Laser welding process parameter optimization method based on Bagging integrated prediction model and particle swarm optimization algorithm

A technology of process parameter optimization and particle swarm optimization, applied in laser welding equipment, welding equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

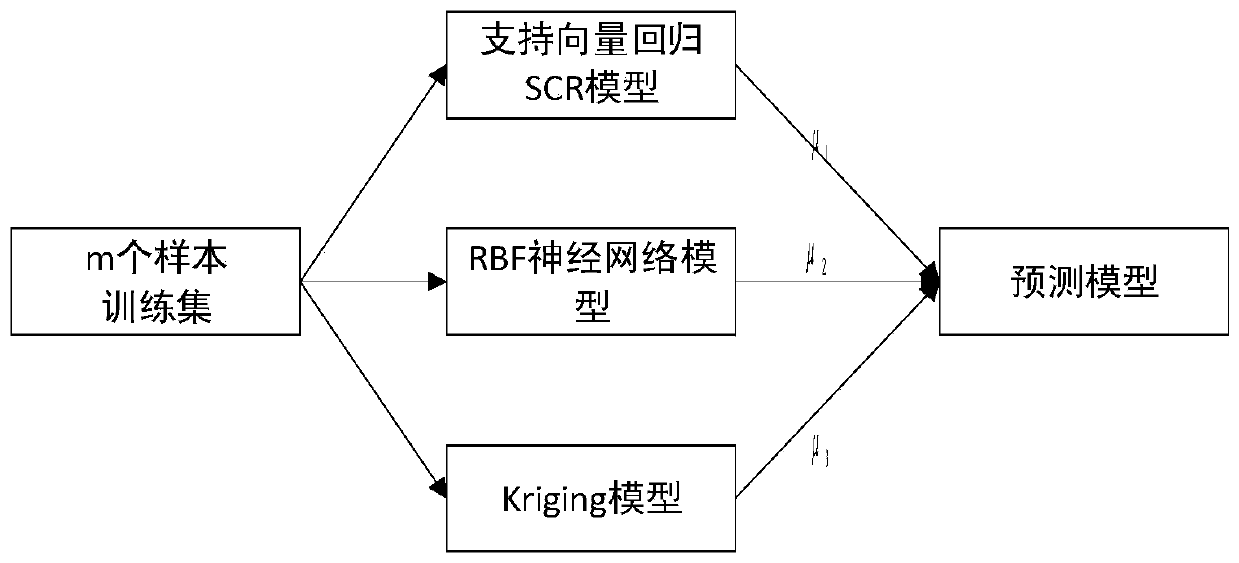

[0051] A Bagging algorithm to integrate multiple base learners into a new prediction model, including the following steps:

