Slope form gravity type falling channel system for automatic sorting system

An automatic sorting system and sorting system technology, applied in the field of mechanical structures, can solve problems such as low efficiency, damage to items and electric control doors, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

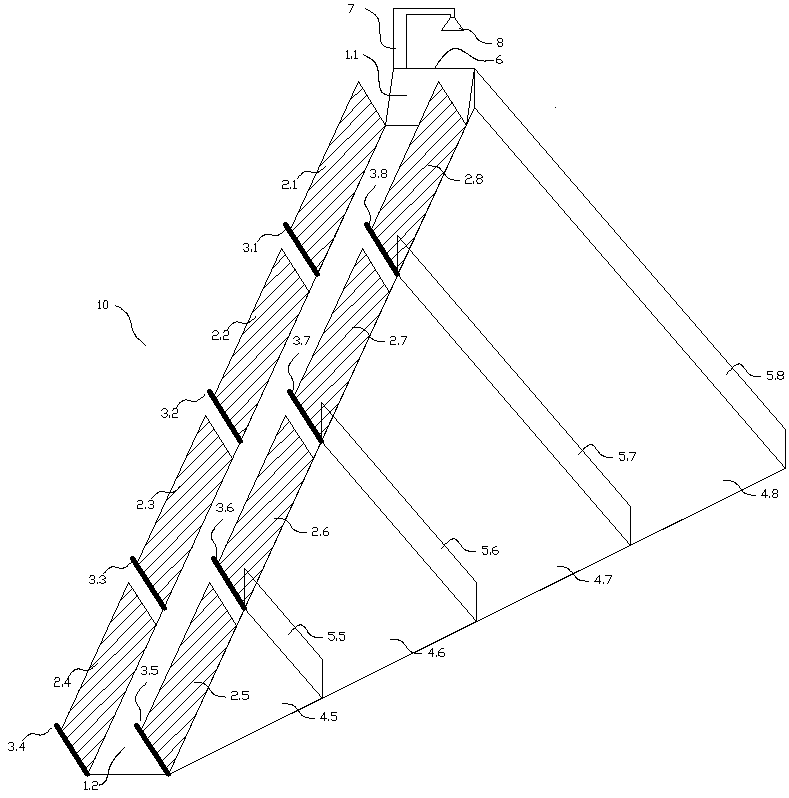

[0058] Such as figure 1 As shown, the body of the sorting system (10) mainly includes a slope (1) as a drop channel and an electric control gate (2) arranged on the side of the slope. The electric control door (2) is a rotary electric control door (2), and the axis of the drive shaft (3) is perpendicular to the upper surface of the slope (1).

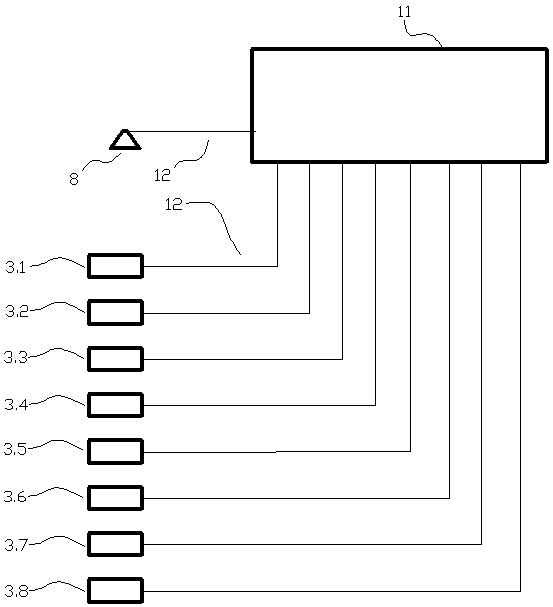

[0059] Such as figure 2As shown, the scanner (8) and the drive shaft (3) are connected to the electric control system (11) through wires (12).

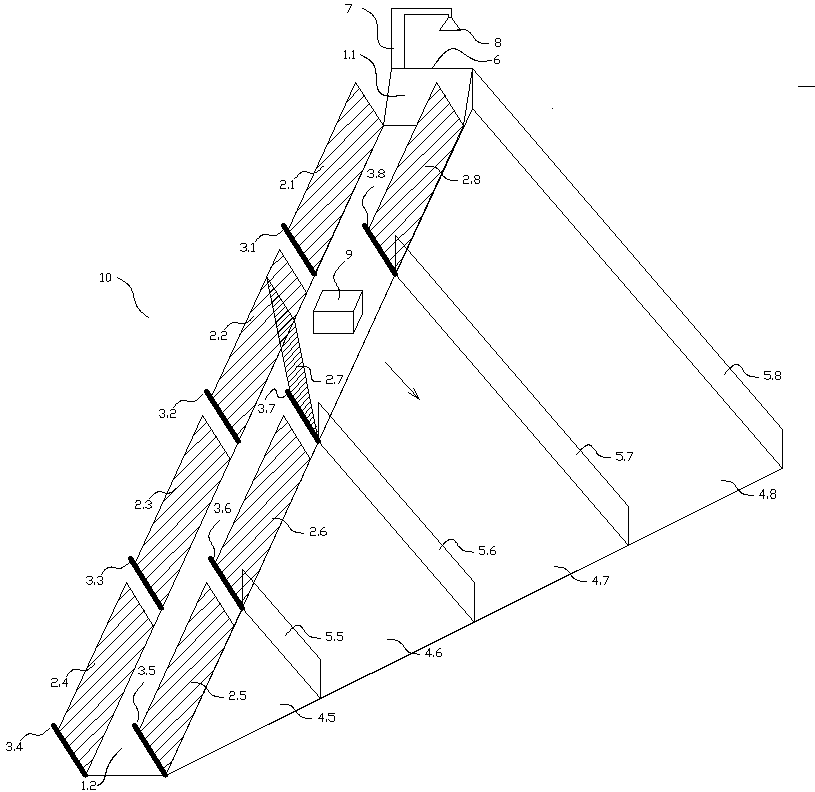

[0060] Such as Figure 4 As shown, after being scanned by the barcode scanner (8), the sorted items (9) enter the slope (1) as a drop channel from the entrance (6) of the slope (1), and fall along the slope (1). The electronic control system (11) instructs the corresponding electric control door (2.7) to open according to the information of the item (9) scanned by the scanner (8). When the item (9) falls to the electric control door (2.7), the Under the action of the electric control door...

Embodiment 2

[0062] Such as Figure 5 As shown, the body of the sorting system (10) mainly includes a slope (1) as a drop channel and an electric control door (2) arranged on the slope surface. The electric control door (2) is a rotary electric control door (2), and the rotating shaft (3) of the electric control door is parallel to the surface of the slope (1). The electrically controlled gate (2) is an integral part of the ramp (1).

[0063] Such as Figure 6 As shown, the scanner (8) and the motor system (10) are connected with the electric control system (13) through wires (12).

[0064] Such as Figure 8 As shown, after being scanned by the barcode scanner (8), the sorted items (9) enter the slope (1) as a drop channel from the entrance (6) of the slope (1), and fall along the slope (1). The electronic control system (13) instructs the corresponding electric control gate (2.1) to turn right according to the information of the item (9) scanned by the scanner (8), so that the item sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com