Drainage control method of clothes processing device and multi-tub clothes processing device

The technology of a clothes processing device and a control method is applied to the control device of a washing machine, a washing device, other washing machines, etc., and can solve problems such as backwashing and clothes contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

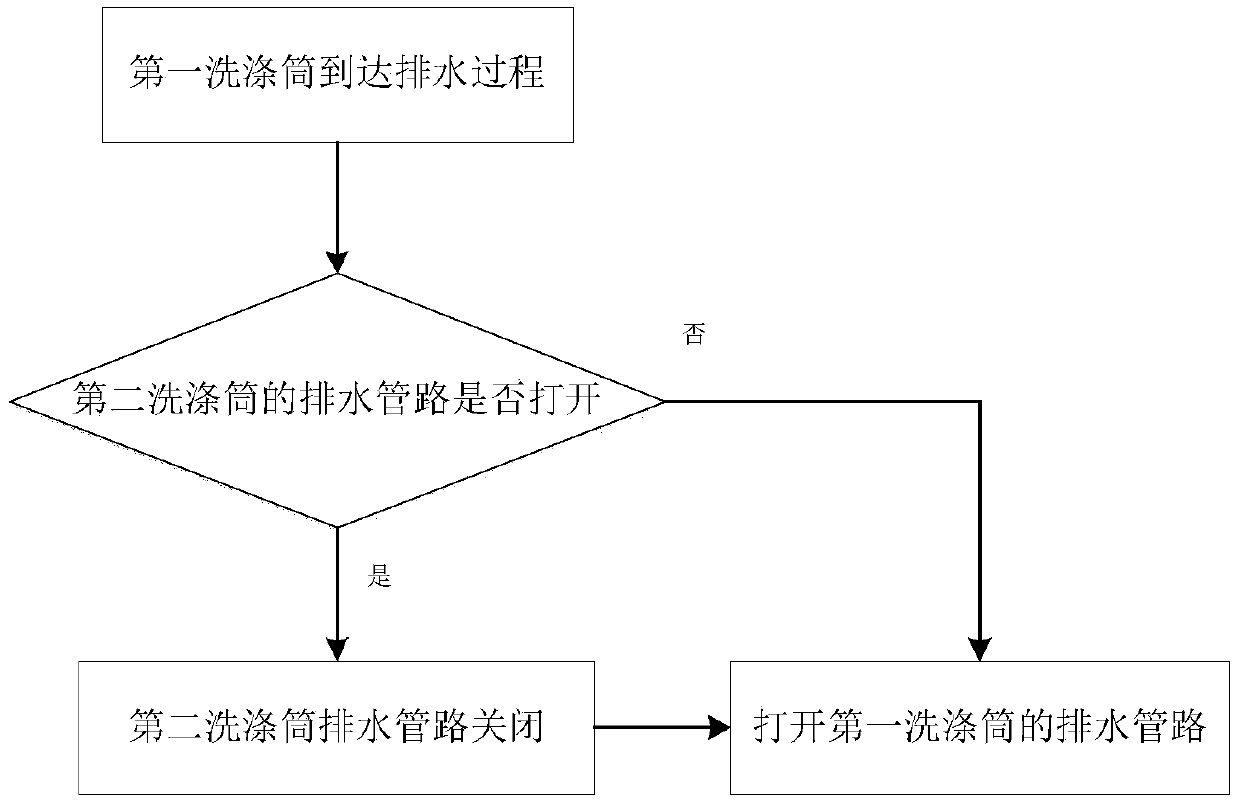

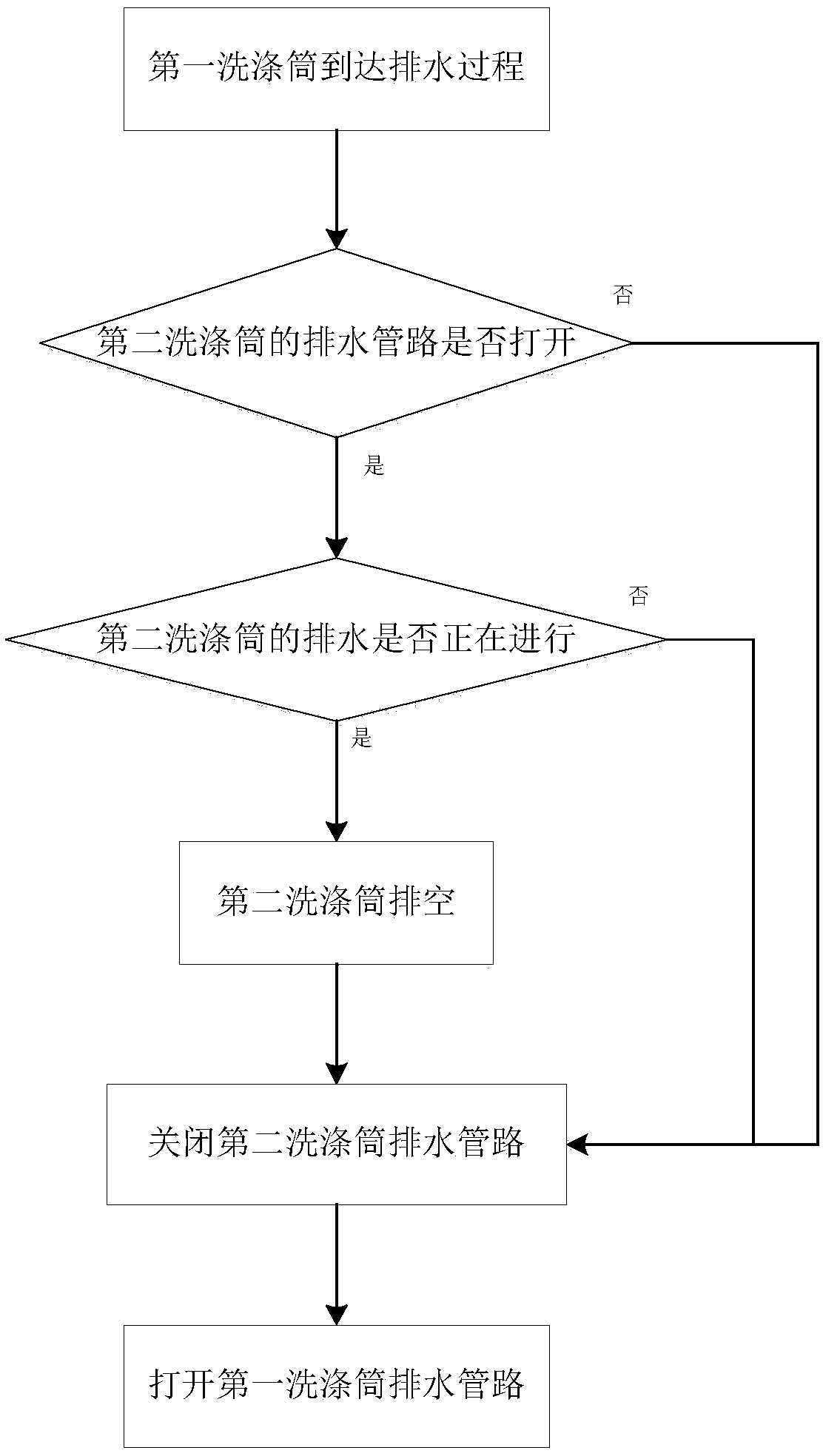

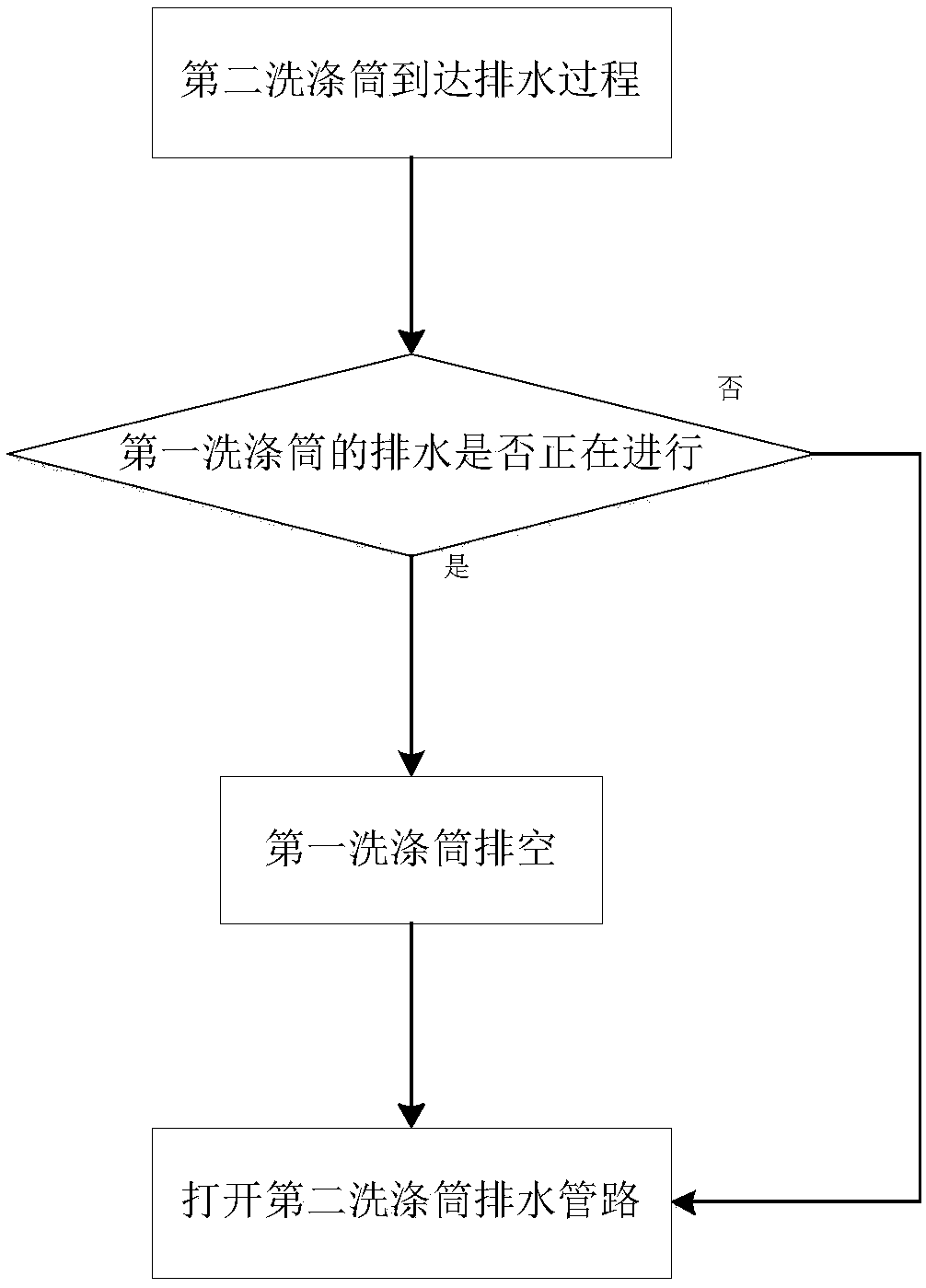

Embodiment 1

[0040] Such as Figure 1 to Figure 3 As shown, this embodiment discloses a method for controlling drainage of a laundry treatment device. The clothes processing device in this embodiment is a multi-tub washing machine, including at least a first washing tub and a second washing tub, the washing, dehydration and draining processes of the first washing tub and the second washing tub are independent, and each passes through The drainage pipeline of the first washing tub and the drainage pipeline of the second washing tub perform drainage, and the drainage pipelines of the first washing tub and the second washing tub are respectively controlled by independent control