Light heat-insulation flame-retardant composite natural polymer foam material as well as preparation method and application thereof

A natural polymer, flame retardant composite technology, applied in the field of foam materials, can solve the problems of high cost and complex preparation process, and achieve the effect of excellent sound absorption performance, wide source and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

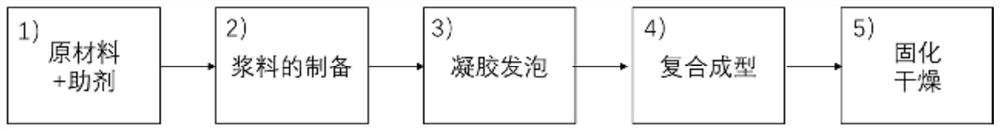

[0050] see figure 1 , the present invention provides a method for preparing a lightweight heat-insulating and flame-retardant natural polymer composite foam material, which is suitable for materials with sol-gel properties, comprising the following steps:

[0051] S1, raw material ratio, by weight ratio, provide 1-50 parts of natural polymer material solute, 50-99 parts of solvent water, 6-50 parts of auxiliary materials, and 0.01-10 parts of surfactant.

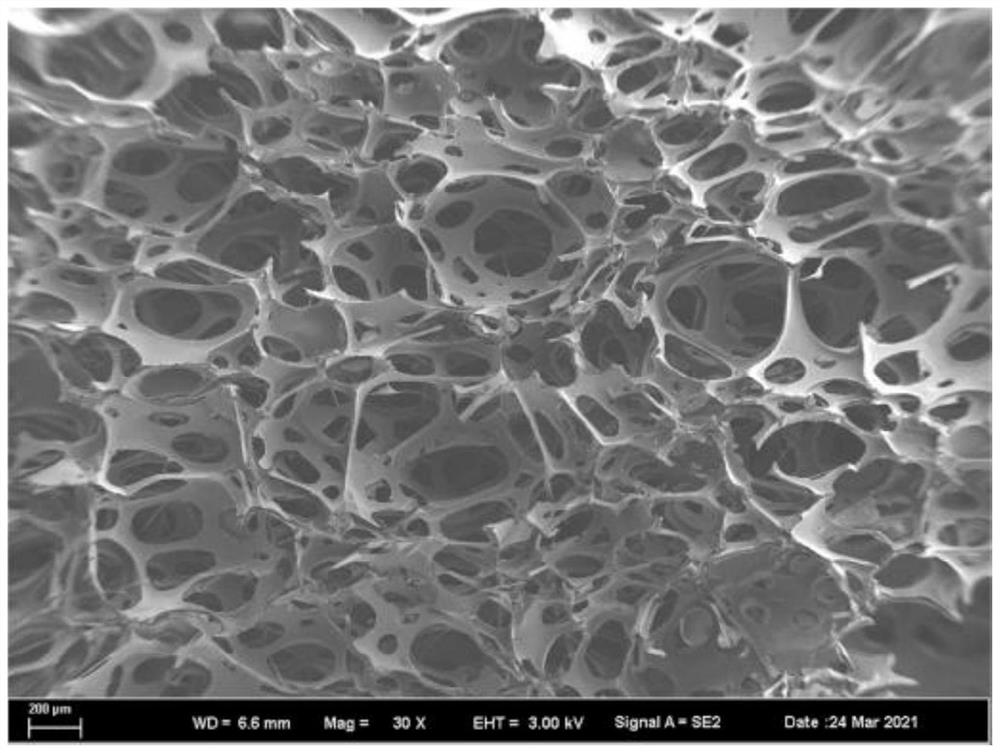

[0052] Natural polymers can be derived from animals, plants, microorganisms and marine organisms, and have sol-gel properties. Suitable examples include agar, carrageenan, alginic acid, pectin, gelatin, locust bean gum, gum arabic, modified cellulose , nanocellulose, modified starch and its derivatives, xanthan gum, gellan gum or other similar materials. Pure natural polymer foam material structure such as figure 2 shown.

[0053] The auxiliary materials include inorganic fillers and auxiliary agents, the inorganic fille...

Embodiment 1

[0074] A method for preparing a light heat-insulating and flame-retardant natural polymer composite foam material, comprising the following steps:

[0075] S1, the ratio of raw materials, by weight, provides 15 parts of natural polymer material solute, 85 parts of solvent water, 6 parts of auxiliary materials, and 5 parts of surfactant;

[0076] S2, slurry preparation, dissolving the solute in a solvent to form a sol, adding a surfactant, and stirring for 25 minutes to obtain a gel slurry;

[0077] S3, gel foaming, directly introducing a gas phase into the liquid phase of the gel slurry for foaming, and mixing the gas phase in the liquid phase uniformly and fully to obtain a liquid foam;

[0078] S4, compound molding, the liquid foam of S3 is stirred evenly and placed in the mold to obtain the liquid foam of preset shape;

[0079] S5, curing and drying, the liquid foam of S4 is solidified and dried to obtain a light heat-insulating and flame-retardant composite natural polyme...

Embodiment 2

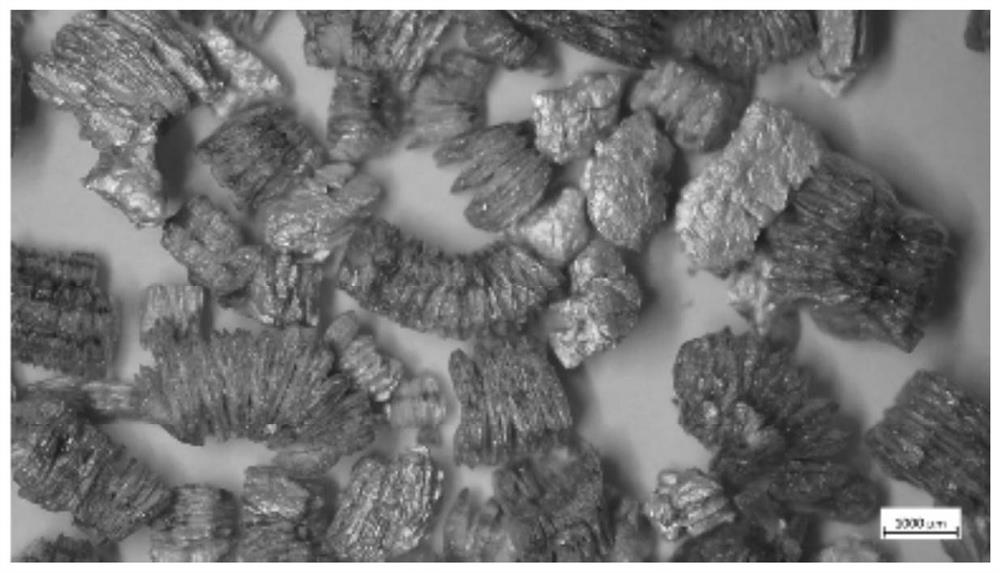

[0090] The only difference from Example 1 is that the selected inorganic filler is expanded perlite.

[0091] The structure of the natural macromolecule-expanded perlite composite material prepared in embodiment 2 is uniform, as micrograph ( Figure 7 ) shows that the perlite is uniformly dispersed in the pore structure of the natural polymer foam material; the natural polymer foam matrix is surrounded by the perlite, and the natural polymer cell structure is basically intact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com