Steel coil packaging auxiliary control system and method based on internet of things

An auxiliary control system and technology of the Internet of Things, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problem of automatically adjusting the number of strapping belts, inaccurate steel coil weighing readings, and missing two bundles of thick specifications. problems, to avoid the measurement of objection, reduce the amount of objection compensation, and improve the technical level of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

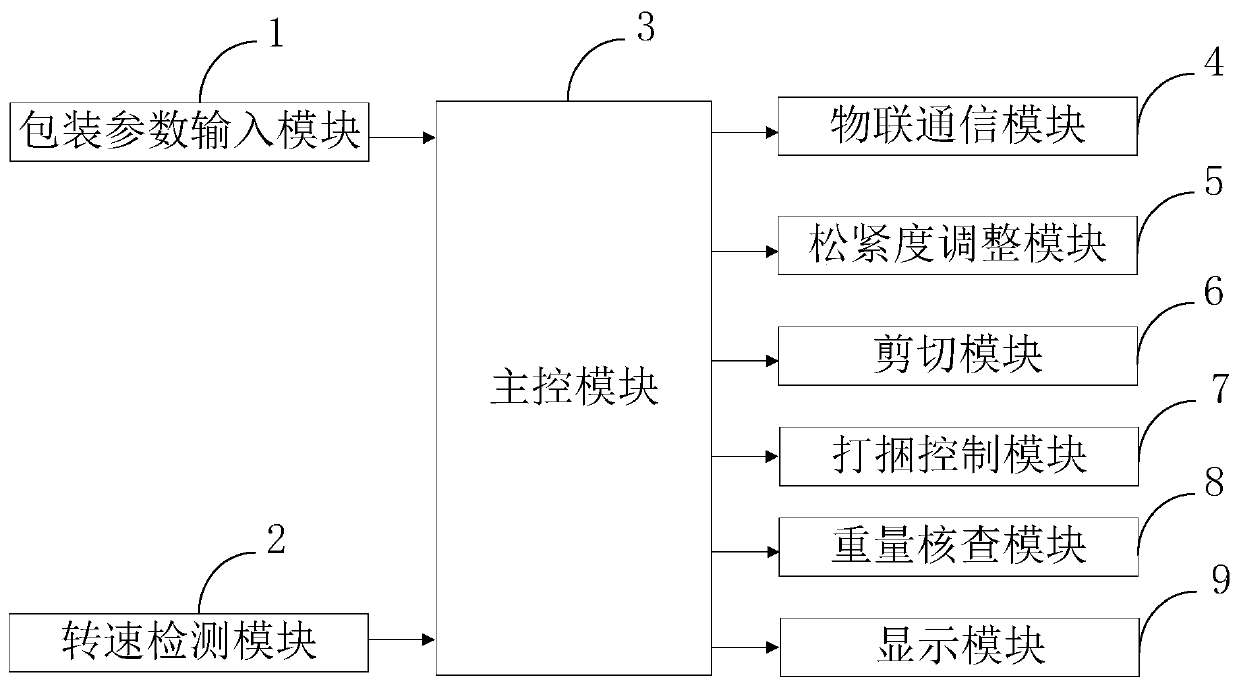

[0043] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0044] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

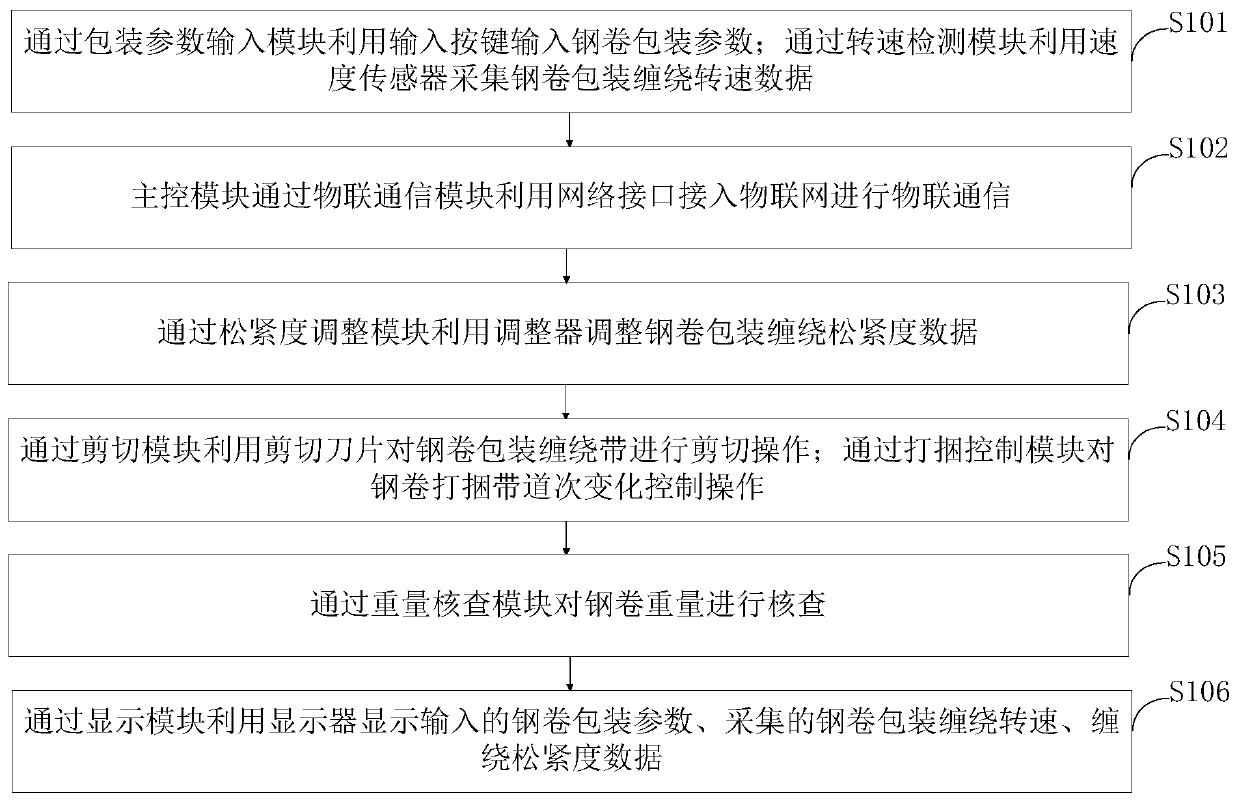

[0045] Such as figure 1 As shown, the auxiliary control method for steel coil packaging based on the Internet of Things provided by the present invention includes the following steps:

[0046]Step S101, using the input button to input steel coil packaging parameters through the packaging parameter input module; using the speed sensor to collect steel coil packaging winding speed data through the speed detection module;

[0047] Step S102, the main control module connects to the Internet of Things through the Internet of Things communication module to perform Internet of Things communication;

[0048] Step S103, using the adjuster t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com