Biomass energy hot blast stove

A hot blast stove and biomass energy technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as excessive fluctuations in hot air temperature, incomplete combustion of fuel, and no combustion-supporting air supply device in the combustion chamber , to achieve the effect of smooth flow of hot air, no deformation in service life and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

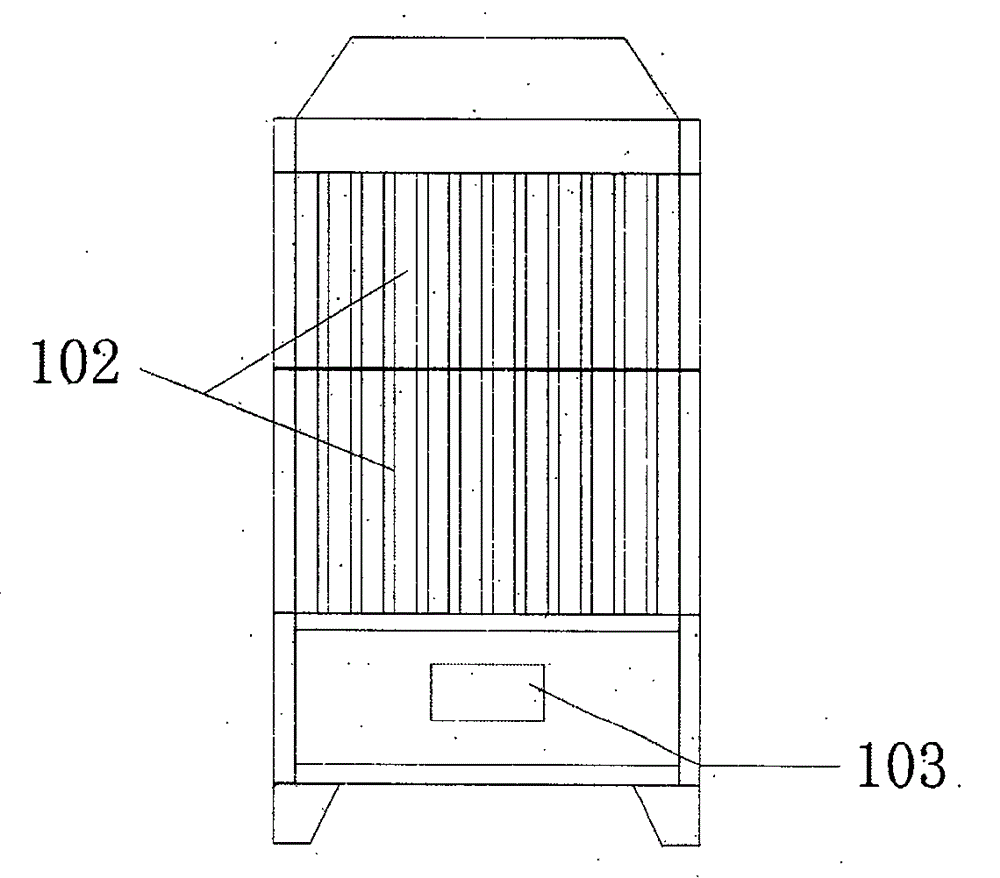

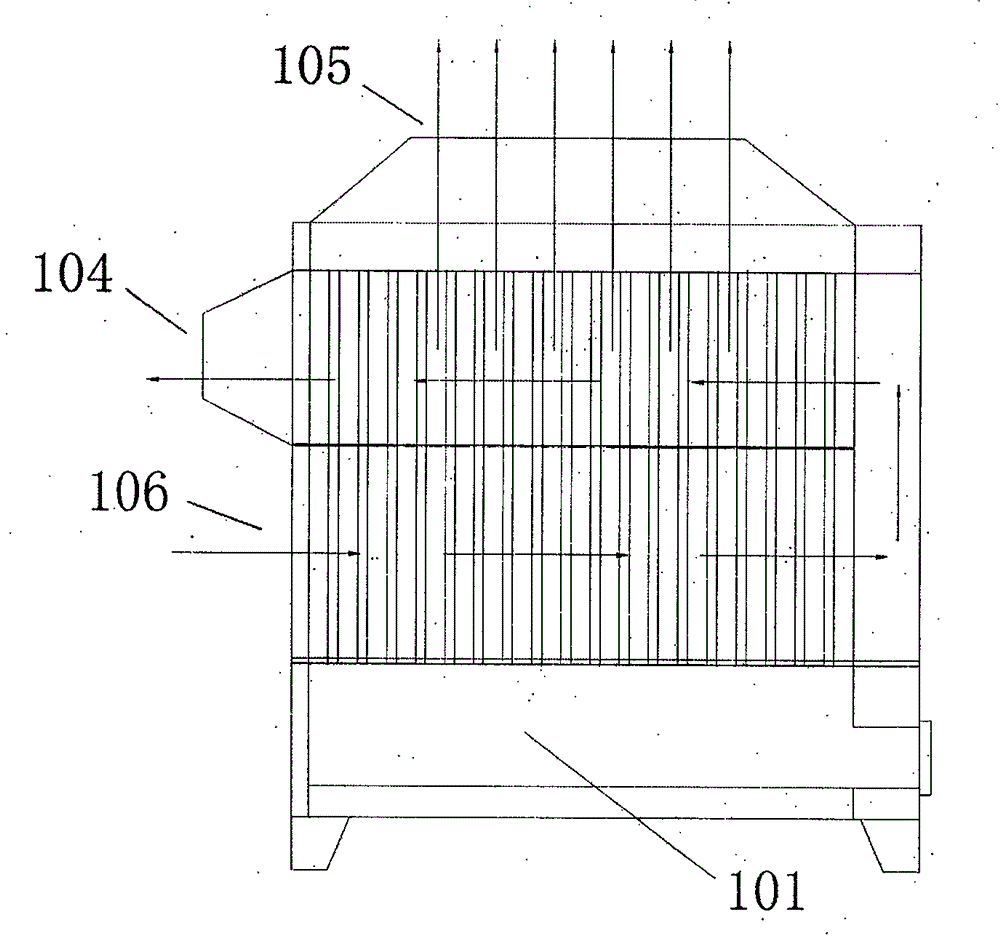

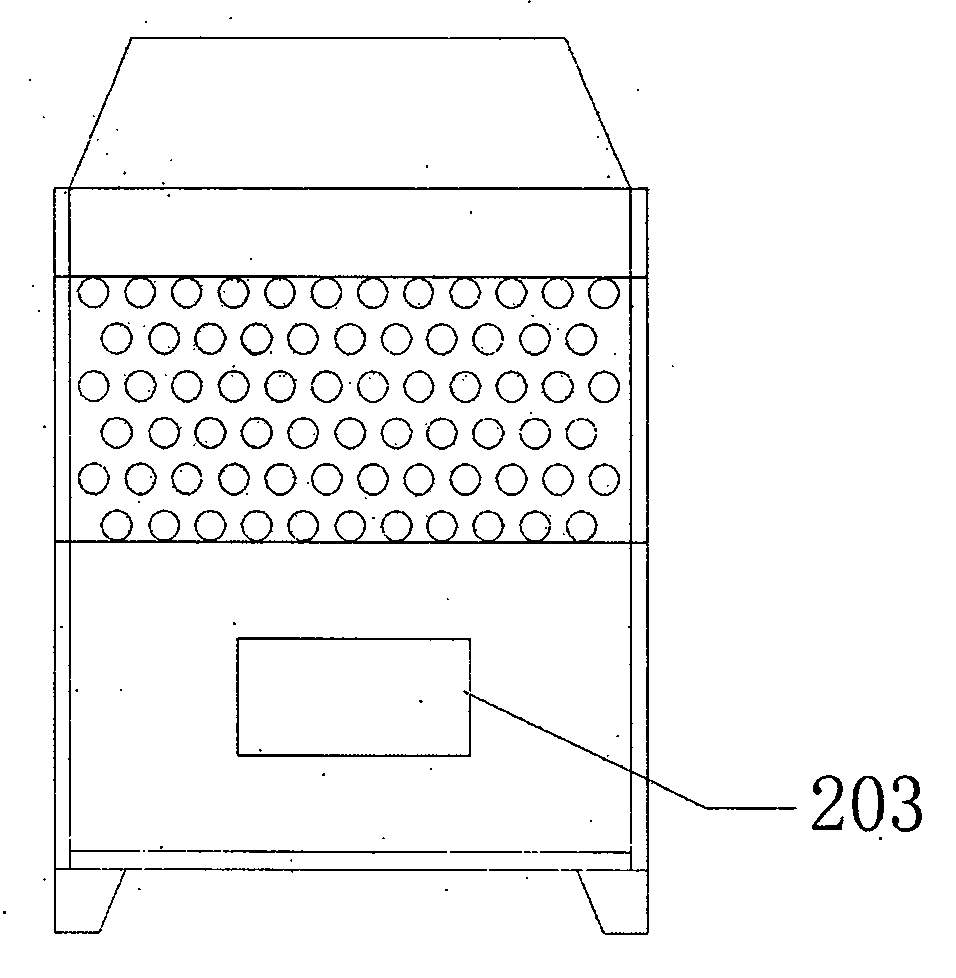

[0047] see image 3 The biomass energy hot blast stove described in this invention mainly includes a furnace 301, a heat exchanger 302, a base 303, a feeding device 304, a hot air bell mouth 305, wheels 306, an ash hopper 307, etc. The furnace 301 and the heat exchanger 302 Commonly placed on the top of the base 303; the furnace 301 is placed upright, and is connected with the heat exchange plate by an arc-shaped part 308 (the first wind box); the feeding device 304 and the feeding pipe 309 on the furnace 301 are in the form of a flange Connection; the wheels 306 are directly welded to the lower part of the base 303; the hot air bell mouth 305 is connected to the rear part of the heat exchanger 302 in the form of screw connection.

[0048] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com