Processing tool applied after stamping processing of an automobile parts

A technology for auto parts and stamping processing, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of no oil-immersed structure, affecting use, easy to form pollution, etc., and achieve the effect of regular operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

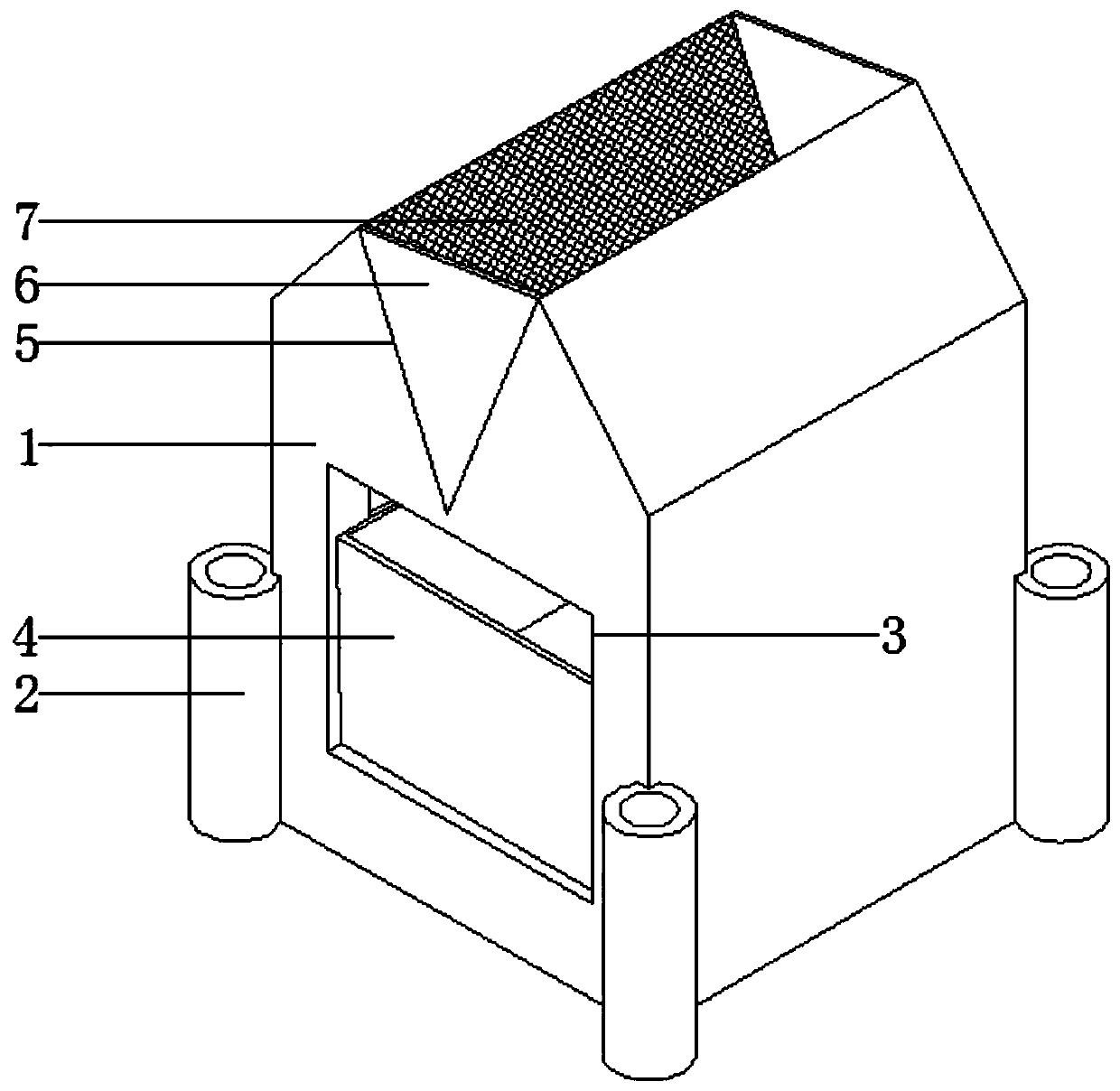

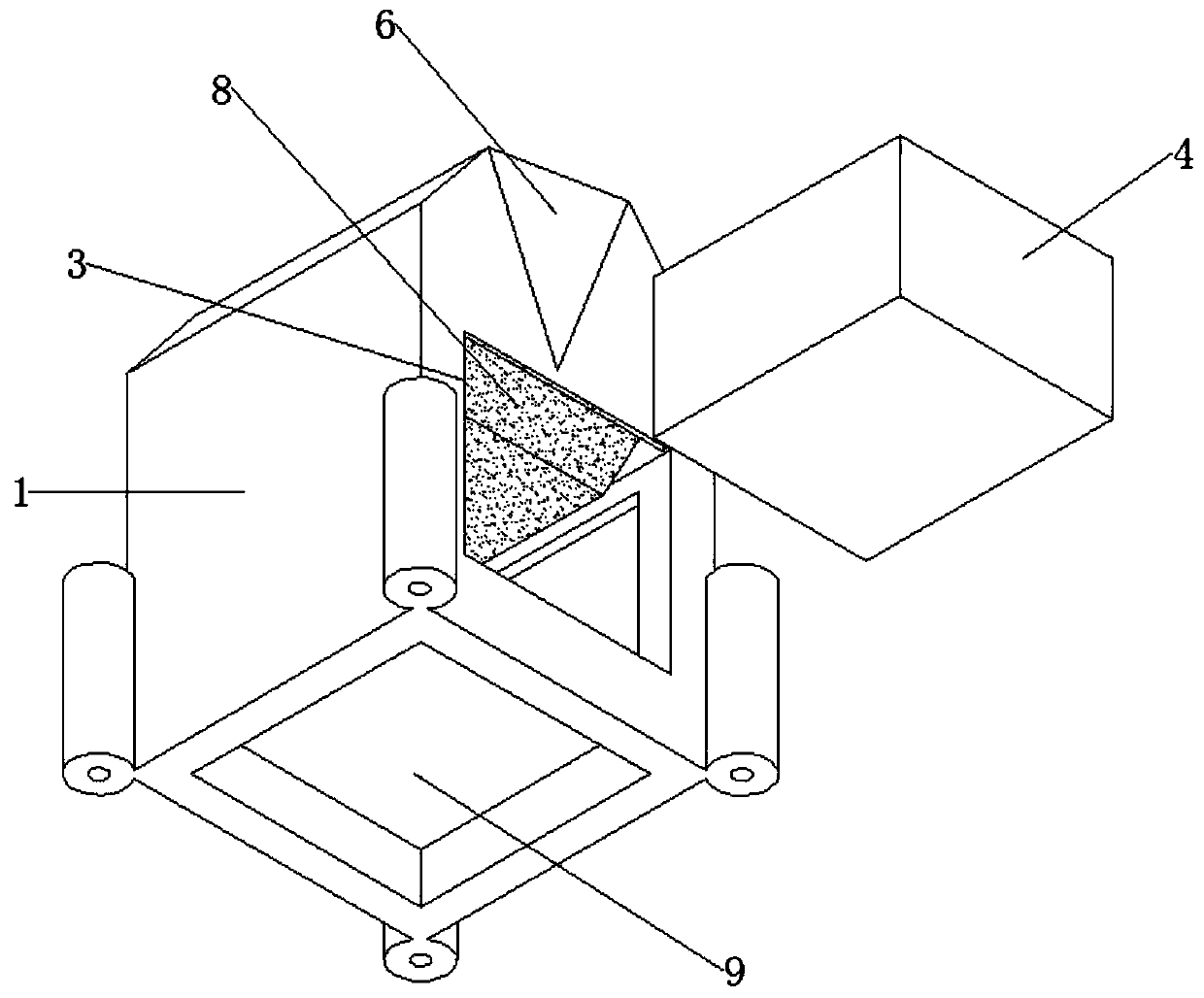

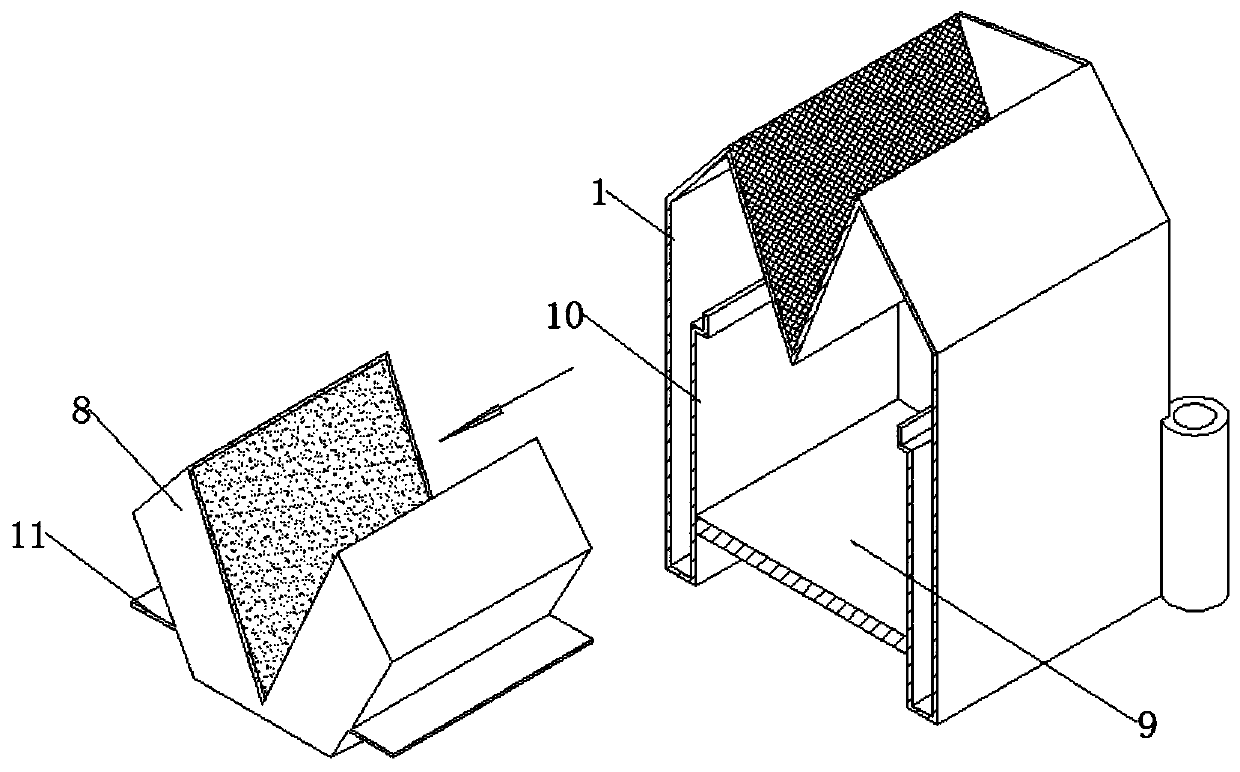

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides a tooling for processing auto parts after stamping, including a tooling body 1, a mounting column 2, a storage tank 3, a connecting tank 4, a V-shaped groove 5, a V-shaped plate 6, a dipping hole 7, and a dipping seat 8 , a bottom support plate 9, an inner support structure 10 and a side support plate 11; the tooling body 1 is a rectangular three-dimensional cavity structure, and its front side is inwardly provided with a storage bilge 3 of a square groove structure, and the storage bilge 3 The bottom of the bilge has a bottom brace 9; the storage bilge 3 is placed with a connecting compartment 4 of a rectangular cabin structure; the installation column 2 is four places, and they are evenly distributed and fused on the four vertical corners of the tooling body 1 , and the mounting column 2 is a stepped mounting hole, which is used to fix the device on the machining platform; the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com