Remote water pressure monitoring terminal of smart outdoor fire hydrant, and smart outdoor fire hydrant

A technology for monitoring terminals and fire hydrants, which can be used in measuring devices, fire rescue, water supply devices, etc. It can solve the problems of difficult to achieve reliable and stable data transmission, buried in soil or even concrete, and difficult installation of monitoring devices, etc., to achieve structural installation Convenience, stable and reliable data transmission, convenient and fast maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

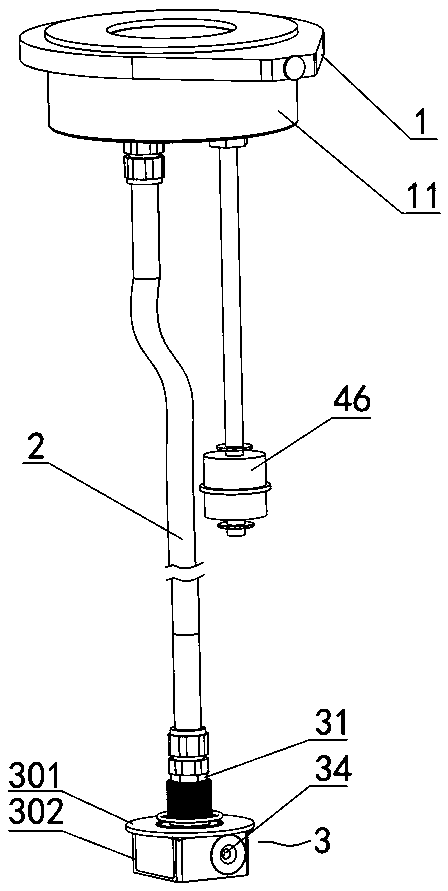

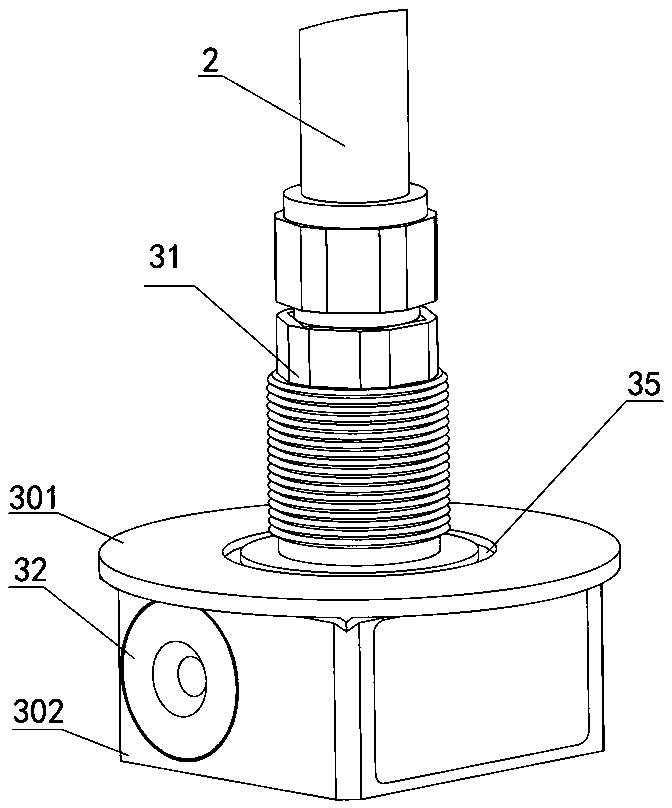

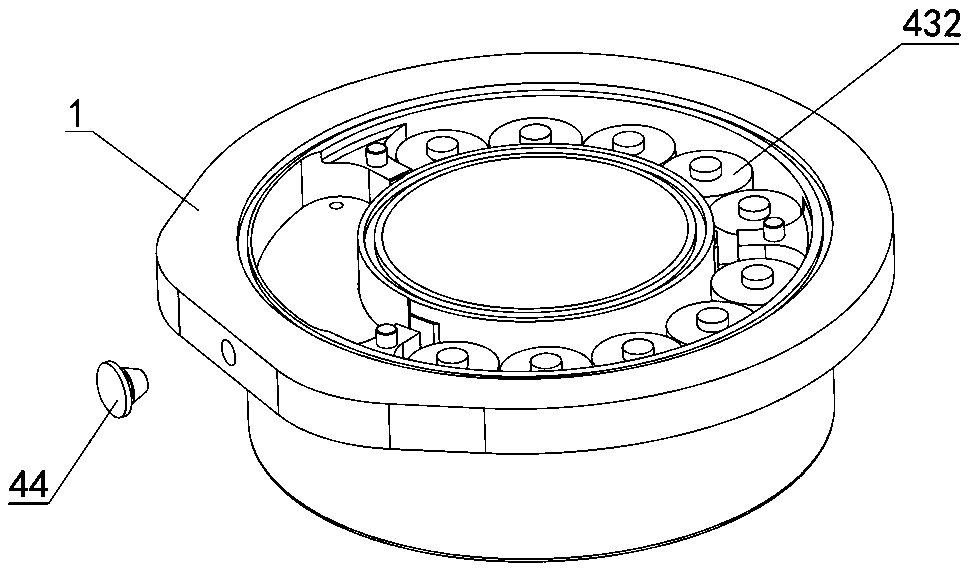

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the intelligent outdoor fire hydrant remote water pressure monitoring terminal of this embodiment includes a monitoring terminal body 1, a protective wire casing 2, and a water pressure detection probe 3 connected in sequence. The monitoring terminal body 1 is provided with a control unit 4, and the monitoring terminal body 1. The middle part is provided with a through hole and the bottom is provided with a mounting seat 11 for inserting into the opening at the top of the fire hydrant. The top of the water pressure detection probe 3 is provided with a mounting post 31 for the through hole installed on the fire hydrant valve core. The detection probe 3 is provided with a pressure sensor unit 32 , and the cable of the pressure sensor unit 32 is electrically connected to the control unit 4 after being passed through the inner hole of the installation column 31 through the sealed protective wire sleeve 2 . ...

Embodiment 2

[0052] The remote water pressure monitoring terminal of the intelligent outdoor fire hydrant in this embodiment is basically the same as the first embodiment, and the main difference is that the remote water pressure monitoring terminal of the intelligent outdoor fire hydrant in this embodiment is an integrated structure with the locking cover of the fire hydrant. Therefore no additional locking cover is required, see Image 6 In order to achieve an integrated structure with the locking cover of the fire hydrant, in this embodiment, the monitoring terminal body 1 is also provided with an installation through hole 12 for installing to the fire hydrant, and the middle part of the monitoring terminal body 1 is provided with an operating lever for installing the fire hydrant. The first threaded hole 13. Through the integrated structure of the locking cover of the fire hydrant, the remote water pressure monitoring terminal of the intelligent outdoor fire hydrant in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com