Contact spot and transmission error comprehensive test bench for transmission assembly

A technology of contact spots and transmission errors, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve problems such as untrue measurement values of transmission errors, poor contact state of gears, and low testing efficiency, etc., to achieve The effect of avoiding the influence of measurement results and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

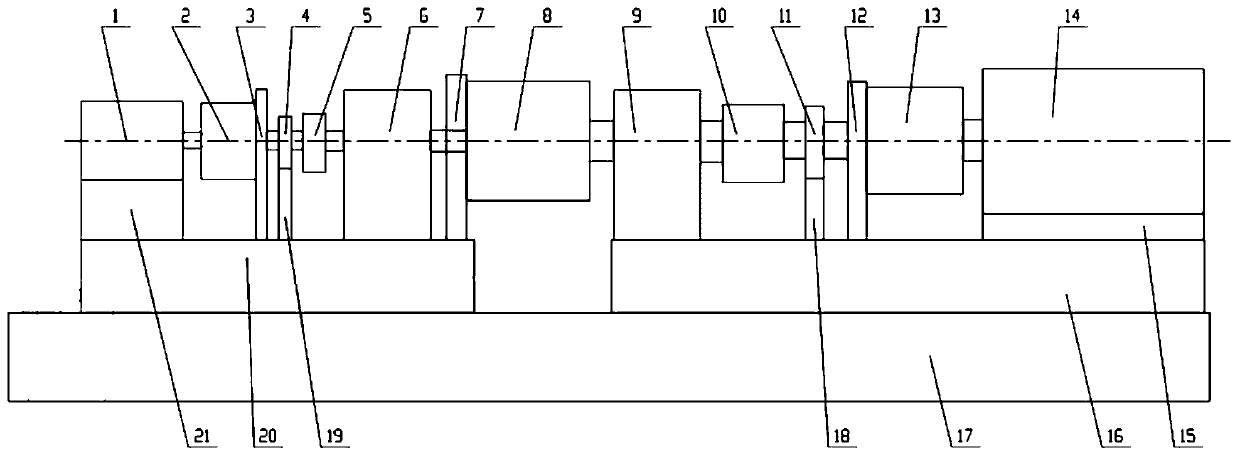

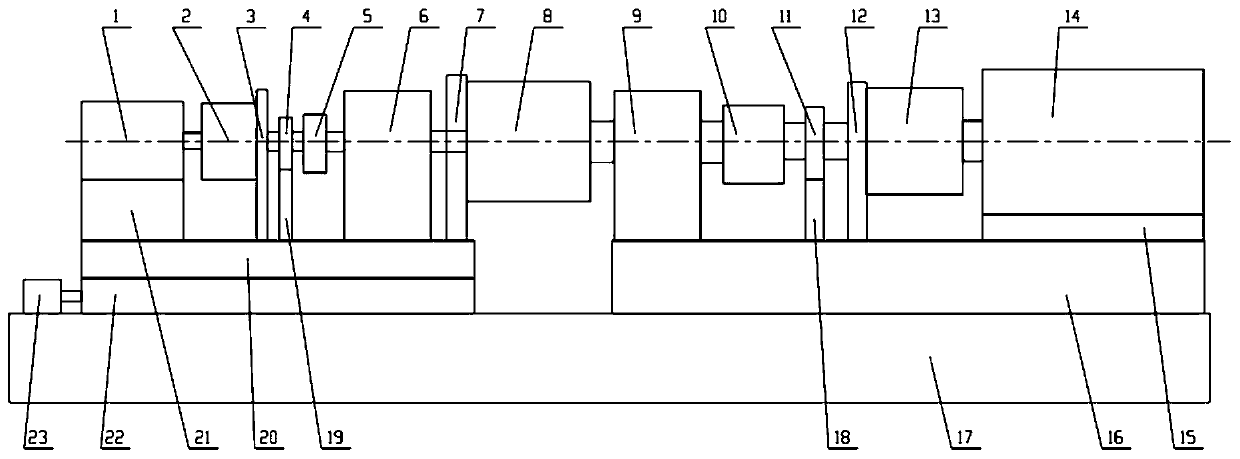

[0028] This embodiment provides a high-precision transmission assembly contact spot and transmission error comprehensive test bench capable of carrying out two tests of contact spot test and transmission error test.

