A kind of sma negative stiffness damping device

A shock-absorbing device, negative stiffness technology, applied in the direction of earthquake resistance, building type, building, etc., can solve the problems of easy damage and large internal force response, and achieve the effect of easy replacement, reduction of internal stress, and reduction of internal force and displacement of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

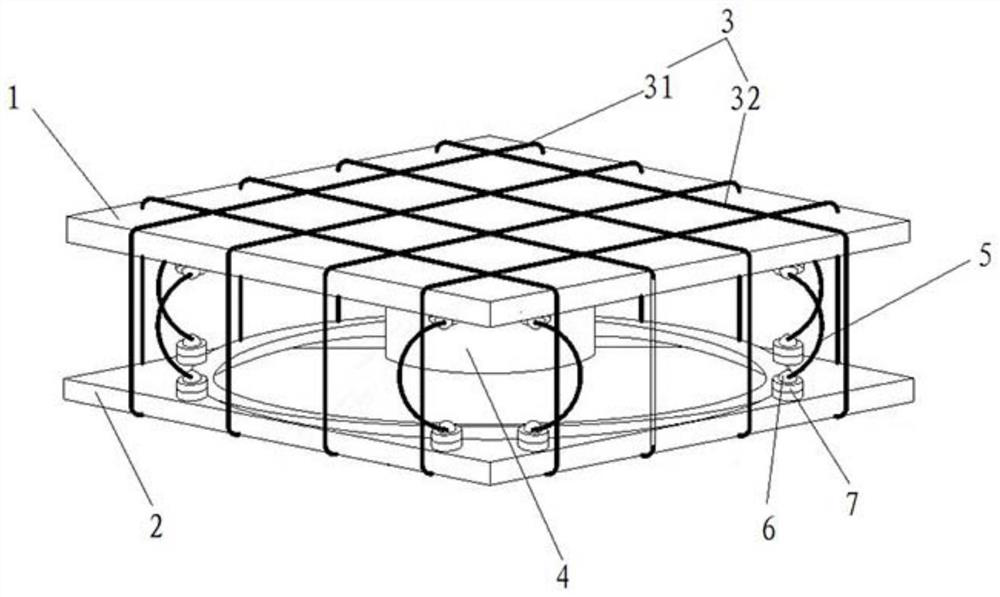

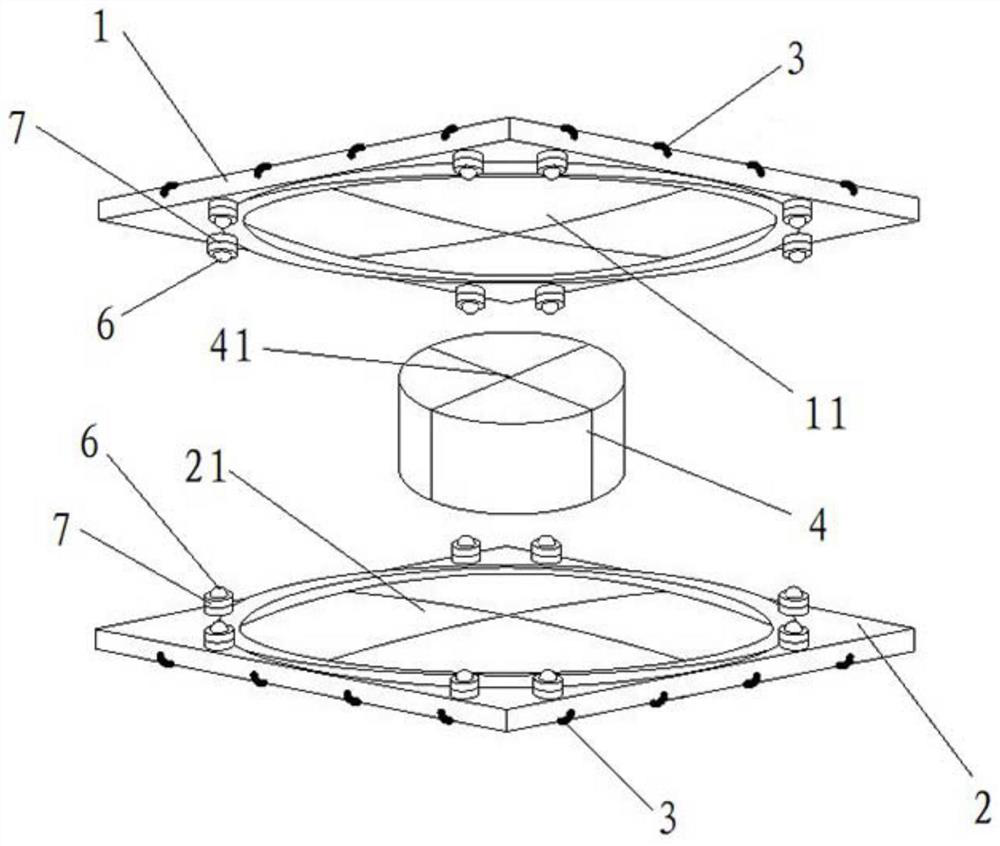

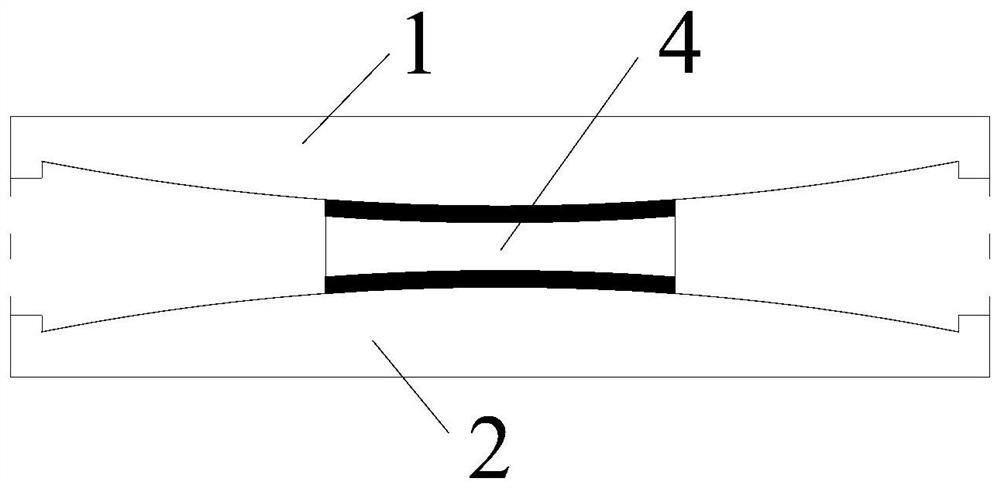

[0032] Specific embodiment one of the SMA negative stiffness damping device of the present invention, as figure 1 , figure 2 As shown, it includes an upper seat plate 1, a lower seat plate 2 and a slider 4 between the upper and lower seat plates, the upper seat plate 1 and the lower seat plate 2 are rectangular plates, and the slider 4 is a columnar structure. The central position of the lower side of the upper seat plate 1 has a lower convex arc surface 11, and the upper side of the lower seat plate 2 has an upper convex arc surface 21, and the edges of the upper convex arc surface 21 and the lower convex arc surface 11 are all circular, and the upper seat plate The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com