A Recoatable Flexible Fluorocarbon Coating

A fluorocarbon coating and flexible technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of steel bridge erosion, loss of protection benefits, cracks and other problems, and achieve comprehensive improvement. Application performance, excellent weather resistance, crack reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

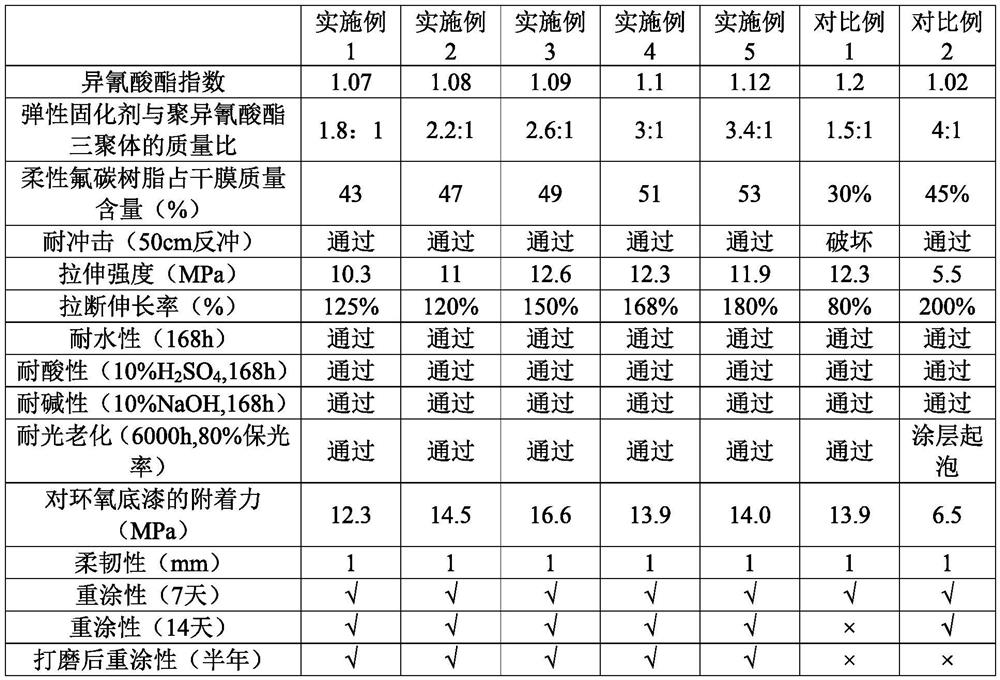

Examples

Embodiment 1

[0029] A recoatable flexible fluorocarbon coating according to the invention is a two-component system of A and B.

[0030] Component A: Add 47.2Kg fluorocarbon resin (AGC LF600X) and 4.8Kg butyl acetate into the mixing tank, add 1.63Kg thixotropic agent (Degussa R972), and disperse at a high speed of 800r / min for 20min to uniform;

[0031] Add 0.23Kg dispersant (Digo 610s) at 500r / min speed, after dispersing for 10 minutes, add 13.8Kg rutile titanium dioxide (R818), 0.5Kg carbon black (N660), 1Kg medium chrome yellow, 1.4Kg treated modified Dry wollastonite powder, after dispersing for 30 minutes, grind to fineness below 30μm;

[0032] Add 0.36Kg substrate wetting agent (Digo 450), 0.23Kg defoamer (Merck MOK6021), 0.64Kg light stabilizer (Ciba 5151) and the remaining butyl acetate solvent, at 600r / min Disperse for 20 minutes until uniform, and obtain A component.

[0033] B component: Add 3Kg butyl acetate, 1.9Kg HDI trimer (Bayer 3390) and 12Kg elastic curing agent (Asahi...

Embodiment 2

[0035] A recoatable flexible fluorocarbon coating according to the invention is a two-component system of A and B.

[0036] A component: including 51.5Kg fluorocarbon resin (AGC LF600X), 13.2Kg rutile titanium dioxide (R818), 0.2Kg carbon black (N660), 1.3Kg treated modified wollastonite powder, 1.5Kg bentonite (BP- 183B), 0.2Kg dispersant (Digo 628), 0.2Kg defoamer (Merck MOK6021), 0.62Kg light stabilizer (Ciba 5151), 0.34Kg substrate wetting agent (Digo Wet KL 245 ), 6Kg butyl acetate, 9Kg xylene, the preparation method is with embodiment 1.

[0037] B component: including 10.9Kg elastic curing agent (Asahi Kasei E405-80T), 1.8Kg HDI trimer (BASF HI190B / S), 2.9Kg butyl acetate, the preparation method is the same as in Example 1.

Embodiment 3

[0039] A recoatable flexible fluorocarbon coating according to the invention is a two-component system of A and B.

[0040] A component: including 53.6Kg fluorocarbon resin (AGC LF600X), 12.4Kg rutile titanium dioxide (R962), 1.2Kg treated modified wollastonite powder, 10Kg hyperdispersive rheology additive (Hemings Deqian Benge1828), 1.4Kg wetting and dispersing agent (byk163), 0.21Kg defoamer (BASF Efka EFKA2722), 0.57Kg light stabilizer (Ciba 5151), 0.32Kg substrate wetting agent (Di High tego450), 5Kg butyl acetate, 7.8Kg xylene, 1.2Kg ethylene glycol ethyl ether acetate, preparation method is with embodiment 1.

[0041] B component: including 10.3Kg elastic curing agent (Asahi Kasei E402-90T), 1.7Kg HDI trimer (BASF HI190B / S), 2.6Kg butyl acetate, the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com