Aerosol system for measuring volatility of biomass open burning particulate matters

A particle and biomass technology, applied in the field of aerosol system, can solve the problem of unable to measure the volatility of particles, and achieve the effect of avoiding insufficient combustion, long burning time and avoiding smoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

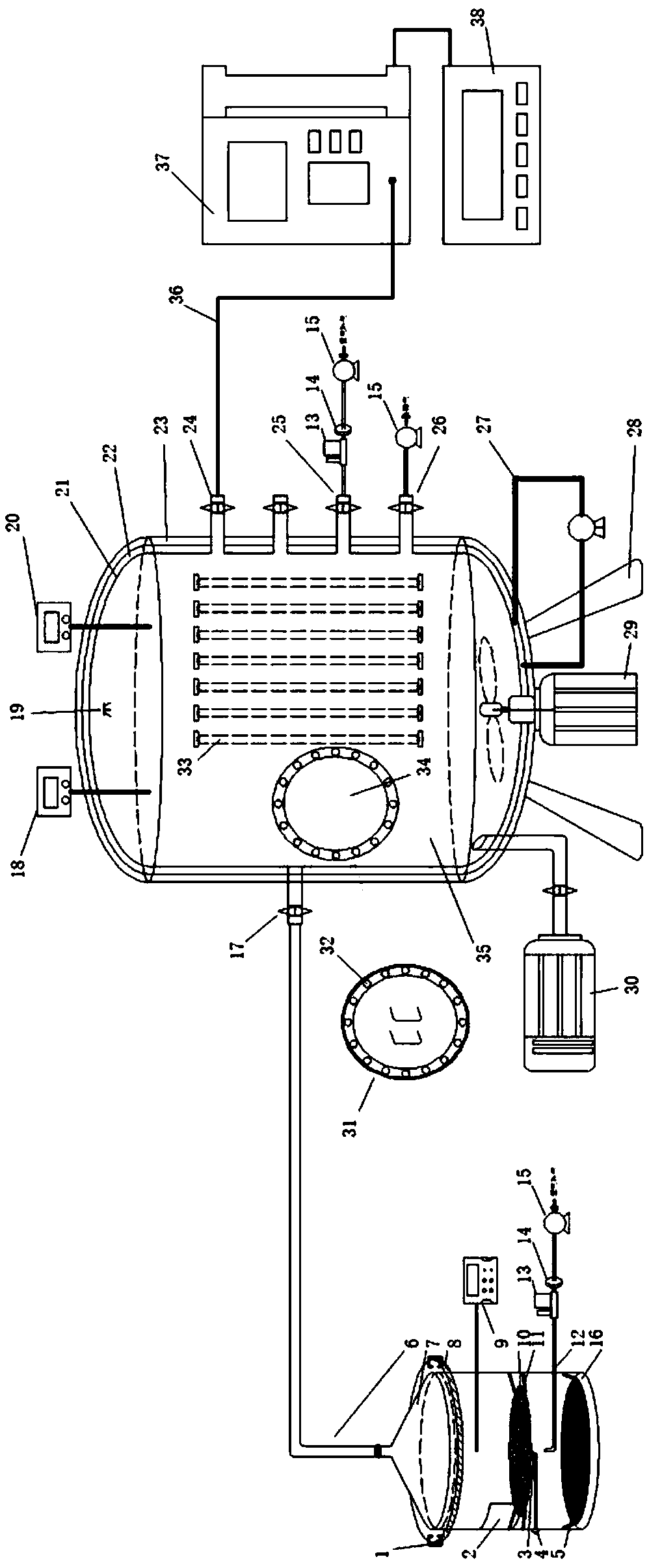

[0057] An aerosol system for measuring the volatility of biomass open-air combustion particles, including a sequentially connected combustion device for simulating open-air combustion of biomass, an aerosol smog box for simulating the emission of atmospheric pollutants into the atmosphere, and a particle volatility measurement device ;

[0058] The combustion device comprises a combustion furnace shell 16 with one end open and the other end sealed. The combustion furnace shell is a cylindrical shell with a height of 1000 mm and an inner diameter of 750 mm. The cover 7 is provided with a sealing ring 8 between the opening end of the combustion furnace shell and the furnace cover. The opening end of the combustion furnace shell and the furnace cover are fixedly connected by the sealing clip 1. The furnace cover is in the shape of an inverted funnel, and the top funnel of the inverted funnel shape The mouth is connected with the gas transmission pipe 6, and the gas transmission p...

