Movable combustion furnace structure

A combustion furnace, mobile technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of low combustion efficiency, incomplete combustion, easy smoldering, etc., achieve high combustion efficiency, avoid smoldering, and not easy to smolder burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

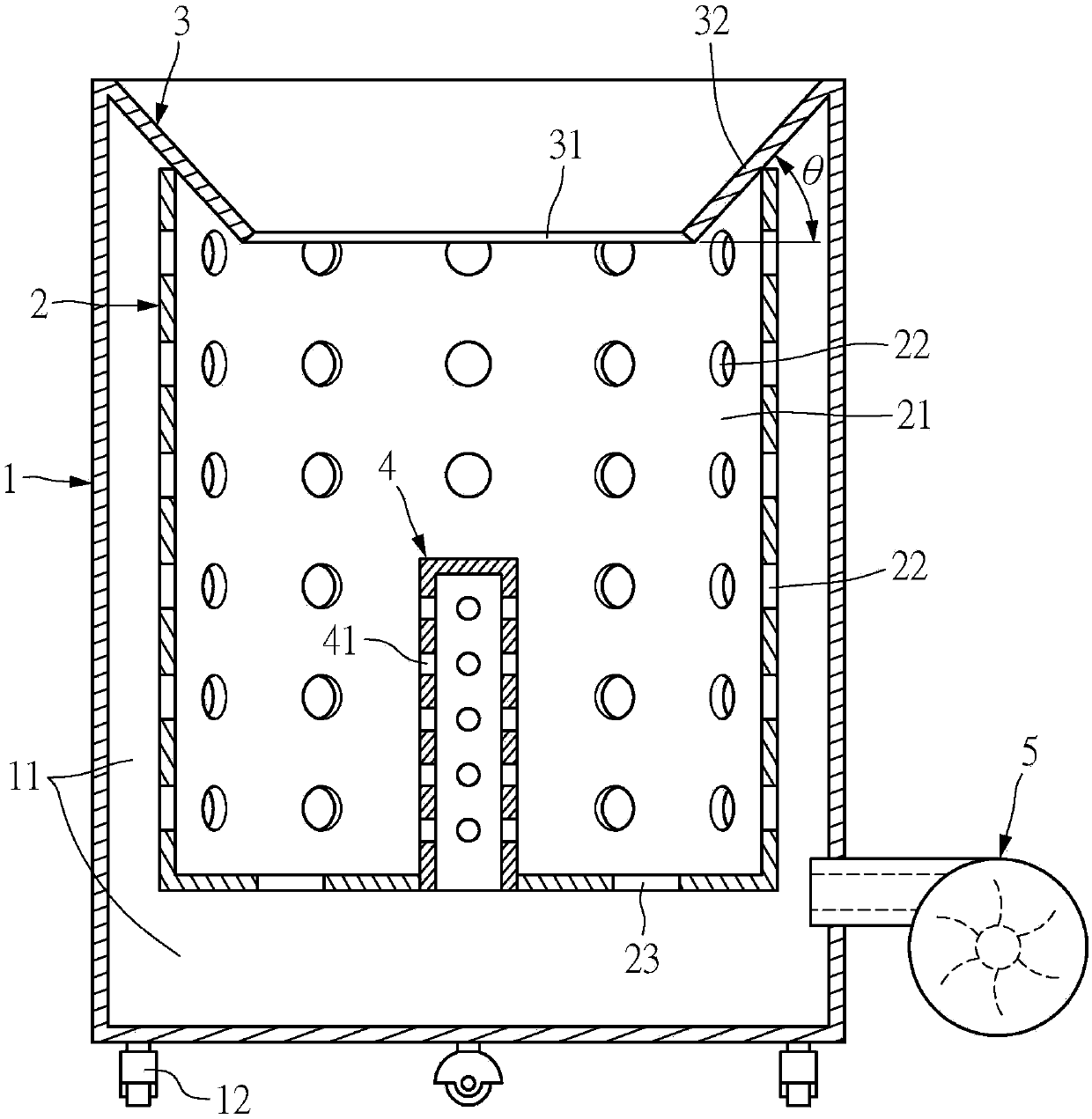

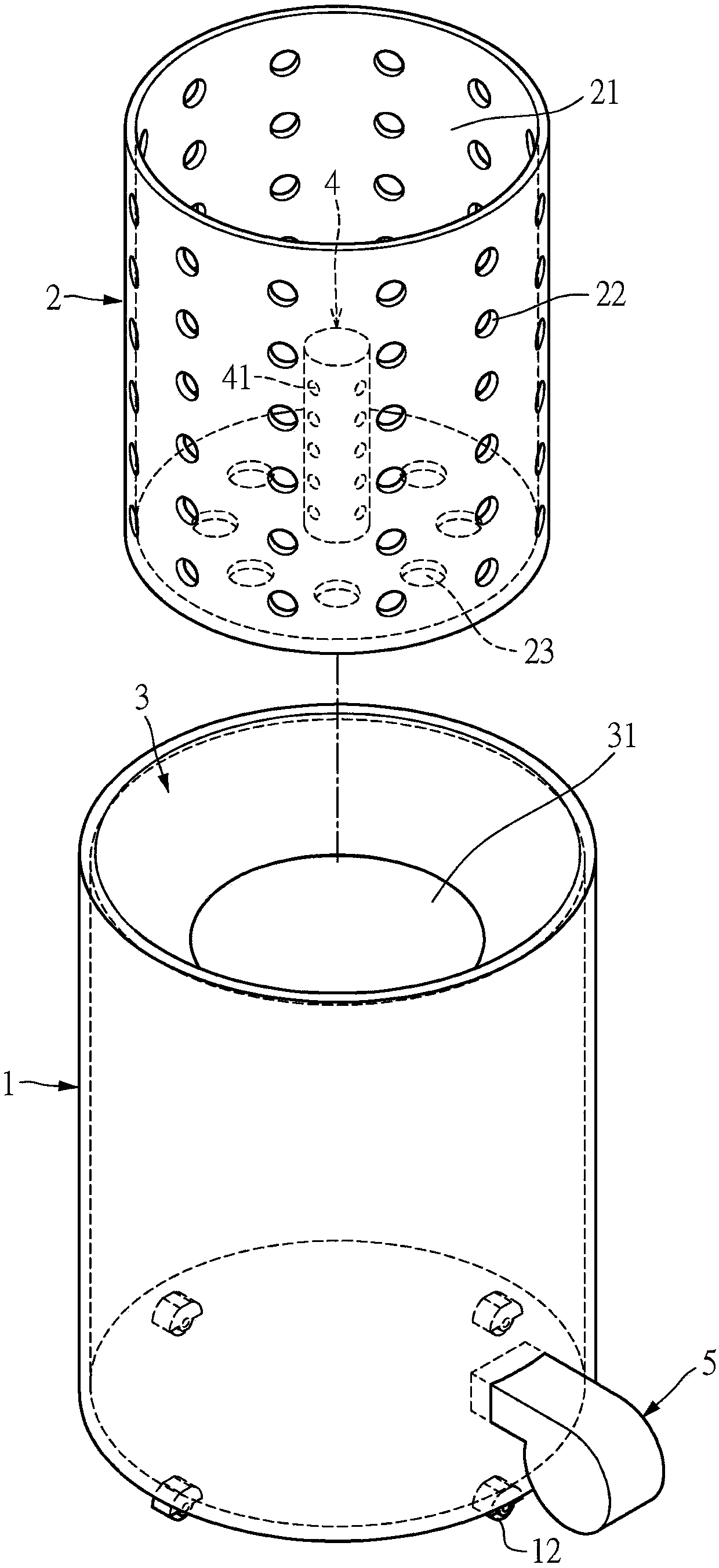

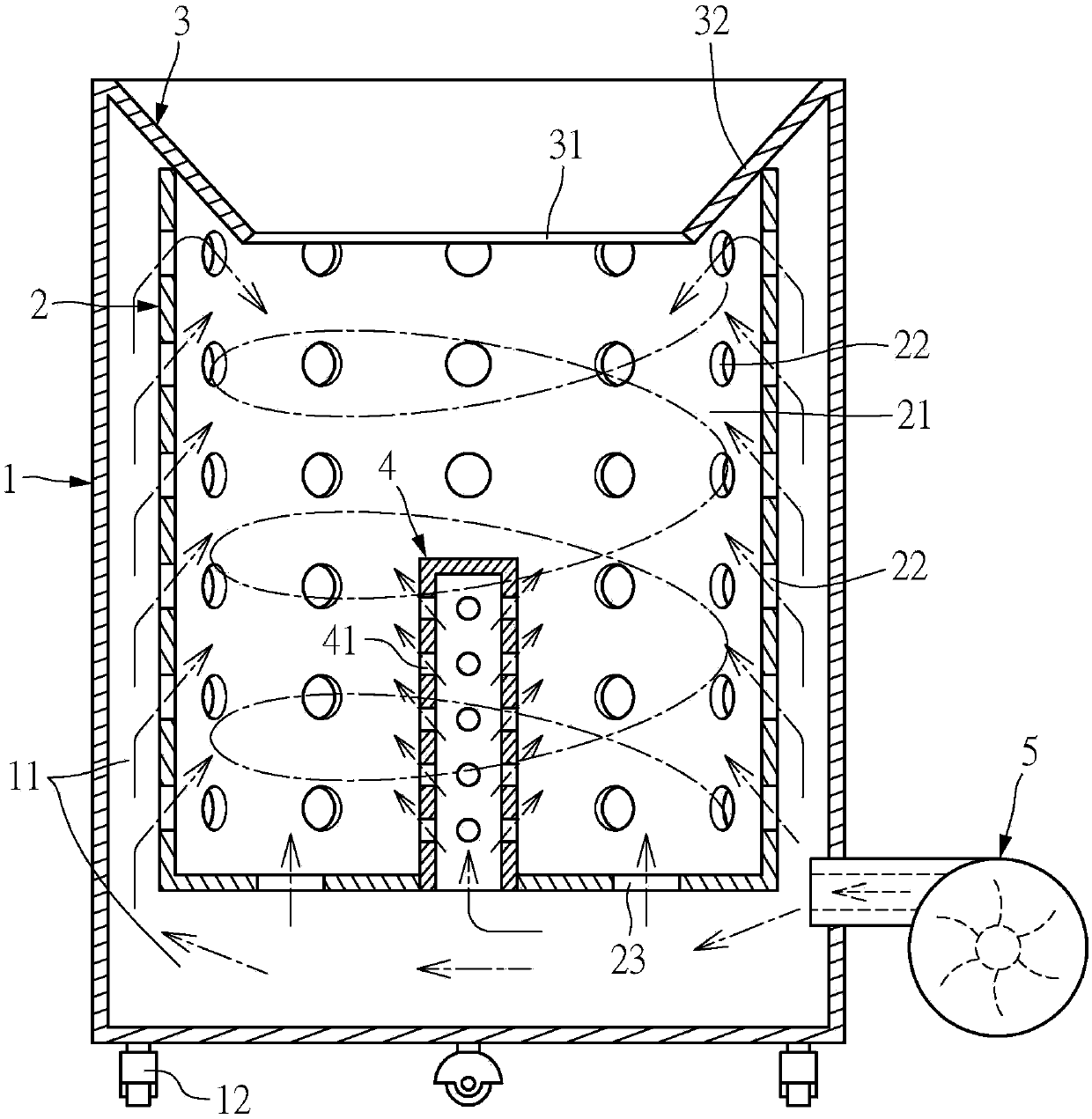

[0030] see figure 1 and figure 2 , The present invention provides a mobile combustion furnace structure, including an outer furnace body 1, an inner furnace body 2, a beveled flange 3, at least one flame-supporting tube 4 and a blower 5.

[0031] The outer furnace body 1 and the inner furnace body 2 are preferably made of metal or ceramic materials. The outer furnace body 1 and the inner furnace body 2 are hollow bodies, preferably hollow cylinders, but the outer furnace body 1 and the inner furnace body