Hierarchical grouping collaborative optimization scheduling method for retired power battery groups

A power battery pack and power battery technology, applied in the field of energy storage, can solve problems such as the difficulty in accurately managing single batteries, excessive use of battery packs, and insufficient use of battery packs, so as to improve utilization and economy, and reduce scheduling complexity degree, to avoid the effect of overuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

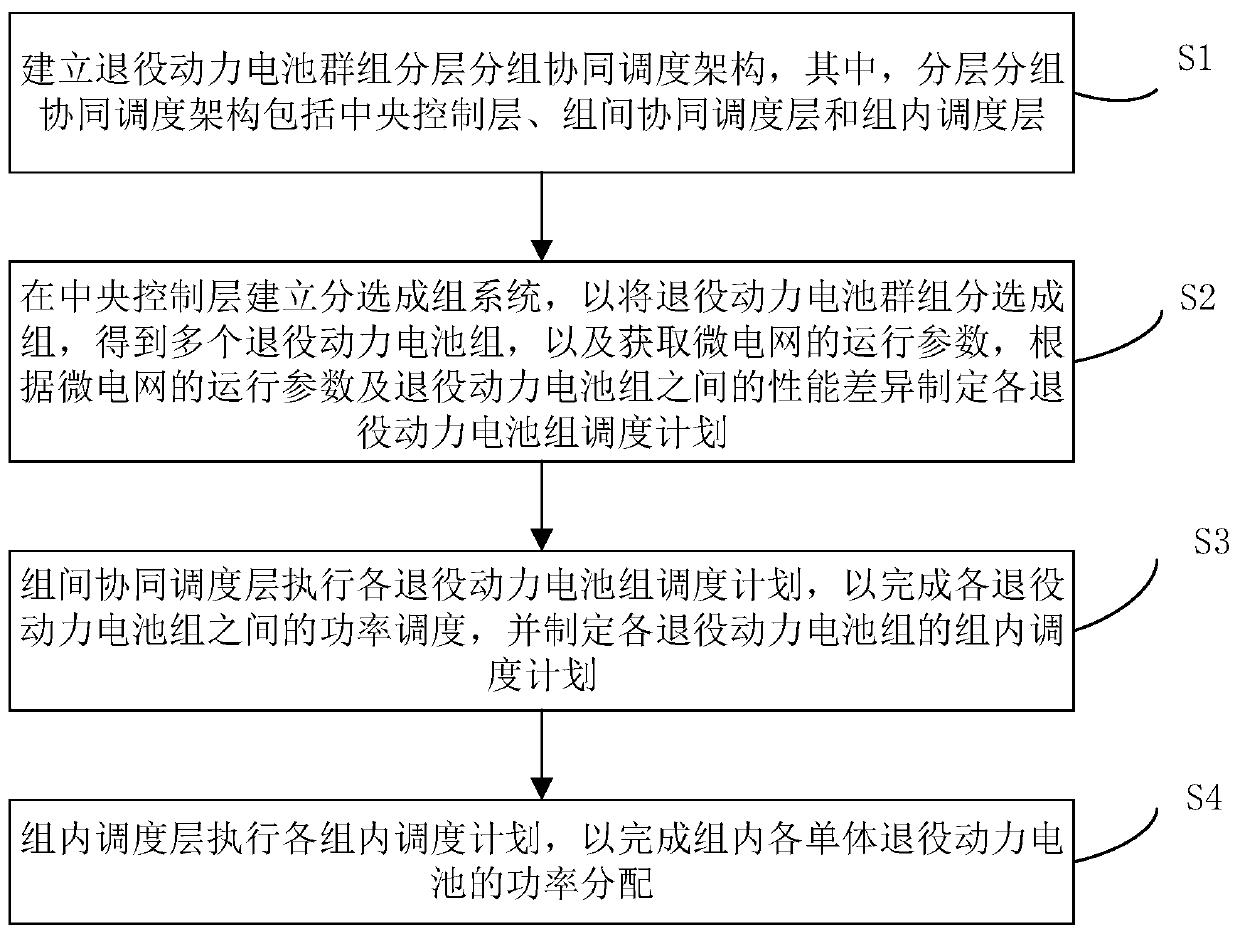

[0045] figure 1 It is a flowchart of a hierarchical grouping cooperative optimization scheduling method for decommissioned power battery groups according to an embodiment of the present invention. Such as figure 1 As shown, the collaborative optimization scheduling method includes the following steps:

[0046] S1. Establish a hierarchical group collaborative scheduling framework for decommissioned power battery groups, wherein the hierarchical group collaborative scheduling framework includes a central control layer, an inter-group collaborative scheduling layer, and an intra-group scheduling layer.

