A large-scale equipment installation and main structure reverse calculation and construction method

A main structure, large-scale equipment technology, applied in building structure, formwork/formwork/work frame, on-site preparation of building components, etc., can solve the problems of high installation cost, affecting construction period, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

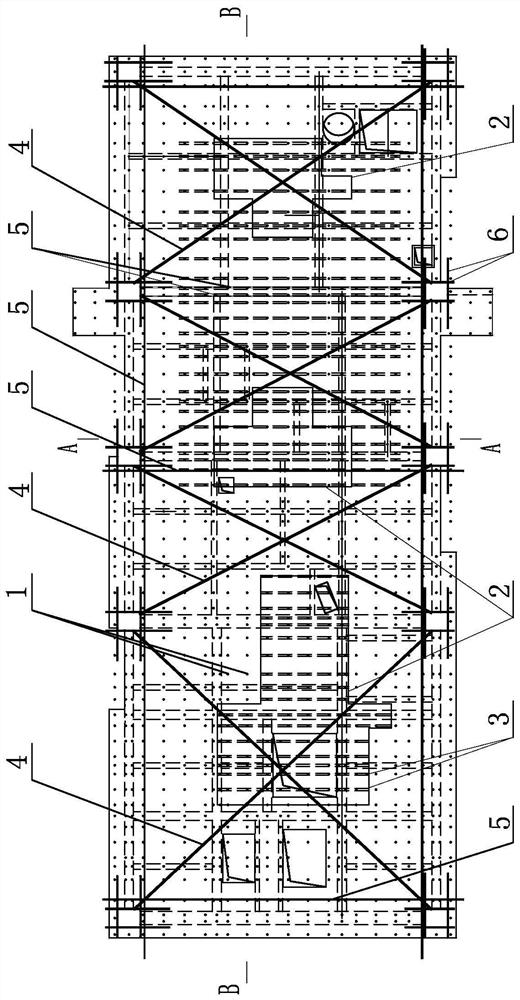

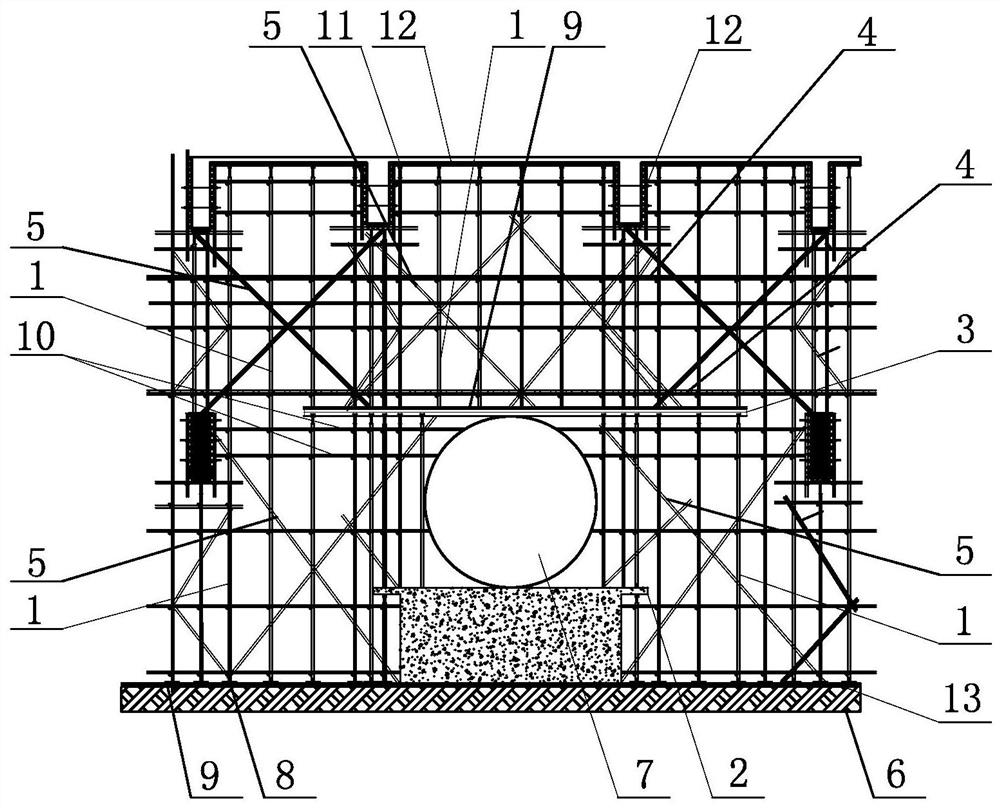

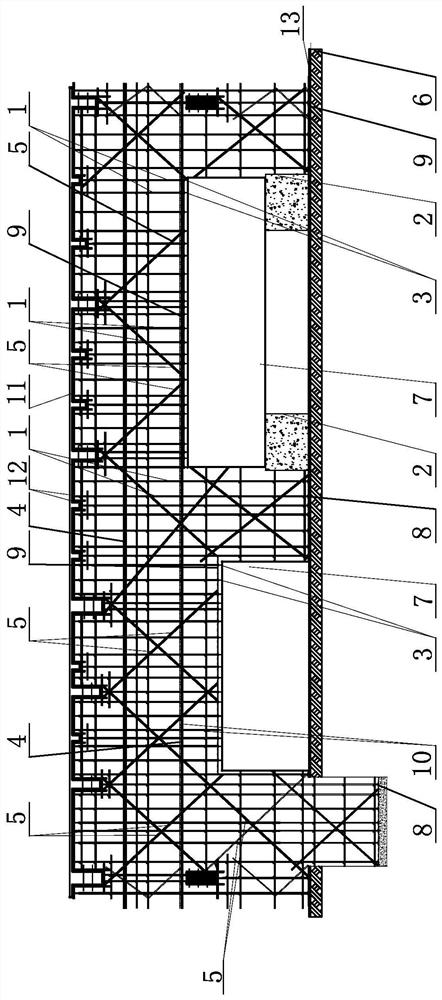

[0068]The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0069]Such asFigure 1-Figure 3As shown, the large-scale equipment installation and main structure reverse calculation and construction method of the present invention:

[0070]1. Formwork support system check calculation

[0071]1) Calculation of the axial force of the upright rod on the hollow I-beam

[0072]a. Calculation of design value of uniform load on panel

[0073]According to the "Uniform Standard for Reliability Design of Building Structures" GB50068-2018 and the following formula (1-1), the design value of the panel uniform load is calculated.

[0074]q=[γG(G2K×h+G3k×h+G1k)+γQ×Q1k]×b (1-1)

[0075]Among them, q—design value of uniformly distributed load on panel (kN)

[0076]γG—The partial coefficient of permanent load, which is taken as 1.3;

[0077]γQ-Variable load sub-factor, taking 1.5;

[0078]G2k—The weight of the newly poured concrete (kN / m3), which is 24kN / m3;

[0079]G1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com