Embodiment 2

[0065] Embodiment 1 is used to measure the application method of the aerosol system of the volatility of biomass open-air combustion particulate matter, comprising the steps as follows:

[0066] 1) Weigh 10.00g of clean biomass, put it on the combustion net of the combustion device after drying and spread it out, turn on the air supply pump, input particle-free air into the furnace shell through the air supply transmission pipe, and turn on the flue gas analyzer , observe the spectrum and record CO, CO 2 The initial concentration of the biomass is ignited, and the CO and CO are given in real time by the flue gas analyzer during the biomass combustion process. 2 concentration value and calculate the combustion efficiency, and adjust the air supply flow rate through the air supply pump to ensure that the combustion efficiency of biomass is greater than or equal to 0.9;

[0067] 2) Vacuumize the aerosol smog box through the vacuum pump, so that the pressure inside the aerosol sm...

experiment example

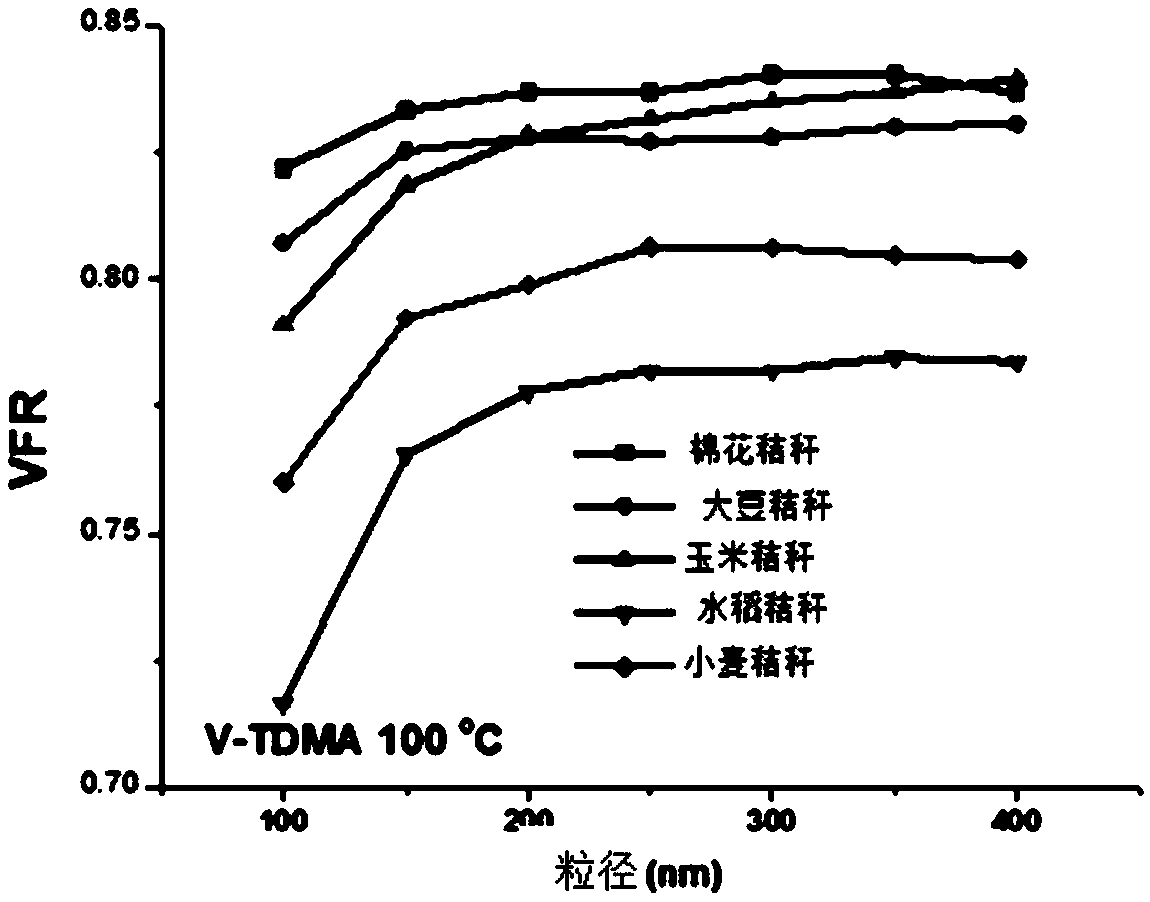