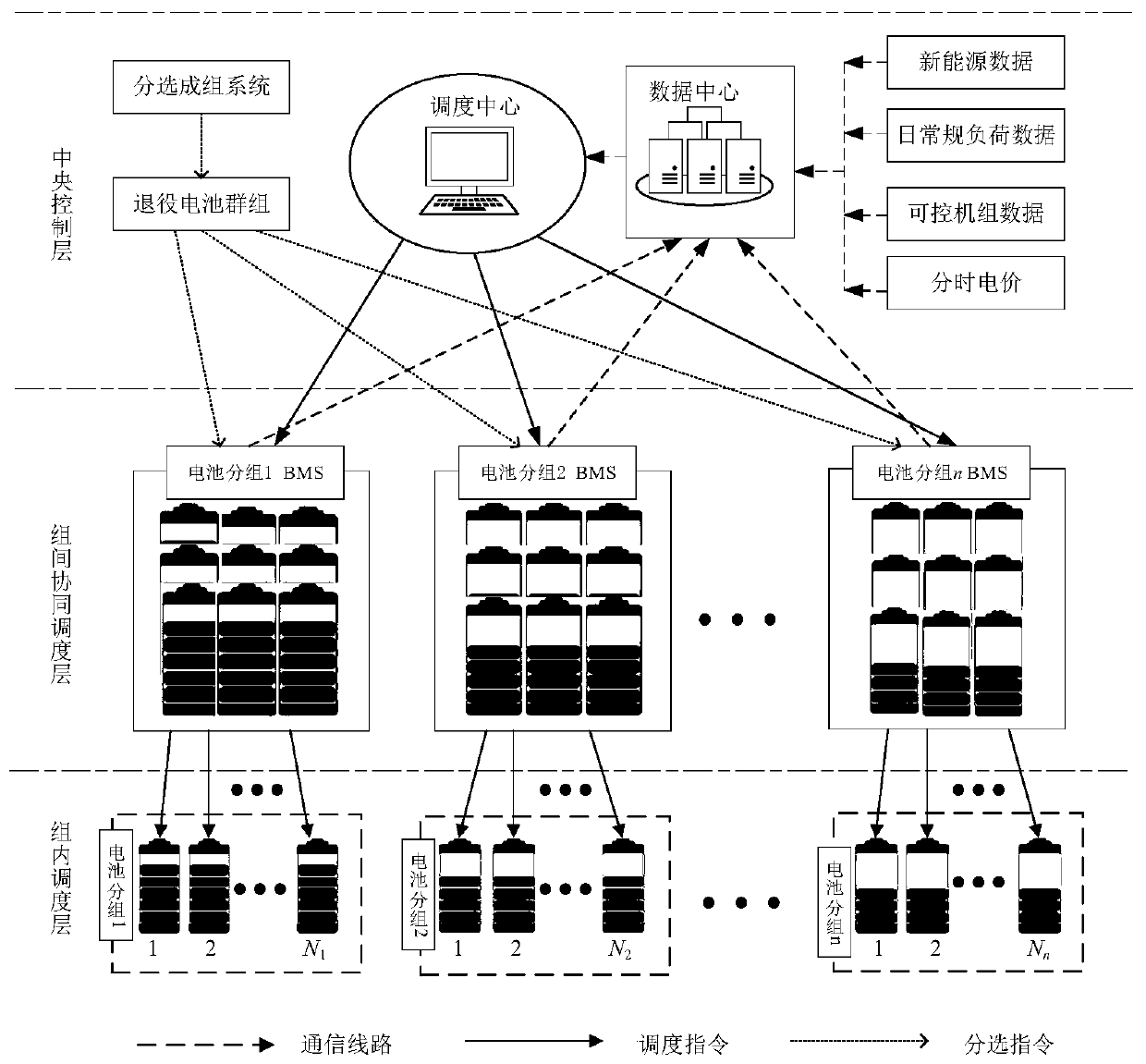

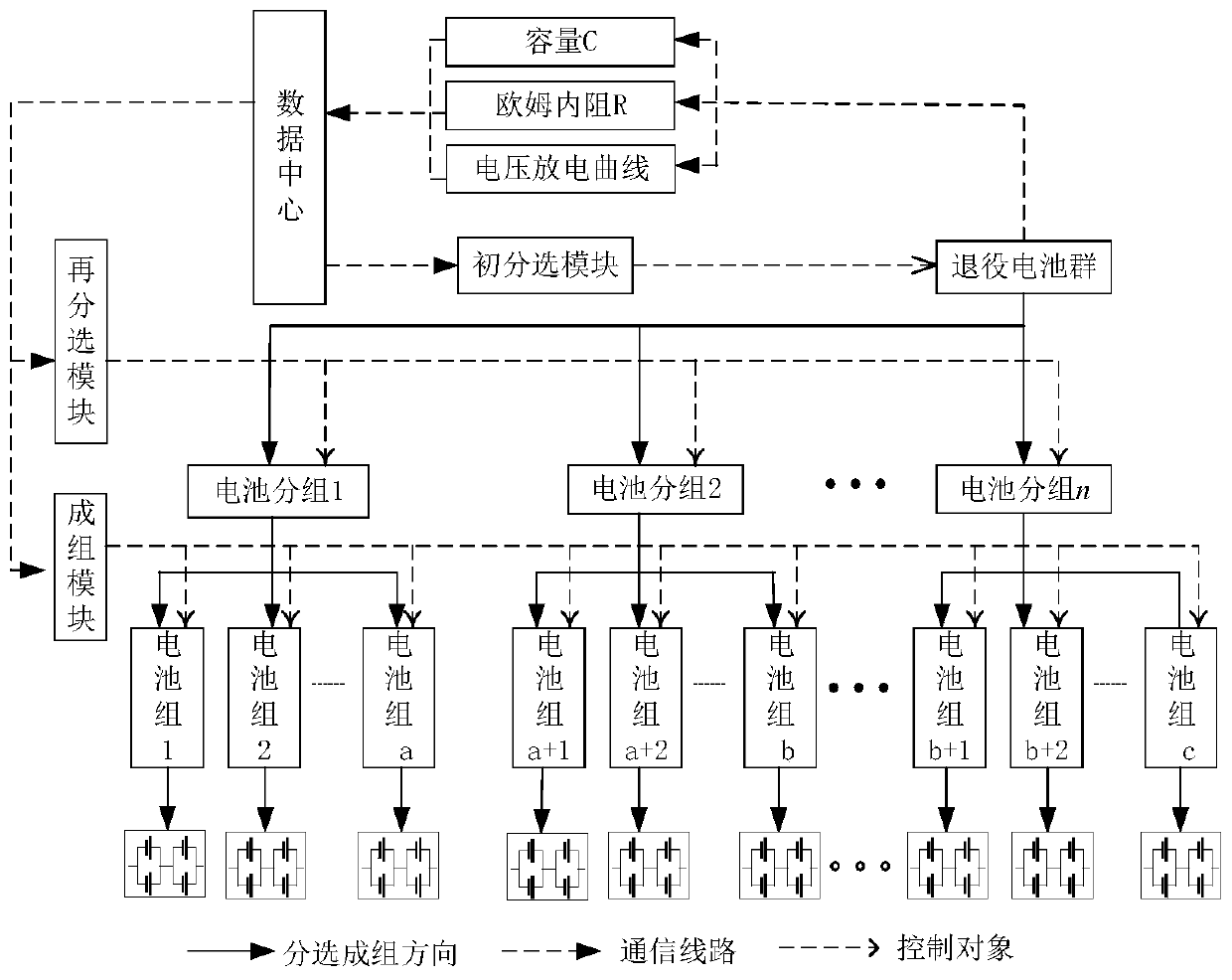

[0047] Specifically, such as figure 2 As shown, the top layer of the group-by-layer cooperative scheduling architecture for decommissioned power battery groups is the central control layer, which is responsible for sorting and dispatching decommissioned power battery groups into groups and issuing dispatching instructions. The dispatching object is each decommissioned power ba...

Embodiment 2

[0098] The invention also proposes a computer-readable storage medium.

[0099] In an embodiment of the present invention, a computer program is stored on a computer-readable storage medium, and when the computer program is executed by a processor, the above-mentioned hierarchical grouping cooperative optimization scheduling method for decommissioned power battery groups is implemented.

[0100] In the computer-readable storage medium of the embodiment of the present invention, when the computer program corresponding to the above-mentioned layered grouping cooperative optimization scheduling method for decommissioned power battery groups stored thereon is executed by a processor, the decommissioned power battery groups can be arranged layer by layer Decomposition, reducing the scale of scheduling objects at each layer, reducing the complexity of scheduling, and further reducing the complexity of scheduling by improving the consistency of the performance of decommissioned power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com