Flat supporting bracket for assembly type prefabricated superimposed plate construction and construction method for flat supporting bracket

A laminated board, prefabricated technology, applied in formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problem of inability to take advantage of prefabricated structure construction cost, construction period and construction convenience, violation of assembly The installation of the structure is efficient and convenient, without getting rid of the dependence of the vertical support, etc., to achieve the effect of convenient and fast installation and removal, shorten the construction period, and avoid the erection and disassembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] Unless otherwise defined, all technical terms and scientific terms used herein have the same meaning as commonly understood by those skilled in the technical field of the present invention, and the terms used in the description of the present invention herein are only to describe specific implementations The purpose of the example is not intended to limit the present invention.

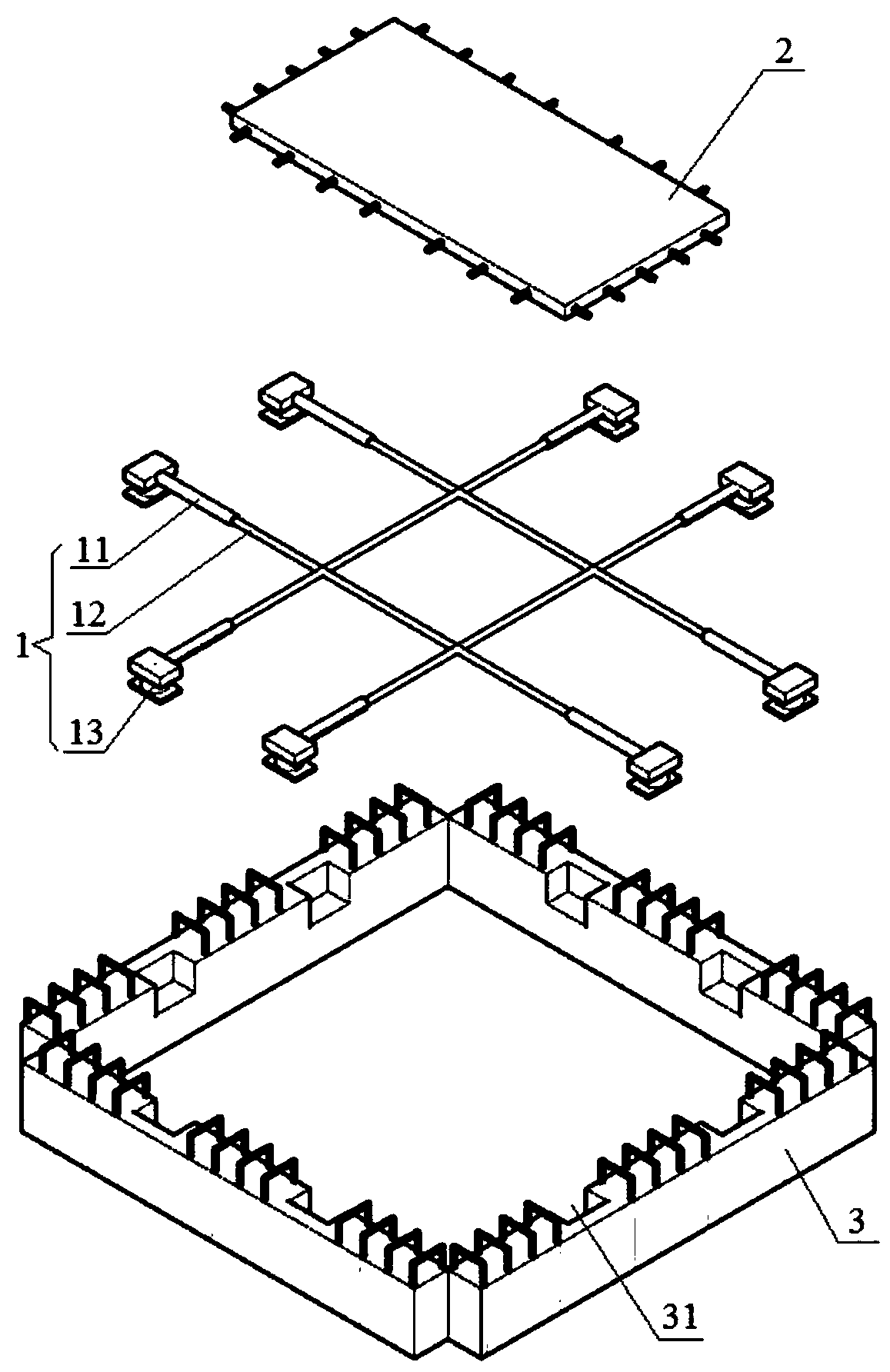

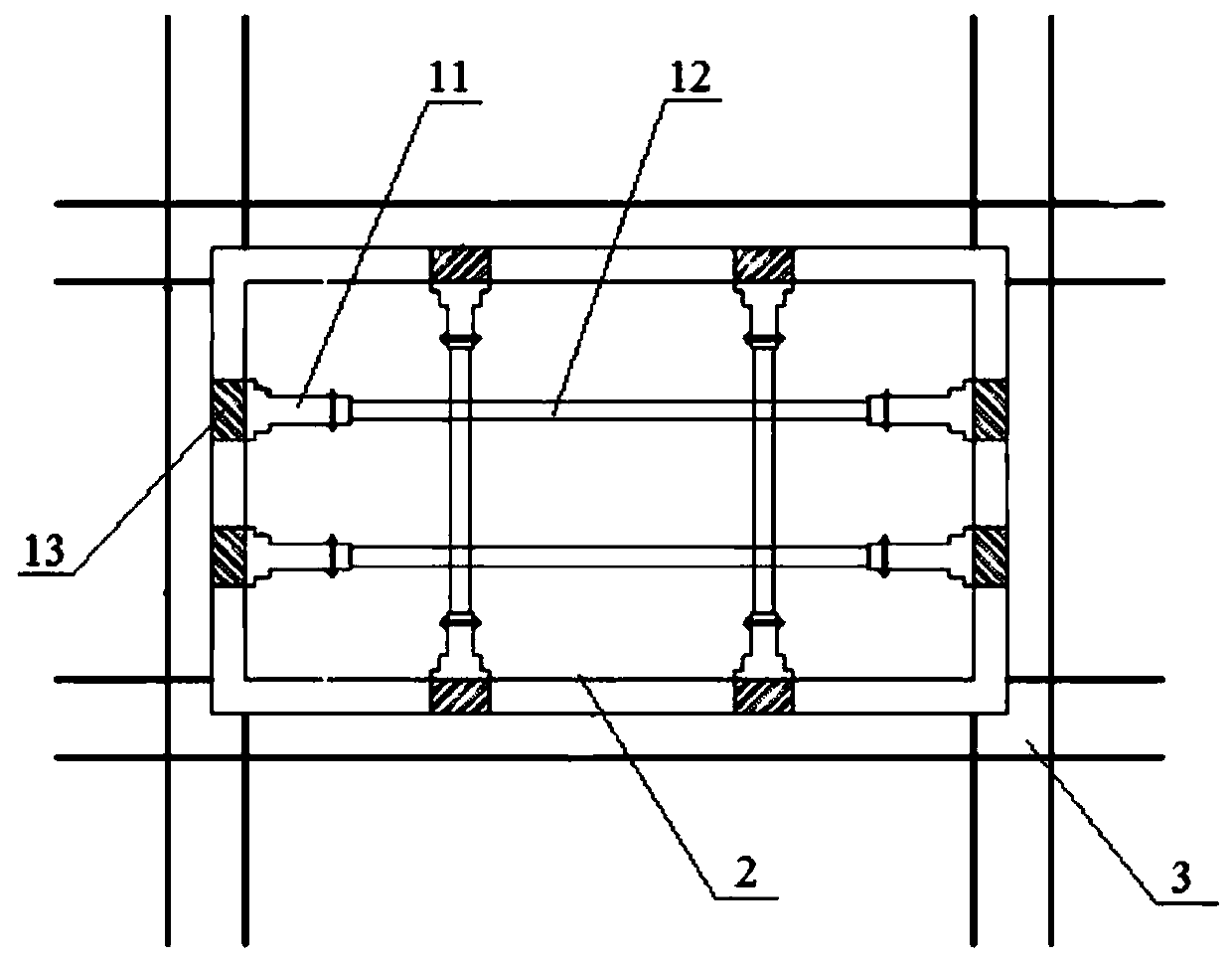

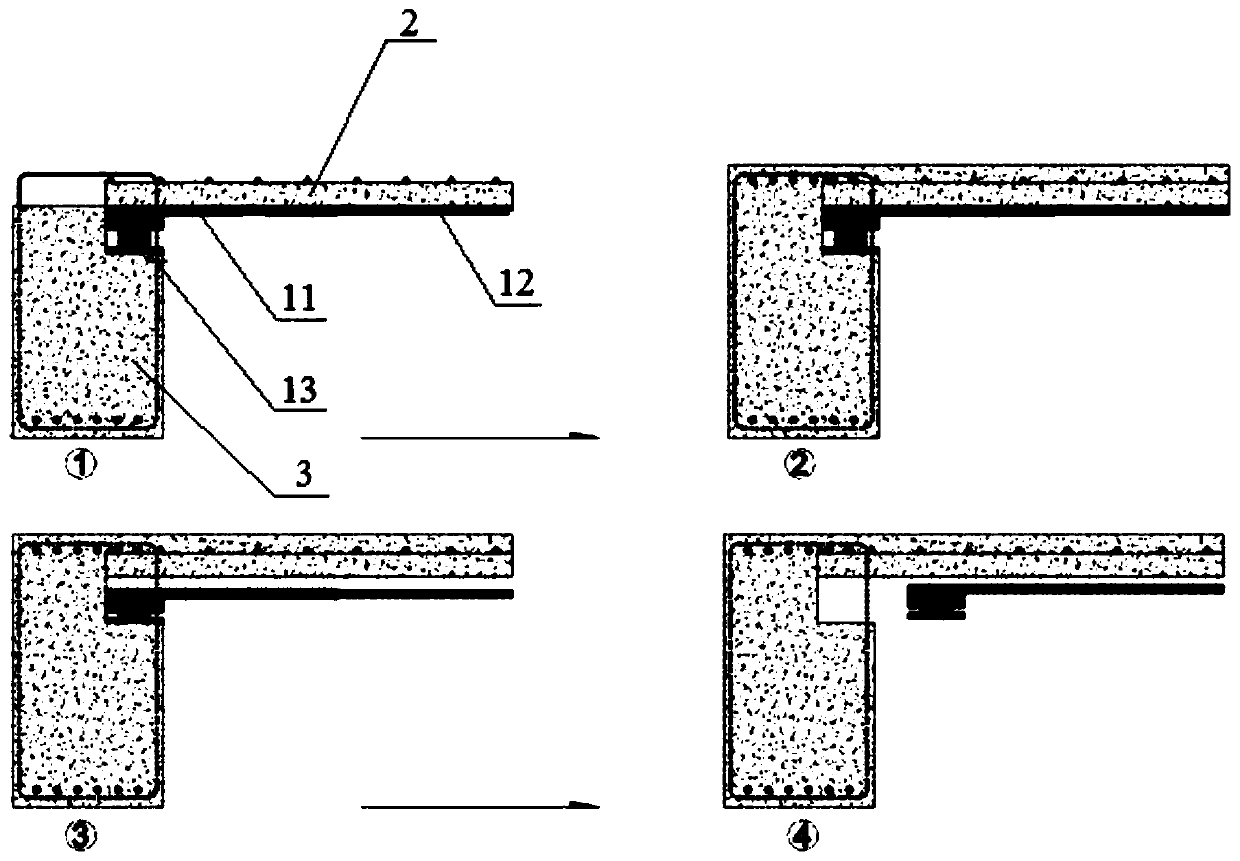

[0022] Such as figure 1 , figure 2 As shown, a flat support bracket for the construction of assembled prefabricated laminated slabs includes several pressure bearing rods 12, sleeve extension rods 11 installed at the ends of pressure b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com