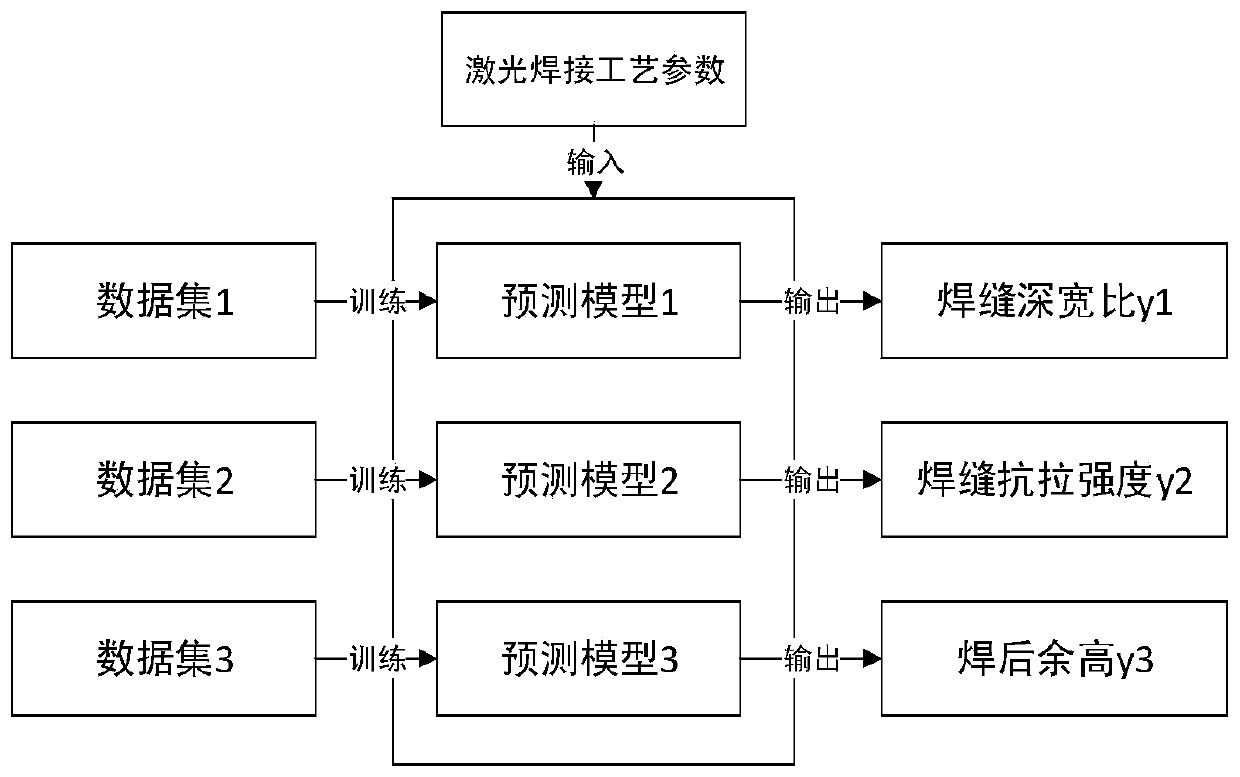

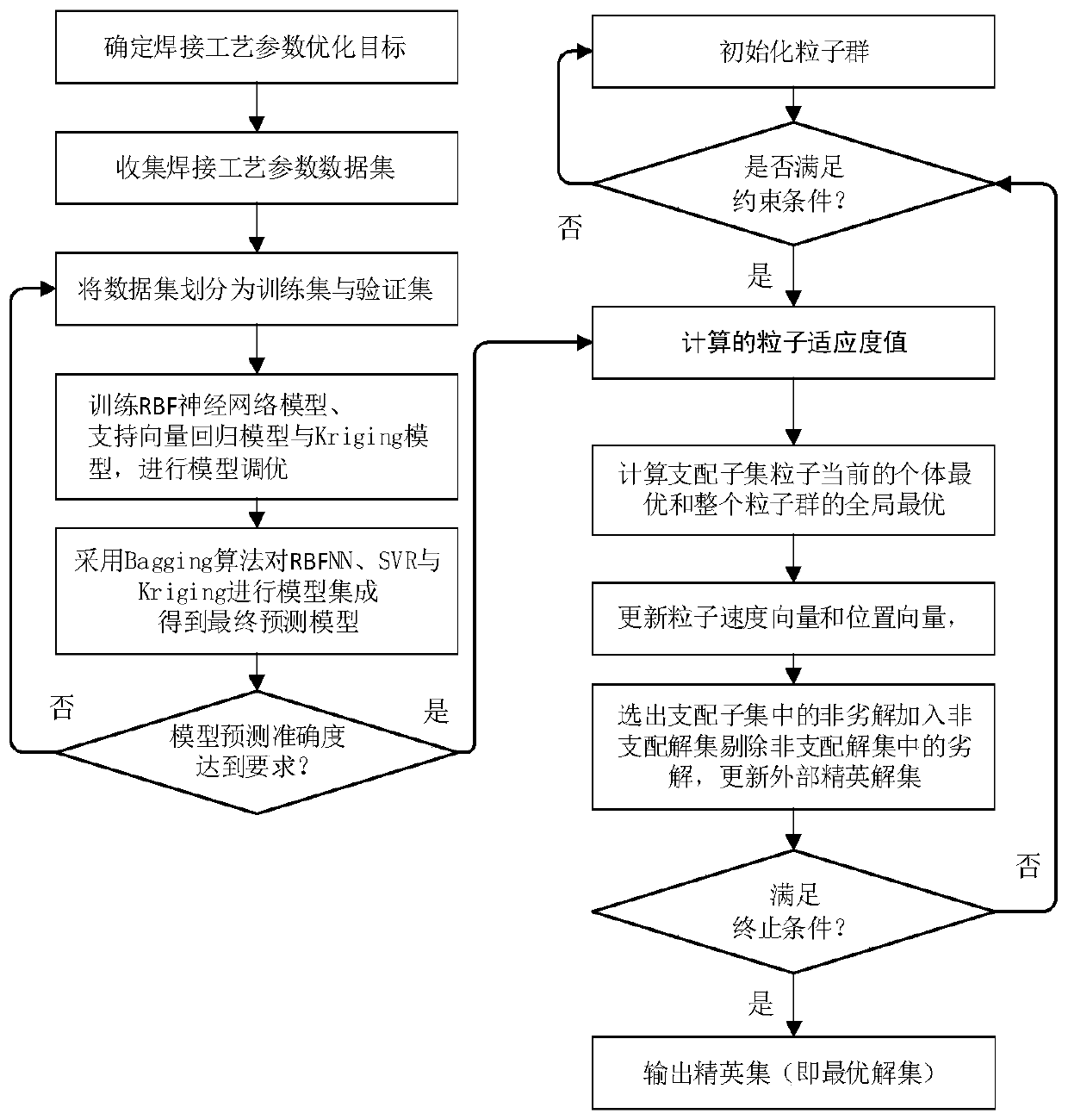

[0052] Determine the optimization target of laser welding process parameters. Laser welding process parameters include laser power (LaserPower, LP), welding speed (Welding Speed, WP), defocusing amount (Defocusing Amount, DA), laser pulse width (Laser Pulse Width, LPW) ; Welding quality evaluation parameters include weld depth-width ratio, weld tensile strength, weld reinforcement; where, weld depth-width ratio is DW=DP / BW, DP is weld pool depth, BW is weld fusion Pool width, weld tensile strength is TS=F max / S,F max is the maximum tensile stress of the weld, S is the effective cross-sectional area of the weld, and H is the weld reinforcement. The optimization goal is to select reasonable laser welding process parameters (laser power, welding speed, defocus amount, and laser pulse width) to perform the welding task to obtain the largest weld depth-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com