A kind of method extracting lithium sulfate from lepidolite

A technology of lepidolite and lithium sulfate, which is applied in the direction of lithium sulfate/sulfite, etc., can solve the problems of increased loss rate of rare metal materials, low equipment efficiency, and increased cost, so as to achieve stable soluble lithium rate and benefit Environmentally friendly, improving the effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

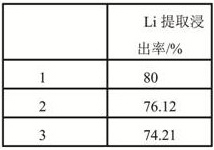

Examples

Embodiment 1

[0039] A method for extracting lithium sulfate from lepidolite disclosed by the present invention is to use lepidolite as raw material and auxiliary material after mixing, and then to extract lithium by roasting in a rotary kiln device after mixing the raw material and auxiliary material, which is as follows The steps are carried out: the raw material used in this embodiment is the lepidolite raw material produced by the Yichun tantalum-niobium-lithium mine, and its main chemical composition is as follows in Table 1 (wt%), and the balance is fluorine,

[0040] Table 1 takes the lepidolite raw material produced by Yichun tantalum-niobium-lithium mine. Its main chemical composition is as follows (wt%) and the balance is fluorine.

[0041] Li 2 o

K 2 o

Na 2 o

AL 2 o 3

SiO 2

Fe 2 o 3

Rb 2 o

Cs 2 o

5.45 10.68 0.52 23.64 53.34 0.31 1.54 0.42

[0042] 1), crushing, crushing lepidolite into 50-80 mesh lepidolit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com