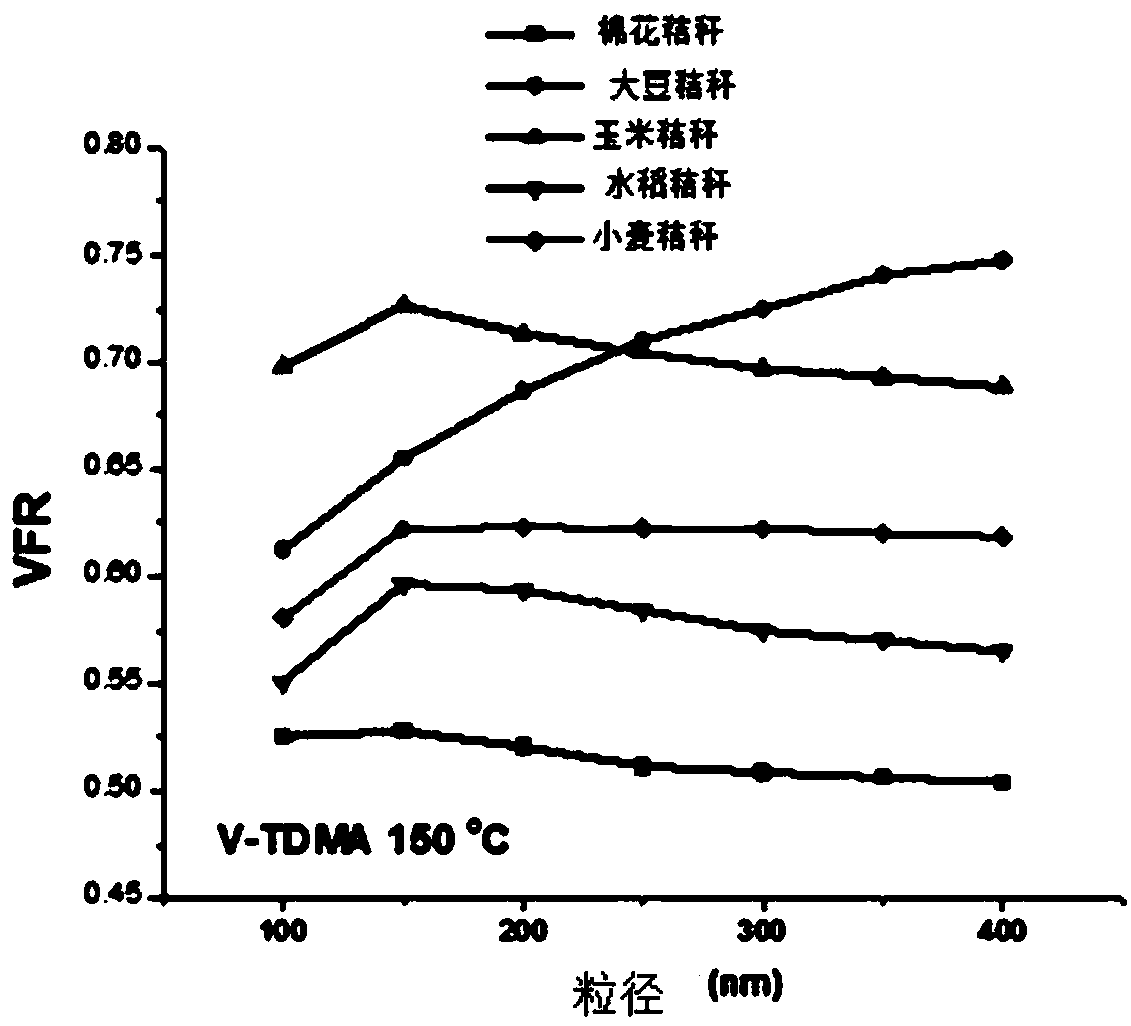

[0074] Experimental example: particle volatility test

[0075] Volatility affects the gas-solid distribution of aerosols and the generation of secondary aerosols, which in turn determines the atmospheric transport and cycle life of aerosol particles. Volatility is also an important indicator of aerosol thermal stability. The volatility of aerosol is usually expressed by VFR (volume fraction remaining), mass residual or thermogravimetric percentage MFR (massfraction remaining) after volatilization is stable. Utilize the system of the present invention to analyze the thermal stability of 100-400nm particulate matter produced by 5 kinds of straw combustion at 25-250°C and the density change before and after volatilization of the particulate matter. The volatility test results of the particulate matter produced by different straws at different temperatures are as follows: Figure 2-Figure 5 shown by Figure 2-Figure 5 As the temperature increased, the VFR decreased significantly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com