[0029] Such as figure 1 As shown, the test bench includes: a table body 17, a driving assembly and a loading assembly, wherein the table body 17 is used as a supporting platform for deflecting the slide plate 22, the angle misalignment adjustment mechanism 23, carrying the driving assembly and the loading assembly.

[0030] The drive assembly includes: a drive motor 1 , a drive end reducer 2 , a drive headstock assembly 6 and a drive slide 20 . Let the axial direction of the driving assembly be the longitudinal direction, and the direction perpendicular to the longitudinal direction on the support surface of the table body 17 be the transverse direction. The driving slide 20 is installed on the table body 17 through the transverse guide rail, and the drive slide...

Embodiment 2

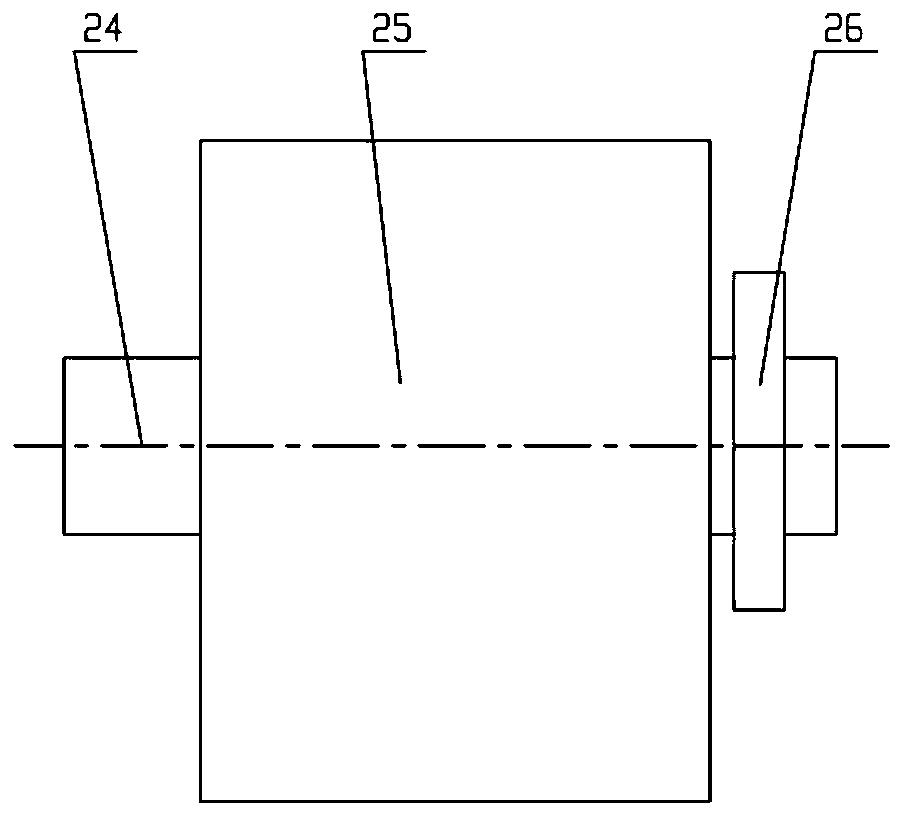

[0046] A pair of involute gears with ideal shape and infinite rigidity are meshed, and the rotation angle of the driven gear will be consistent with that of the driving gear strictly according to the speed ratio of the two. However, in fact, due to the existence of errors such as gear manufacturing errors, assembly errors, transmission system load deformation, and gear tooth deformation under load, the driven gear rotation angle will lead or lag behind its theoretical rotation angle position at different times, that is, the gear transmission error. In the transmission error test, in order to be closer to the actual working conditions of the gear, on the basis of the above-mentioned embodiment 1, an angle misalignment adjustment assembly is further added to the test bench for the transmission with misaligned meshing gear pairs to be tested. Item 8 is a test for passing errors.

[0047] Such as image 3 As shown, the angle misalignment adjustment assembly includes: a deflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com