The shape and size of the body 2 are not limited. In this embodiment, the inner furnace body 2 is a hollow cylinder with an inner diameter of 310mm, 360mm, 450mm, 470mm, 800mm or 880mm. The inner furnace body 2 is arranged inside the outer furnace body 1, and an interval is formed between the outer furnace body 1 and the inner furnace body 2, that is, the side wall of the inner furnace body 2 and the bottom of the inner furnace body 2 and the outer furnace body 1 An air pas...

no. 2 example

[0041] see Figure 5 and Figure 6 , in the present embodiment, the bottom of this inner furnace body 2 also can have a row of ash opening 24, and the bottom of this inner furnace body 2 is pivotally provided with a sliding hopper 7, that is, one side of the sliding hopper 7 is hinged with a rotating shaft and hinged. The pivot assembly 25 is pivotally arranged at the bottom of the inner furnace body 2, so that the sliding hopper 7 can swing downward to open the ash discharge port 24 or swing upward to close the ash discharge port 24. When the sliding hopper 7 swings upwards to close the ash discharge port 24, it can be fixed by a fixing member 71, which can be various existing fixing members such as screws, latches or tenons. When the sliding hopper 7 swings downwards to open the ash discharge port 24, the sliding hopper 7 can be inclined to guide the ashes in the combustion chamber 21 to be discharged outwards to facilitate ash removal.

[0042] In addition, a door panel 1...

no. 3 example

[0044] see Figure 7 , in this embodiment, further, a vertical wall 33 is provided around the bottom of the flange opening 31, and the vertical wall 33 can be formed by the vertical downward extension of the lower end of the annular sloping plate 32, utilizing the vertical wall 33 Design, can more effectively avoid fly ash flying out when burning, not easy to produce pollution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com