A post-pouring tape waterproof structure and its construction method

A technology of waterproof structure and post-cast tape, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of ignoring post-cast tape waterproof construction and only paying attention to exterior walls, etc., to improve practicability and convenience , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

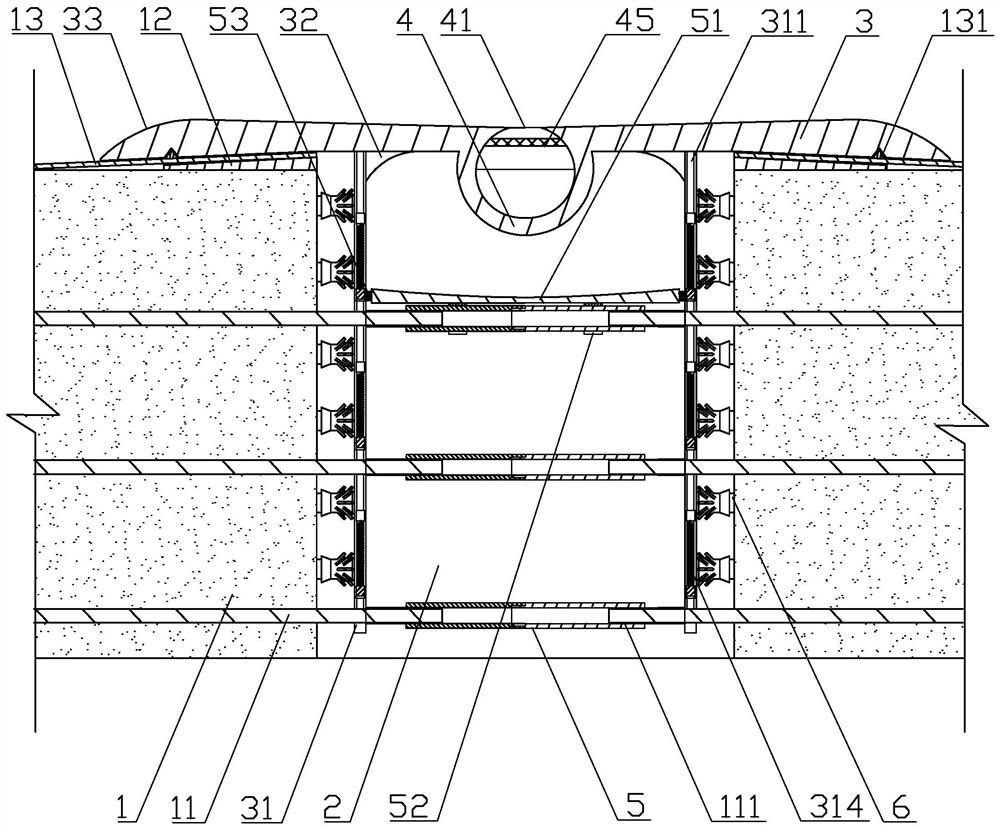

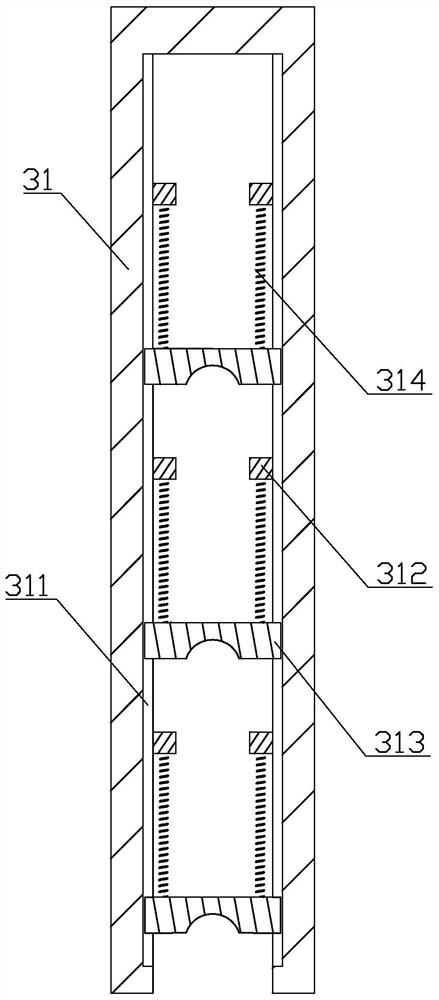

[0044] Embodiment 1: as figure 1 As shown, a post-cast belt waterproof structure includes a belt body 2 arranged between adjacent substrates 1, the substrate 1 is formed by pouring concrete, and a plurality of end-to-end spliced protective plates 3 are placed on the upper surface of the substrate 1 to protect The plate 3 is used to cover the strip body 2 so as to prevent moisture from entering the strip body 2 .

