Single-pressure sliding type hill-drop planter with adjustable row spacing

A technology of hole seeder and plant spacing, applied in the direction of seeder parts, etc., can solve the problems of large seeding volume, poor flexibility, and easy lack of nests for large seeds, so as to achieve high seeding accuracy, cost reduction, and strong universality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

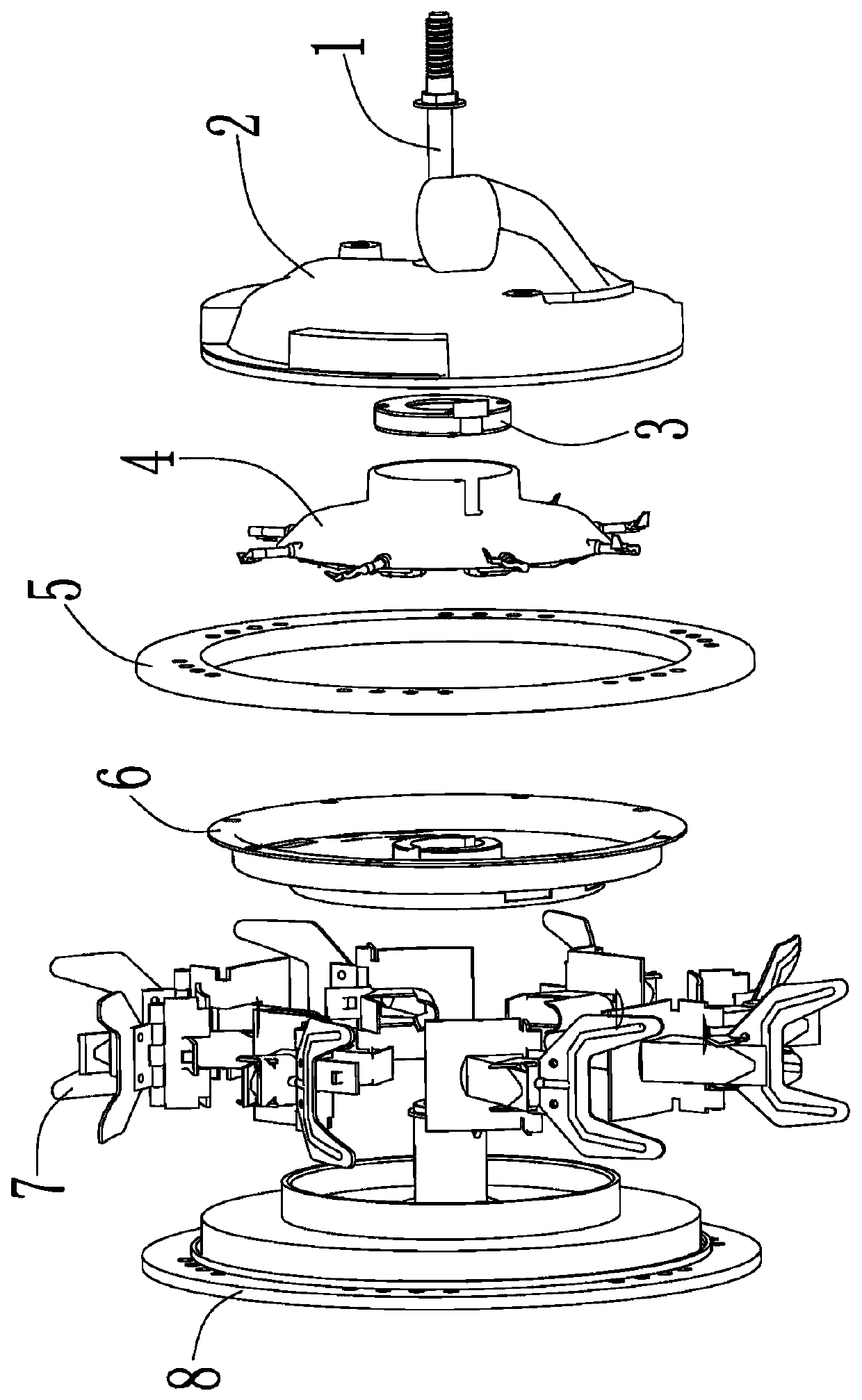

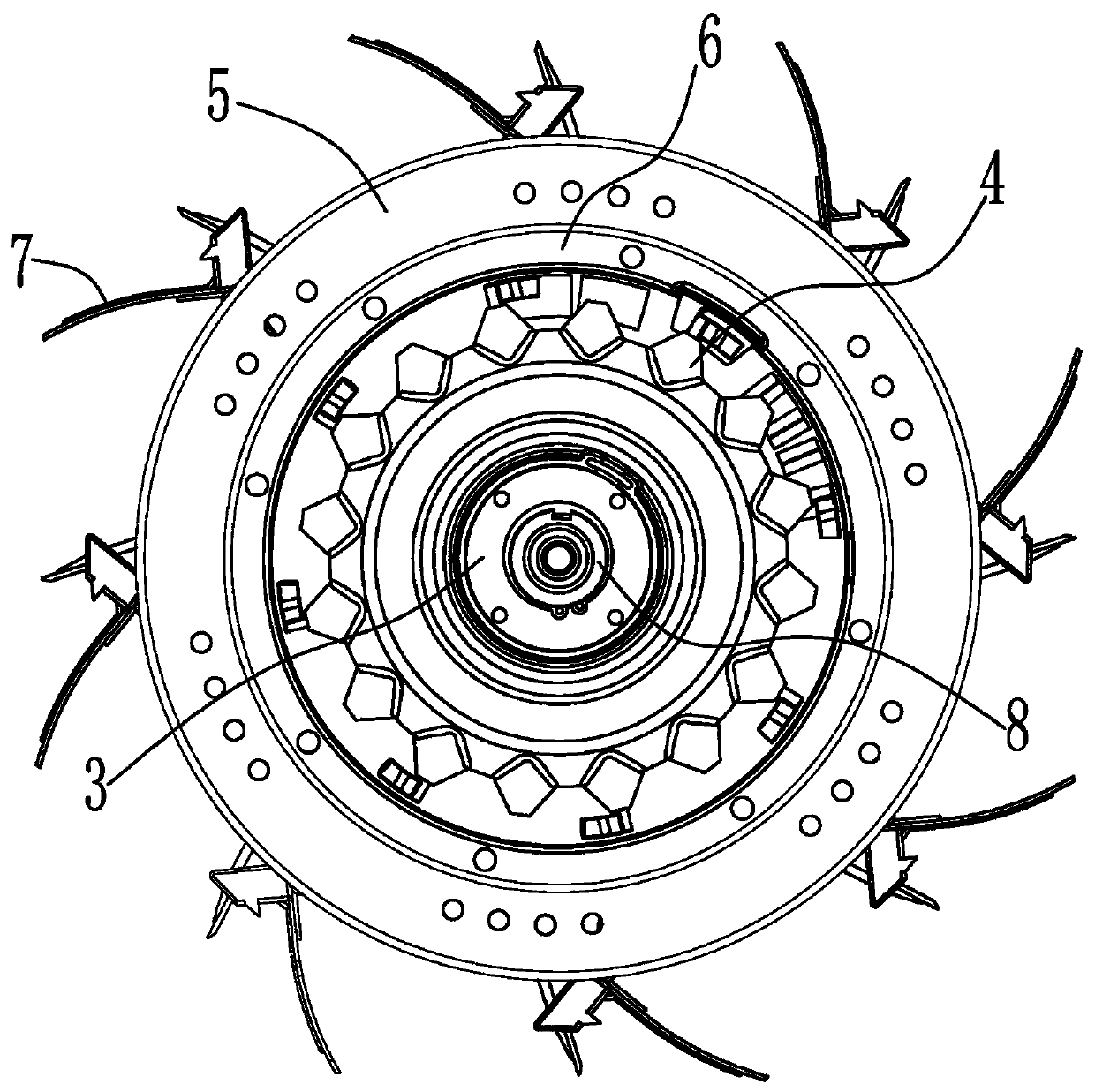

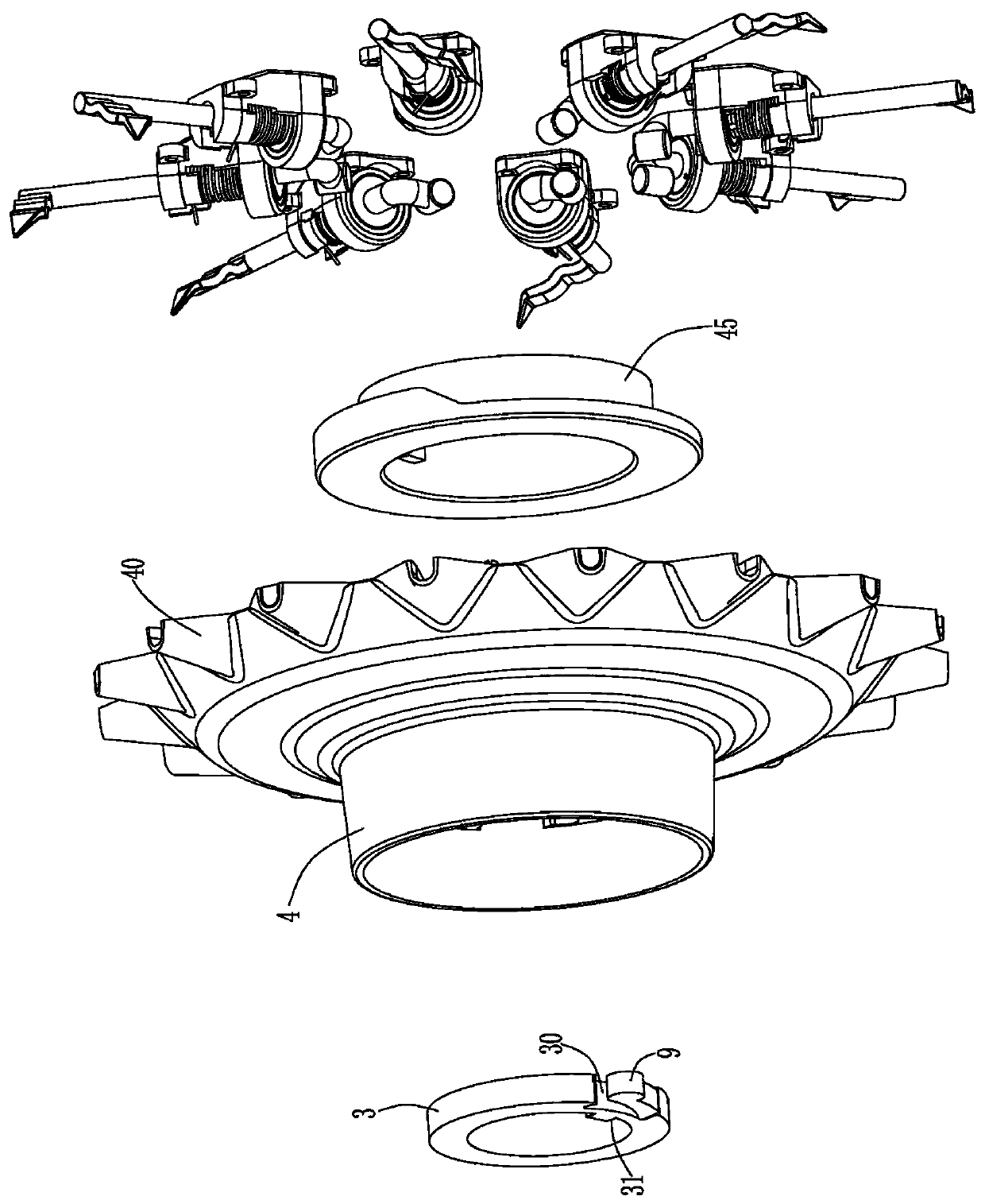

[0008] Embodiment, a kind of adjustable single-pressure sliding hole planter with plant spacing, as attached Figure 1-12 As shown, from left to right, the rotating shaft 1, the fixed plate 2, the ratchet 3, the seed picking chuck 4, the seed separation plate 6, the duckbill assembly 7, the moving plate 8 and the pressure plate 5 are connected together concentrically and coaxially , the above-mentioned technical components are all prior art, and its connection mode and seed-taking action and mode are all disclosed. But wherein the structural design of the seed chuck 4 and the structural design of the ratchet 3 are the latest designs, and are also the invention points that this patent application emphasizes for protection. The described seed chuck 4 includes a seed seat 41, several mutually independent Clamp bar assembly and several independent seed-taking boxes 42 and drive core discs 45 adapted to the clamp bar assembly. In the prior art, the structure of the clamp bar assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com