Linear welding robot

A linear welding and welding machine technology, applied in the field of robots, can solve the problems of poor welding stability, low welding efficiency, and large weld seam gaps, and achieve the effects of fast welding speed, improved welding efficiency, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

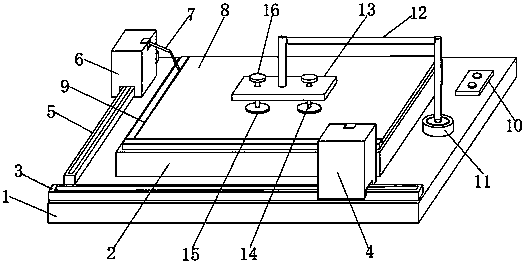

[0013] A linear welding robot comprises an installation base plate 1, a welding platform 2 is arranged in the middle of the upper surface of the installation base plate 1, a first welding machine slide rail 3 is fixed on the front side of the upper surface of the installation base plate 1, and the first A first welding machine trolley 4 is installed on the welding machine slide rail 3, a second welding machine slide rail 5 is fixed on the left side of the upper surface of the installation base plate 1, and a second welding machine slide rail 5 is installed on the second welding machine slide rail 5. Machine trolley 6, a welding trolley control switch 10 is installed on the right side of the upper surface of the installation base plate 1, and the welding trolley control switch 10 is respectively connected to the first welding machine trolley 4 and the second welding machine trolley 6. The welding platform 2 is placed with a workpiece 8, the left side and the front side of the wo...

Embodiment 2

[0015] A linear welding robot comprises an installation base plate 1, a welding platform 2 is arranged in the middle of the upper surface of the installation base plate 1, a first welding machine slide rail 3 is fixed on the front side of the upper surface of the installation base plate 1, and the first A first welding machine trolley 4 is installed on the welding machine slide rail 3, a second welding machine slide rail 5 is fixed on the left side of the upper surface of the installation base plate 1, and a second welding machine slide rail 5 is installed on the second welding machine slide rail 5. Machine trolley 6, a welding trolley control switch 10 is installed on the right side of the upper surface of the installation base plate 1, and the welding trolley control switch 10 is respectively connected to the first welding machine trolley 4 and the second welding machine trolley 6. The welding platform 2 is placed with a workpiece 8, the left side and the front side of the wo...

Embodiment 3

[0018] A linear welding robot comprises an installation base plate 1, a welding platform 2 is arranged in the middle of the upper surface of the installation base plate 1, a first welding machine slide rail 3 is fixed on the front side of the upper surface of the installation base plate 1, and the first A first welding machine trolley 4 is installed on the welding machine slide rail 3, a second welding machine slide rail 5 is fixed on the left side of the upper surface of the installation base plate 1, and a second welding machine slide rail 5 is installed on the second welding machine slide rail 5. Machine trolley 6, a welding trolley control switch 10 is installed on the right side of the upper surface of the installation base plate 1, and the welding trolley control switch 10 is respectively connected to the first welding machine trolley 4 and the second welding machine trolley 6. The welding platform 2 is placed with a workpiece 8, the left side and the front side of the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com