devices to switch the on / off state of the respective drainage pipelines. In addition, the drainage pipelines of the first washing tub and the second washing tub are connected and connected to the same main drainage pipeline, and the washing water is discharged out of the machine body through the main drainage pipeline...

Embodiment 2

[0046] Such as Figure 4 and Figure 5 As shown, this embodiment is a further supplement to the fact that the washing tub in embodiment 1 performs a dehydration program. In this embodiment, when the first washing tub is dehydrating from a low-rotation speed to a high-rotation speed, the drainage pipeline of the second washing tub is closed. When the dehydration of the first washing tub is stable at a high-speed dehydration state, the drainage pipeline of the second washing tub can be opened. This is because when the clothes processing device is performing the dehydration program, the amount of drained water will increase significantly when the speed increases from low speed to high speed, and this is the most concentrated period of water discharge in the dehydration stage. Therefore, similar to Embodiment 1, in order to prevent the washing water from being poured back into the washing tub from the drain pipe, the drain pipes of each washing tub are also controlled similarly ...

Embodiment 3

[0050] Such as Figure 6 As shown, this embodiment discloses a multi-tubular laundry treatment device using the method for controlling the drainage of the laundry treatment device described in the above embodiments.

[0051] Such as Figure 6 As shown, the laundry treatment device includes a housing 9, in which at least a first washing tub 8 and a second washing tub 7 are disposed. As shown in the figure, the first washing tub 8 is located on the upper part of the second washing tub 7 , and the drainage height of the first washing tub 8 is higher than that of the second washing tub 7 .

[0052] The multi-tube laundry processing device in this embodiment is an upper drainage clothing processing device. The main drainage pipe 2 is provided with a drainage pump 4, and the drainage pump 4 is used to pump the washing water in the main drainage pipe 2 out of the body to complete the washing process. The drainage process of the treatment plant. The drainage pipeline 3 of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com