[0045] A plurality of steel bars 11 are laid in the matrix 1 , and one end of the steel bars 11 extends into the belt body 2 , and the steel bars 11 on both sides of the belt body 2 correspond one by one. The surface of the exposed steel bar 11 is covered with a waterproof membrane 111, which is used to protect the steel bar 11 and avoid corrosion of the steel bar 11 exposed to the air for a long time; a sleeve 5 is arranged between the opposite steel bars 11, and the sleeve 5 is two-stage. The connection between the two sections of sleeves 5 is realized through s...

Embodiment 2

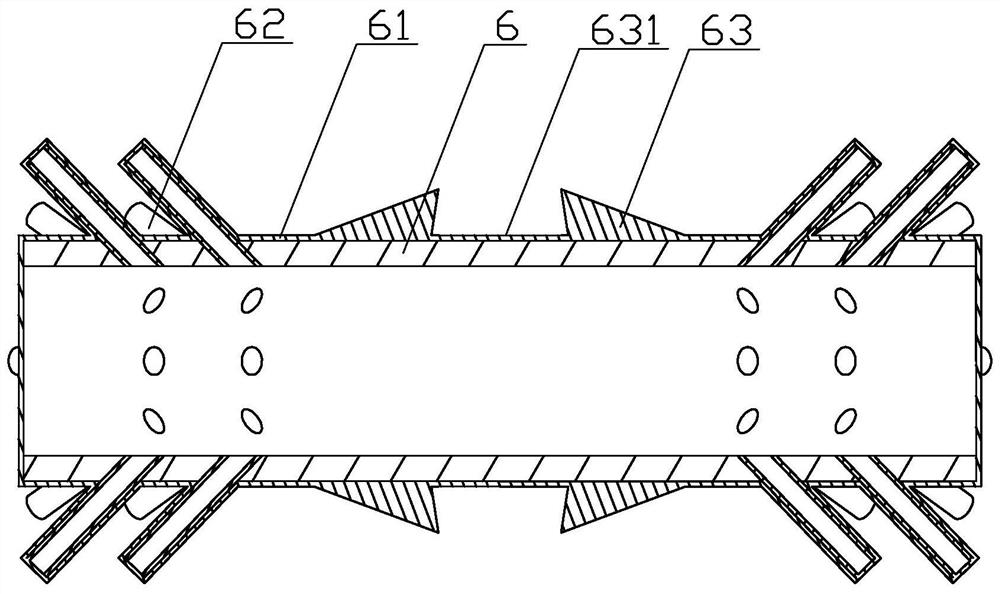

[0054] Embodiment 2: as figure 1 , figure 2 Shown is a post-cast waterproof structure. The difference between this embodiment and Embodiment 1 is that in this embodiment, the shell 61 is made of non-toxic AS resin. AS resin is a polymer compound formed by the copolymerization of acrylonitrile and styrene. It has excellent solvent resistance and good load bearing capacity. It is not easy to be damaged during concrete pouring, so as to avoid the shell 61 cracking and affecting the post-casting belt. pouring.

Embodiment 3

[0055] Embodiment 3: as figure 1 , figure 2 As shown, a post-cast waterproof structure, the difference between this embodiment and embodiment 1 is that in this embodiment, the shell 61 includes three layers, the outer layer is made of non-toxic AS resin, and its excellent solvent resistance The outer shell 61 can be prevented from decomposing when encountering water; the middle layer is made of ABS plastic, so as to increase the strength and toughness of the pouring pipe 6, and can effectively prevent concrete from breaking into the pouring pipe 6; the inner layer is made of non-toxic PS plastic. PS plastic refers to a class of plastics including styrene base in the macromolecular chain, including styrene and its copolymers. Specific varieties include general-purpose polystyrene (GPPS), high-impact polystyrene (HIPS), expandable Polystyrene (EPS) and metallocene polystyrene (SPS), etc. In this embodiment, general-purpose polystyrene is selected, and its melting temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com