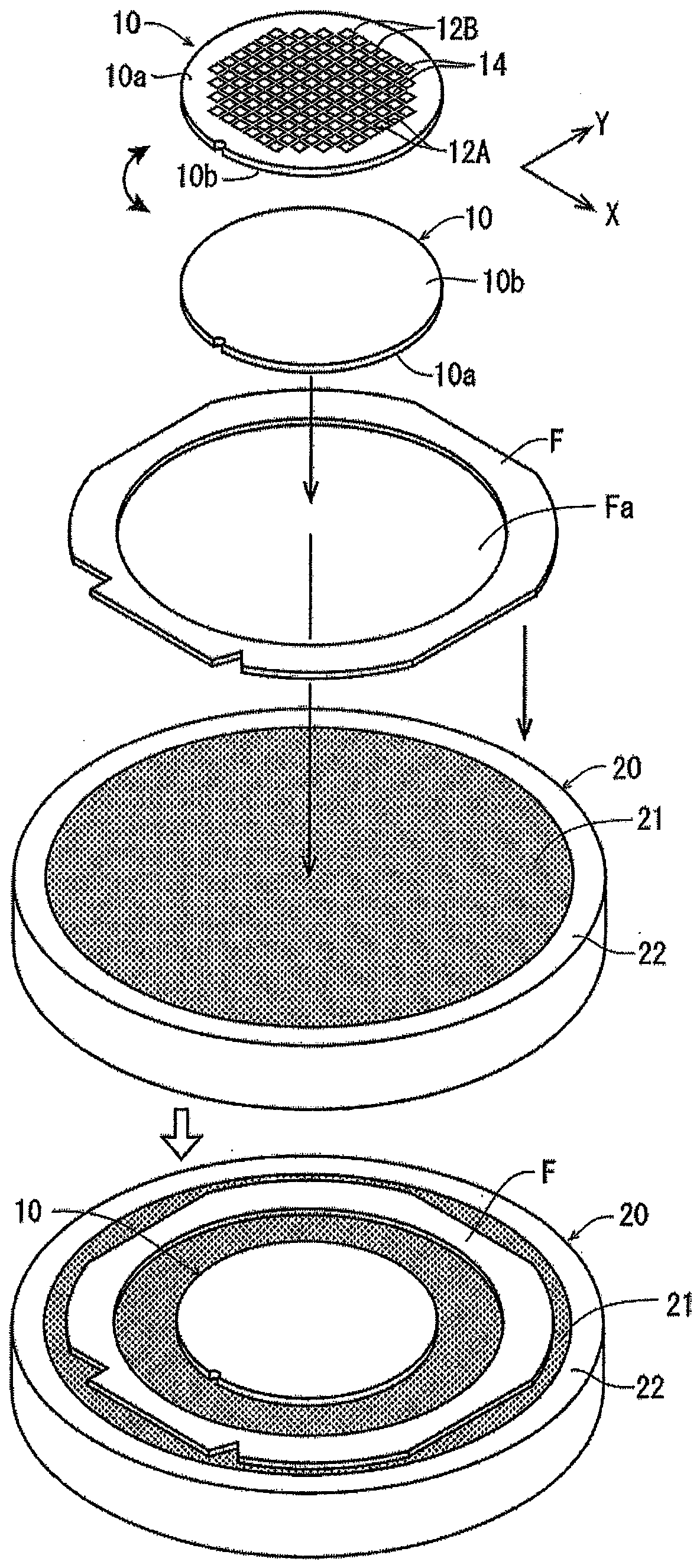

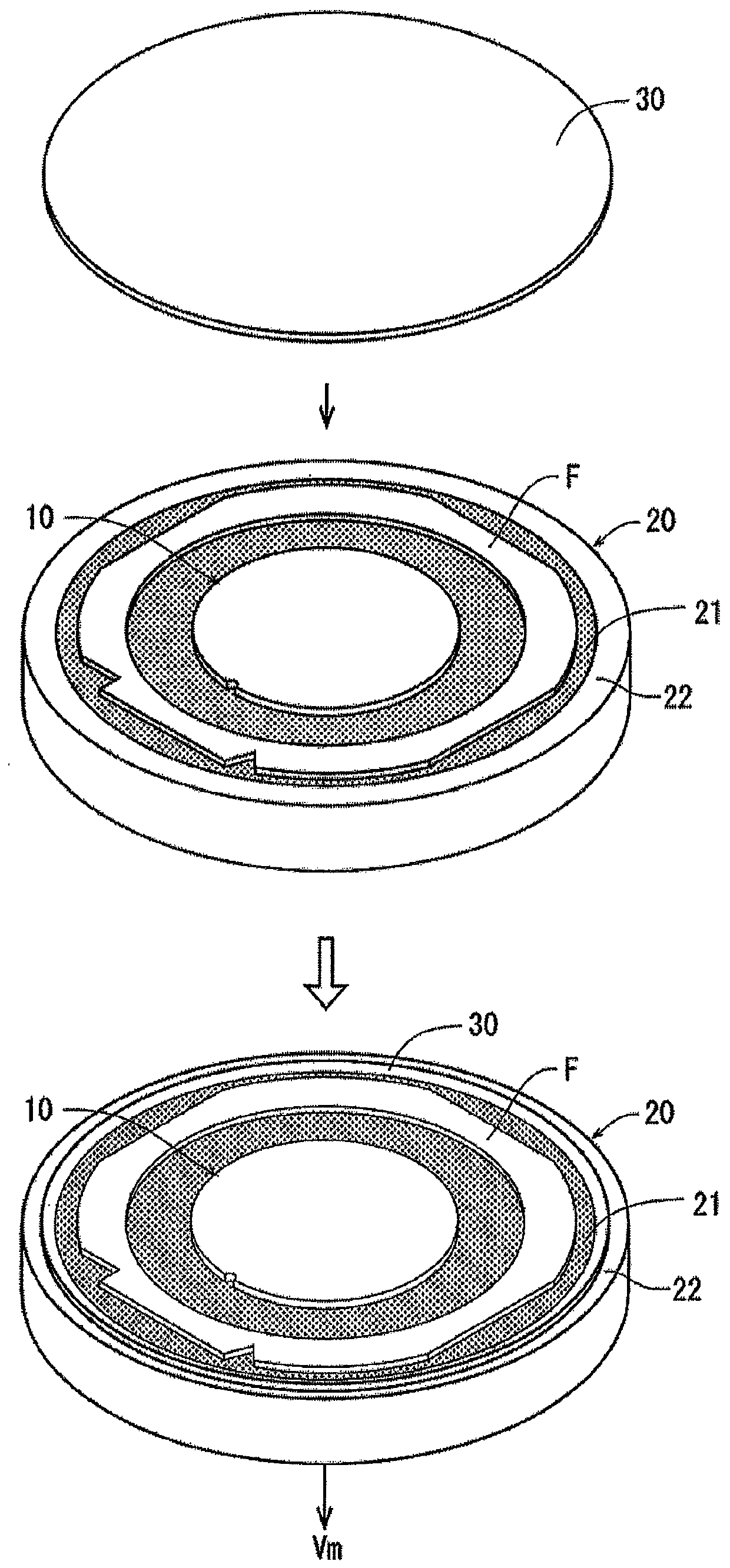

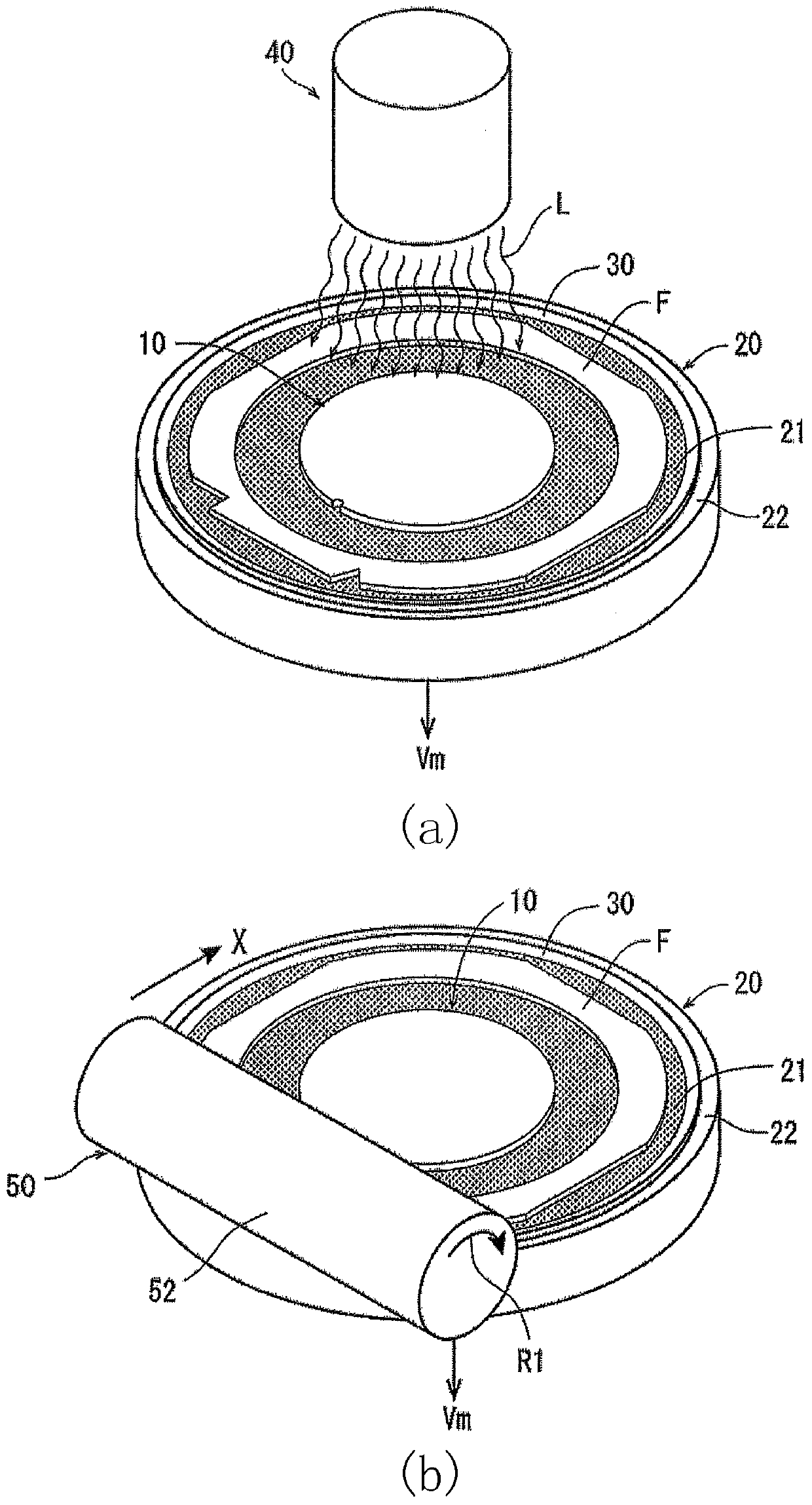

[0022] Hereinafter, each step of the wafer processing method according to the present invention will be described in order.

[0023] (Polyester sheet laying process)

[0024] refer to figure 1 and figure 2 , and the polyester-based sheet laying process will be described. exist figure 1 A perspective view of an embodiment of the polyester-based sheet laying step is shown in . When implementing the laying process of polyester sheets, first of all, as figure 1 As shown, a wafer 10 as an object to be processed, a ring frame F having an opening Fa capable of accommodating the wafer 10 , and a chuck table 20 for performing a polyester-based sheet laying process are prepared. The wafer 10 is made of, for example, a silicon (Si) substrate, and the devices 14 are formed on a first planned division line 12A formed along a first direction indicated by an arrow X and a second line indicated by an arrow Y intersecting at right angles to the first direction. On the front side 10a div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com